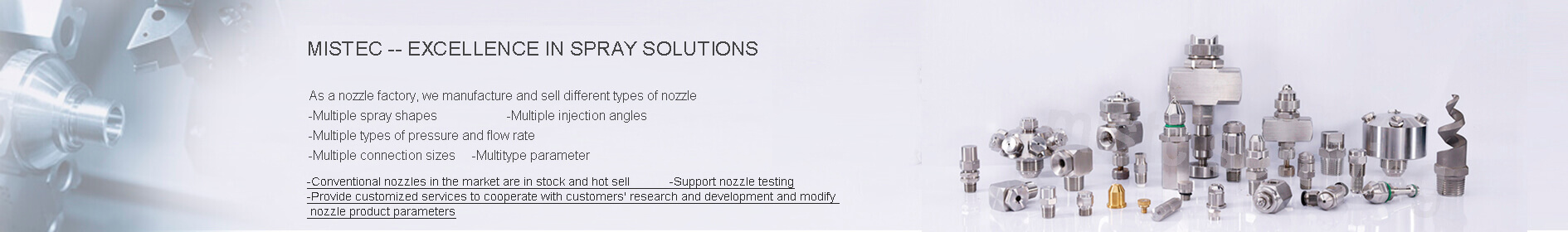

- Professional Spray Nozzles and Spraying Systems Manufacturer

- Provide you with excellent spray solutions

- Email:

info@mistec.cn

- Mob:

+8615816801107

- Tel:

+86(0)7698511 9952

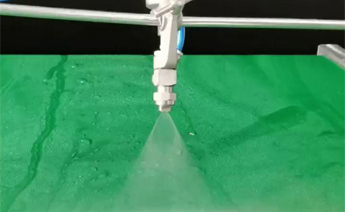

high pressure washing nozzle design for high pressure cleaning machine. The size of the nozzle area directly affects the cleaning effect. If the nozzle area is too large, the average kinetic energy will decrease. If the nozzle area is too small, it will produce serious backflow, which will also lead to a decrease in high pressure cleaning kinetic energy. Therefore, in order to give full play to the cleaning effect of the high pressure washer, it is necessary to calculate the corresponding high pressure washing nozzle area.

4, high pressure washing nozzle design has a single hole and porous. When used for cleaning pipes, attention should be paid to the use environment, and single or porous holes should be selected according to different environments. When cleaning hard stains, it is recommended to use a single-hole high pressure washing nozzle for design and cleaning, which can effectively clean stains; When cleaning soft stains, it is recommended to use a porous high pressure washing nozzle for design, which is more efficient.

5, the principle of high pressure washing nozzle is simply to use high pressure spray liquid to form a nozzle. The manufacturing material of the high pressure washing nozzle is made of high-strength metals such as tungsten carbide stainless steel, so that the nozzle will not wear out during high pressure spraying. high pressure washing nozzles are usually equipped with cleaning, atomizing, spraying functions and other equipment.

6, the high pressure washing nozzle is made of high strength material. In industry, the high pressure element is essential to the nozzle, and the nozzle can play an efficient industrial use through high pressure. The principle of the high pressure washing nozzle is to collect high pressure liquid and air in the nozzle by shrinking the cross section of the inner hole of the nozzle, and then quickly spray out, producing a high impact water flow, and then clean, cut and break industrial supplies, which is the cleaning principle of the high pressure washing nozzle.

7, high pressure washing nozzle with impact water cleaning, cutting, crushing, etc. In short, the principle of a high pressure washing nozzle is a device for high-speed water flow. The working principle of the pressure nozzle is to convert the pressure energy of high pressure water into kinetic energy by shrinking the cross section of the inner hole of the nozzle, and finally spray out of the high pressure washing nozzle in the form of high pressure water jet. Due to the principle of the high pressure washing nozzle, the nozzle has an impact force and is widely used in cleaning operations and steel cutting.

8, the principle of high pressure washing nozzle makes the spray have an impact, widely used in cleaning and cutting. The effect of high pressure washing nozzle spraying is that the spray particles are very small, which can increase the contact area between the surface area and the air, which is conducive to the evaporation of the droplets and the humidification effect. The size requirements of atomizing and humidifying nozzles are relatively large. If the droplets sprayed by the high pressure are equivalent to the particle size of the dust, the atomized particles sprayed by the high pressure washing nozzle will collide with each other like a ping-pong ball and move in the opposite direction to each other. Therefore, the spray droplets of the high pressure washing nozzle must be more than twice the particle size of the dust in order to capture the dust well. The particles get bigger, and eventually the dust falls.

