1. Structural differences

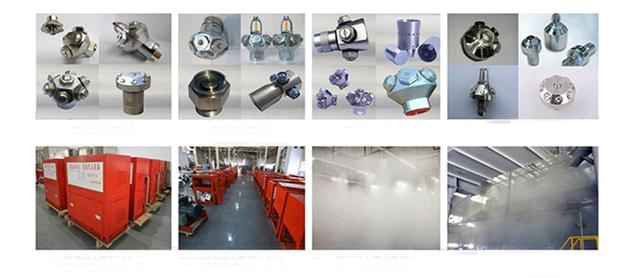

The spray head is composed of main body, nozzle, nozzle core, filter and other components. After the water under a certain pressure enters the sprinkler head through the filter, the pressure water is sprayed out from the nozzle hole at a high speed to achieve the fire extinguishing effect.

For the impact spray head, the water spray consists of a splash tray, a shunt cone and a frame body. The pressure water flows through the impact of the external water sputtering dish in the form of uniform conical foam dispersed in the set area.

2, the diameter of the fog is different

Fog diameter: the volume % characteristic diameter DV0.90 of the mist spray head is less than 1mm. That is to say, in the total volume of the spray liquid, fog below this diameter accounts for more than 90% of the volume.

Fog diameter: The diameter of the fog formed on the plane Dv0.50 is less than 200m, and Dv0.99 is less than 400m fog drops. In other words, 99 percent of the fog in this plane is smaller than 400 meters in diameter, and 50 percent is smaller than 200 meters in diameter.

The diameter of the mist sprayed by the high-pressure spray head is smaller than that of the water spray, so it is more suitable than the water spray fire extinguishing system for the higher requirements of flooding, such as libraries and archives.

3. Basic principles

The effects of design spray strength, protection area and spray head characteristics are considered comprehensively.

Spray water mist directly to completely cover the protected object.

The effective distance between the spray head and the protected object must not be greater than the effective range of the spray head.

4. Configuration mode

The flat placement method of the spray head can be rectangular or diamond.

When the configuration is rectangular, the distance between the spray heads should not be greater than 1.4 times the radius of the bottom circle of the spray cone of the spray heads;

When configured in diamond shape, the distance between the spray heads should not be greater than 1.7 times the radius of the bottom circle of the spray heads.

5, protection transformer spray head configuration requirements

If the protection object is an oil-immersed power transformer, the spray head must meet the following requirements:

The orifice, oil pillow, radiator and oil collecting hole of transformer rising seat should be protected by water mist nozzle;

The horizontal distance and vertical distance between spray heads shall meet the requirements of spray cone crossing.

When the protection object is Class A, B, C liquid and flammable gas tank, the distance between the spray head and the outer wall of the protection tank should be less than 0.7m.

When the protection object is a spherical can, the configuration of the spray head shall comply with the following regulations.

1. The mouth of the spray head must be towards the center of the ball;

2, the fog cone should be crossed with the direction of the latitude line, and the direction of the longitude line.

3. When the volume of the spherical tank is more than 1000m3, the fog cone should cross the direction of the latitude line and connect with the direction of the longitude line, but the distance between the rings above the equator should not exceed 3.6m;

4. Spray head should be set in the steel pillar of spherical tank without protective layer, tank level gauge, valve and other places for protection.