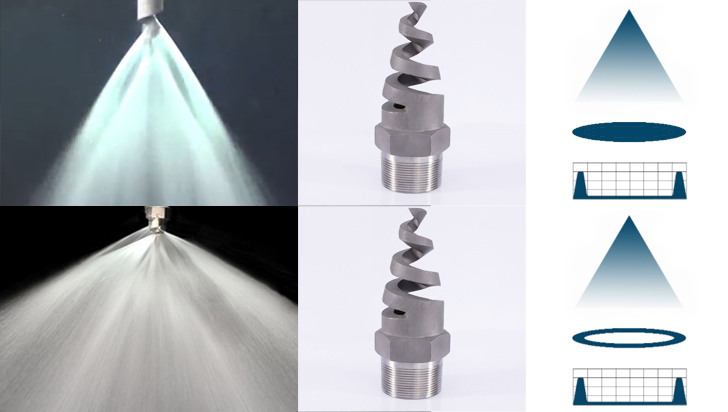

The principle of the spiral nozzle spray

The principle of the spiral nozzle is to use impact dispersion spray out, the internal spiral nozzle is not an unimpeded channel, water flow is by hitting the layered interface of the spiral, so that the product layer spray effect. Conventional spiral nozzle spray can be sprayed with 3 or 4 layers of spray interface, some even more layers of interface. Spray effect is: each interface is formed a cone spray surface, a spiral nozzle spray can be sprayed out at least 3-4 cone spray surface, generally can be sprayed out 6-7 spray surface, this will be the effect of ordinary full cone nozzle how many times. Spiral nozzle has full cone spray and hollow cone spray shape difference, in the spiral nozzle spray design, designers in the spiral nozzle spiral rod groove. Spiral nozzle with groove spray is a full cone spiral nozzle, no groove is a hollow cone nozzle.

The spiral nozzles also allow the liquid to spray over a larger area under low water pressure, and the liquid is deflected onto a spiral surface. The spray area of the nozzle is composed of a series of one or several continuous concentric hollow cone rings, and the spray shape is hollow cone and full cone.

The video demo of the spiral nozzle spraying

Two types of spiral nozzle spray

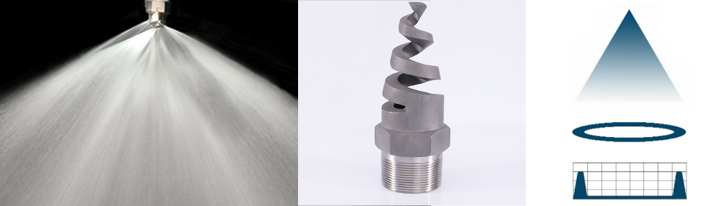

Spiral hollow cone nozzle spray

The spiral hollow cone nozzle produces a hollow cone spray pattern through its unique nozzle design. This type of spiral hollow conical nozzle can produce uniform distribution under a wide range of flow rates and pressures, the droplet size is small, because there is no internal blade, it is not easy to plug, large and unblocked flow channel and advanced flow control characteristics. Jet streams work best for an area requiring complete coverage.Spiral hollow conical nozzles available in materials

Brass, stainless steel, PVC, polypropylene, PTFE, other materials available on request.Spiral hollow conical nozzle spray Angle available

50, 60, 90, 120, 180Application of spiral hollow conical nozzle

Dust controlEvaporative cooling

The flue gas

The desulfurization

Gas cooling

Characteristic of spiral hollow conical nozzle

One-piece constructionNo internal parts

Clogging resistance

Fine spray

Energy efficient

Flow rate and injection Angle range is wide

Hexagonal body for easy installation

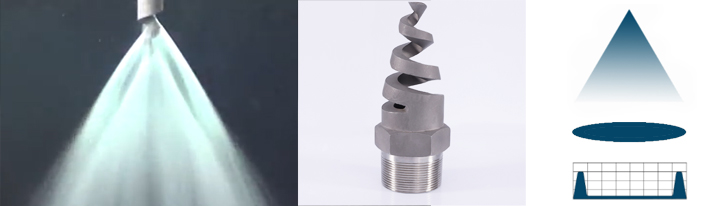

Spiral full cone nozzle spray

The spiral full cone nozzle produces a full cone spray pattern with multiple spray rings. Different from other full cone nozzles, the spiral full cone nozzles have no internal liquid splitter blades and no other parts. So the spiral full cone nozzle has anti - clogging performance, the overall structure.Available materials for spiral full cone nozzles

Brass,Stainless steel,Polyvinyl chloride (PVC),polypropylene,Teflon,Other materials available upon requestSpiral full cone nozzle spray Angle available

60 °, 90 °, 150 °, 170 °,Application of spiral full cone nozzle

inflatableChemical processing

Condenser spray

Put out the fire

Evaporative cooling

Gas washing

The desulfurization

Gas cooling

Features of spiral full cone nozzle

The overall structureNo internal parts

Clogging resistance

Energy efficient

Flow rate and injection Angle range is wide

Hexagonal body for easy installation

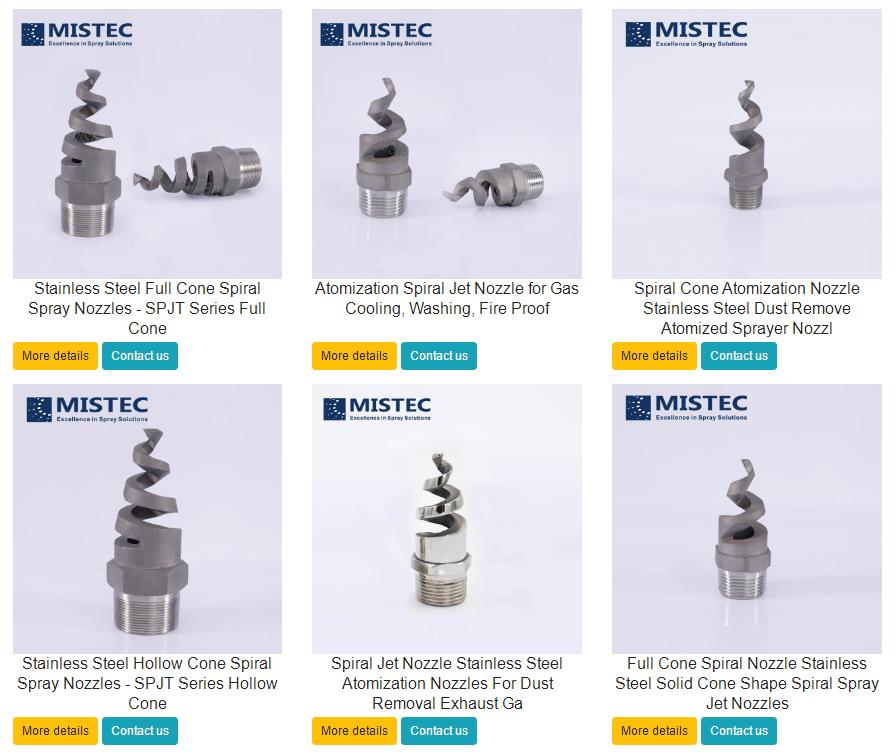

The use of spiral nozzle spray needs to be in accordance with the actual use of environmental requirements.

Our spiral nozzles are designed as one-piece with no internal blades and therefore have a high flow rate with almost no clogging, making them spiral jet nozzles. This means they can be used with a variety of liquids, require minimal maintenance, and have a long service life.