1, whether the nozzle has mechanical strength;

2, whether it has wear resistance;

3, whether it has corrosion resistance;

4. Whether it is processable. Since the nozzle is a wearing part, tungsten carbide, artificial diamond and other cost-effective materials are generally used.

high pressure washing nozzle spray effect is good, can achieve dust removal effect. In short, the principle of a high pressure washing nozzle is to spray very subtle atomized particles through high pressure. And the high pressure spray impact is large, can be used for cleaning cutting field.

Nozzle specification refers to the length of the nozzle, usually related to the material and maximum pressure of the nozzle. In general, the high pressure washing nozzle is divided into two categories: metal nozzle and ceramic nozzle. Metal nozzle is often used in washing, cleaning, cooling, humidification, evaporation and other fields; Ceramic nozzle is suitable for spraying, spraying, smoke purification and other fields.

2. Materials

The choice of nozzle material determines the corrosion resistance, hardness and dimensional accuracy of the nozzle. Different materials are suitable for different occasions. Common nozzle materials are stainless steel, brass, carbide, ceramics and so on.

3. Maximum pressure

Maximum pressure refers to the maximum pressure that the nozzle can withstand. When purchasing nozzles, it is necessary to select the nozzle with the appropriate maximum pressure according to the actual use needs. Generally speaking, the maximum pressure of the high pressure washing nozzle can reach more than 1000bar.

4. Diameter of the spray hole

The diameter of the nozzle hole refers to the diameter of the center hole of the nozzle outlet, which directly affects the spray distribution. The smaller the diameter of the spray hole, the smaller the spray particles. The opposite is larger. Of course, this will also affect the flow of the nozzle, so it is necessary to choose according to actual needs.

2, avoid high temperature and high pressure use, so as not to make the nozzle premature aging, deformation or damage;

3, pay attention to cleaning and maintenance to extend the service life;

4, select the appropriate model and parameters, in order to obtain a good spray effect.

In summary, the selection and use of high pressure washing nozzle need to be considered according to the actual demand and injection effect. The parameters of the nozzle are directly related to the final spray effect, so it is necessary to carry out detailed understanding and comparison in order to choose the right high pressure washing nozzle.

4, high pressure washing nozzle design has a single hole and porous. When used for cleaning pipes, attention should be paid to the use environment, and single or porous holes should be selected according to different environments. When cleaning hard stains, it is recommended to use a single-hole high pressure washing nozzle for design and cleaning, which can effectively clean stains; When cleaning soft stains, it is recommended to use a porous high pressure washing nozzle for design, which is more efficient.

5, the principle of high pressure washing nozzle is simply to use high pressure spray liquid to form a nozzle. The manufacturing material of the high pressure washing nozzle is made of high-strength metals such as tungsten carbide stainless steel, so that the nozzle will not wear out during high pressure spraying. high pressure washing nozzles are usually equipped with cleaning, atomizing, spraying functions and other equipment.

6, the high pressure washing nozzle is made of high strength material. In industry, the high pressure element is essential to the nozzle, and the nozzle can play an efficient industrial use through high pressure. The principle of the high pressure washing nozzle is to collect high pressure liquid and air in the nozzle by shrinking the cross section of the inner hole of the nozzle, and then quickly spray out, producing a high impact water flow, and then clean, cut and break industrial supplies, which is the cleaning principle of the high pressure washing nozzle.

7, high pressure washing nozzle with impact water cleaning, cutting, crushing, etc. In short, the principle of a high pressure washing nozzle is a device for high-speed water flow. The working principle of the pressure nozzle is to convert the pressure energy of high pressure water into kinetic energy by shrinking the cross section of the inner hole of the nozzle, and finally spray out of the high pressure washing nozzle in the form of high pressure water jet. Due to the principle of the high pressure washing nozzle, the nozzle has an impact force and is widely used in cleaning operations and steel cutting.

8, the principle of high pressure washing nozzle makes the spray have an impact, widely used in cleaning and cutting. The effect of high pressure washing nozzle spraying is that the spray particles are very small, which can increase the contact area between the surface area and the air, which is conducive to the evaporation of the droplets and the humidification effect. The size requirements of atomizing and humidifying nozzles are relatively large. If the droplets sprayed by the high pressure are equivalent to the particle size of the dust, the atomized particles sprayed by the high pressure washing nozzle will collide with each other like a ping-pong ball and move in the opposite direction to each other. Therefore, the spray droplets of the high pressure washing nozzle must be more than twice the particle size of the dust in order to capture the dust well. The particles get bigger, and eventually the dust falls.

