The nozzle is usually classified according to the atomization method, which can be divided into:

(1) Low pressure fuel nozzle This nozzle is used to atomize fuel oil by the power of burning air. Its advantage is that the atomization power consumption is lower, the atomization quality is better, the disadvantage is that the nozzle itself has a complex structure, the air preheating temperature is limited, the nozzle specifications are small, it is suitable for small heating furnace without superheated steam.

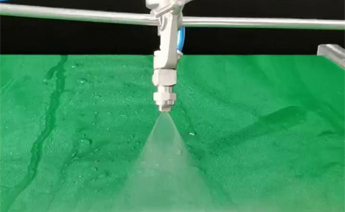

(2) The high-pressure fuel nozzle oil is atomized by using high-pressure superheated steam or compressed air, and the atomization quality is good and stable. The air for combustion is not directly in contact with the oil nozzle, so the air preheating is not limited, the adjustment range is relatively large, and it is easy to automate in centralized control and air-fuel ratio adjustment. The disadvantage is that the atomizing agent consumes a little more energy. The nozzle is suitable for large and medium-sized heating furnaces or general heating furnaces with superheated steam supply.

(3) Mechanical atomization nozzle Rotary cup nozzle is a typical mechanical atomization nozzle, it is a high-speed rotating cup-shaped device, the oil in the rotating cup into a layer of oil film close to the cup wall, through the mouth of the cup centrifugal flight and atomization. Because of some rotating mechanism, the structure of the nozzle is relatively complex, and the Angle of the atomizing torch is too large, and it is rarely used in the heating furnace.

Nozzle classification and driving mode

A, single point fuel injection nozzle

Single-point nozzle refers to the nozzle with only one electromagnetic coil, which is controlled by the electronic control unit to the electromagnetic coil. When the electromagnetic coil is subjected to current, the nozzle will be opened to complete the process of oil injection. The nozzle is simple in structure and cheap in price, but it is easy to lead to fuel waste and environmental pollution because it can not fine control the amount of fuel injection.

Two, multi-point fuel injection nozzle

The multi-point nozzle refers to the nozzle with multiple electromagnetic coils, each electromagnetic coil controls an independent nozzle, which can achieve fine control of the fuel injection amount, thereby improving the fuel utilization and combustion efficiency. However, due to the need for multiple electromagnetic coils to control the fuel injection, the cost of the multi-point nozzle is much higher than that of the single-point nozzle.

Third, common rail fuel nozzle

Common rail nozzle refers to the nozzle using high pressure common rail system. The pressure inside the nozzle is provided by the common rail system, and the injection time and amount of oil are controlled by the electromagnetic coil. The nozzle allows for more precise fuel flow control and multiple stages of fuel injection, improving fuel efficiency and engine performance while also reducing exhaust emissions. However, common rail systems require higher costs and are more difficult to maintain.

In summary, different types of fuel injectors have their own unique advantages and disadvantages. According to the actual demand and economic considerations, choosing the right fuel injection nozzle can better meet the operation requirements of the engine.