The core component of the sprayer is the nozzle, which determines the effect and efficiency of the spray. The nozzle design is often very fine, with specific channels and structures inside so that the liquid can pass smoothly and form a mist at the exit.

When the liquid is fed into the nozzle, it first passes through a contraction section, which gradually decreases in diameter. In this process, the flow rate of the liquid will gradually increase, and the pressure will increase accordingly. As the liquid continues to flow, it comes to a section that suddenly expands, which is called the diffusion section. Here, due to the sudden widening of the flow channel, the flow rate of the liquid will be rapidly reduced, and the pressure will be greatly reduced.

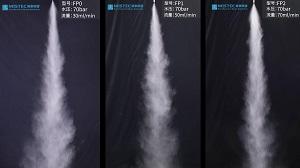

This rapid change in flow rate and pressure causes the liquid to form a high-speed jet at the outlet of the diffusion section. When the high-speed jet leaves the nozzle, it will be subjected to the resistance of the surrounding air, resulting in violent turbulence and shear force. The action of these forces causes the jet to be rapidly broken into a large number of tiny droplets, forming the spray effect we see.

In addition to the design of the nozzle, the spray effect of the sprayer is also affected by other factors. For example, the physical properties of the liquid (such as viscosity, surface tension, etc.), the working pressure of the sprayer, the distance between the nozzle and the target, and the spray speed will have an impact on the spray effect.

In practical applications, sprayers need to be adjusted and optimized according to different use scenarios and needs. For example, in agriculture, sprayers need to ensure that pesticides or fertilizers can be evenly covered on crop leaves to achieve the best control or yield increase effect. In the medical field, nebulizers are needed to ensure that drugs are accurately and evenly sprayed onto the patient's respiratory tract or skin to achieve effective treatment.

With the continuous progress of science and technology, the design and performance of sprayers are also constantly improving. The new sprayer not only has a better spray effect, but also has a significant improvement in energy saving, environmental protection, convenient operation and so on. For example, some new agricultural sprayers use intelligent control systems that automatically adjust the spray volume and speed according to crop growth and weather conditions, enabling more accurate and efficient spraying operations.

In short, the atomizer disperses the liquid into small droplets through the special design of the nozzle and the principle of fluid dynamics. The spray effect is affected by many factors and needs to be optimized and adjusted according to the actual application scenario. With the continuous development of science and technology, the performance and function of the sprayer are also constantly improving, providing a more convenient and efficient solution for applications in various fields.