First, the key factors of atomization performance of the atomizer

The atomization performance of the atomizer is affected by many factors, including the type of atomizer, nozzle diameter, liquid viscosity, liquid surface tension, etc. Among them, the most important factors affecting the spray effect are the design and parameters of the sprayer.Second, the method of improving the atomization performance of the atomizer

1. Choose the right sprayer

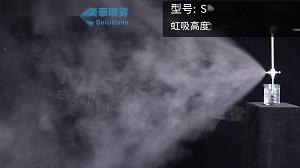

Different sprayer types correspond to different atomization effects, and the appropriate sprayer needs to be selected according to specific requirements. Generally speaking, the compressed air sprayer is easy to use and control, and can meet the requirements of large flow rate, but the droplets are coarse and unevenly distributed; The ultrasonic atomizer droplets are delicate, but the organic liquid is easy to corrode the ultrasonic vibration sheet. Therefore, it is necessary to select the appropriate sprayer according to the specific process requirements.

2. Adjust sprayer parameters

In the working process, the atomizing performance of the atomizer can be improved by adjusting the parameters of the atomizer properly. Specifically, the parameters of nozzle diameter, accuracy, nozzle Angle, nozzle distance and gas pressure are adjusted to achieve the desired atomization effect.3. Change the characteristics of the spray liquid

Changing the characteristics of the spray liquid is an important means to improve the atomization effect of the atomizer. For example, increasing the surface tension of the liquid can reduce the size of the droplets, but not too much, otherwise it is easy to produce foam.