How to choose high pressure washing nozzle

When selecting a high pressure washing nozzle, the following factors should be considered:1, whether the nozzle has mechanical strength;

2, whether it has wear resistance;

3, whether it has corrosion resistance;

4. Whether it is processable. Since the nozzle is a wearing part, tungsten carbide, artificial diamond and other cost-effective materials are generally used.

high pressure washing nozzle spray effect is good, can achieve dust removal effect. In short, the principle of a high pressure washing nozzle is to spray very subtle atomized particles through high pressure. And the high pressure spray impact is large, can be used for cleaning cutting field.

First, the common high pressure washing nozzle model

The common high pressure washing nozzle models are fan nozzle (fan), cone nozzle (conical), fan hole nozzle (fan-hole), round hole nozzle (round hole), spray nozzle (atomization), jet nozzle (injection), etc. Different nozzles have different applications and effects, and need to be selected according to actual needs.Second, nozzle parameters and effects

1, nozzle specificationsNozzle specification refers to the length of the nozzle, usually related to the material and maximum pressure of the nozzle. In general, the high pressure washing nozzle is divided into two categories: metal nozzle and ceramic nozzle. Metal nozzle is often used in washing, cleaning, cooling, humidification, evaporation and other fields; Ceramic nozzle is suitable for spraying, spraying, smoke purification and other fields.

2. Materials

The choice of nozzle material determines the corrosion resistance, hardness and dimensional accuracy of the nozzle. Different materials are suitable for different occasions. Common nozzle materials are stainless steel, brass, carbide, ceramics and so on.

3. Maximum pressure

Maximum pressure refers to the maximum pressure that the nozzle can withstand. When purchasing nozzles, it is necessary to select the nozzle with the appropriate maximum pressure according to the actual use needs. Generally speaking, the maximum pressure of the high pressure washing nozzle can reach more than 1000bar.

4. Diameter of the spray hole

The diameter of the nozzle hole refers to the diameter of the center hole of the nozzle outlet, which directly affects the spray distribution. The smaller the diameter of the spray hole, the smaller the spray particles. The opposite is larger. Of course, this will also affect the flow of the nozzle, so it is necessary to choose according to actual needs.

Third, use precautions

1, avoid excessive force, so as to avoid deformation or damage;2, avoid high temperature and high pressure use, so as not to make the nozzle premature aging, deformation or damage;

3, pay attention to cleaning and maintenance to extend the service life;

4, select the appropriate model and parameters, in order to obtain a good spray effect.

In summary, the selection and use of high pressure washing nozzle need to be considered according to the actual demand and injection effect. The parameters of the nozzle are directly related to the final spray effect, so it is necessary to carry out detailed understanding and comparison in order to choose the right high pressure washing nozzle.

Get a Consult For Your Needs

We have a number of nozzle engineers with many years of experience, we can provide you with nozzle or spray system related expertise.

Are you interested in nozzle or spray system parameters, flow rate, pressure, orificket, connection components, thread size, etc.?

Or interested in application, sample test, installation, after-sales, service?

Or are you interested in price, delivery time, technical guidance?

All the relevant knowledge, our engineers will communicate with you.

Contact Us

Are you interested in nozzle or spray system parameters, flow rate, pressure, orificket, connection components, thread size, etc.?

Or interested in application, sample test, installation, after-sales, service?

Or are you interested in price, delivery time, technical guidance?

All the relevant knowledge, our engineers will communicate with you.

OUR SERVICE

Why chosse us

01 - Professional nozzle manufacturing team

Many years of nozzle manufacturing team, r&d personnel, manufacturing personnel, engineers and so on.

02 - Advanced manufacturing equipment

Advanced manufacturing equipment ensures the quality of nozzles manufactured by us.

03 - The fast delivery

Our nozzle packaging fast, shipping fast, can be by sea, air, express and other ways to quickly reach customers.

04 - Timely communication

We have professionals to answer timely information about nozzles, such as installation, replacement, repair, cleaning and so on.

Nozzles Article

Nozzle technology and information

Get in Touch

Contact Us

You can ask for free information about spray nozzles, such as sizes, type, price, shipping, installation, maintenance, customization, payment method, returns etc.

Our nozzle engineer will contact you as soon as possible to reply to your message. thanks

- 1. High quality nozzle

- 2. Fast shipping, fast express, air freight, etc

- 3. Manufacturer direct sales, factory prices, more discounts

- 4. Nozzle engineer timely communication, reply messages

Get it information

Contact info

For any kind of query, contact us with the details below.

- Contact: Mr zhang

- +86 15816801107

- +86 (0) 7698511 9952

- info@mistec.cn

- No. 10 Huaide Daxin Rd, Humen Town, Dongguan City 523927, Guangdong Pro. CHINA

- Opening Hours : 24 hour