Air atomizing nozzle is the use of compressed air and liquid impact friction, liquid produce very uniform and small atomizing effect, the average diameter of atomizing particles reaches 50 microns and below.

General application of air atomizing nozzle

The application field of atomizing nozzle is very wide, there are different applications in different industries. Can spray irrigation in agriculture, in industrial application can be used to spray humidification, lubrication, disinfection, such as environment can sulfur removal in the desulfurization tower, in power plants, chemical plants can be used to dry fog dust suppression, at the same time can also be used in extinguishing fire industry, in real life, can be used in the humidifying, disinfection, flavoring, etc.1) Paper industry: pulp moisture control, release agent spray, corrugated to prevent bending, etc.

2) Plastic industry: electrostatic preventive spray, coated film, etc.

3) Steel industry: plate, pipe cooling, etc.

4) Textile industry: moistening yarn and cloth, etc.

5) Printing industry: concave plate printing rotary machine to prevent thermal ripples, etc.

6) Automobile industry: trolley cooling of oven on coating line, etc.

7) Environmental protection industry: humidification, disinfection, dust removal and other aspects.

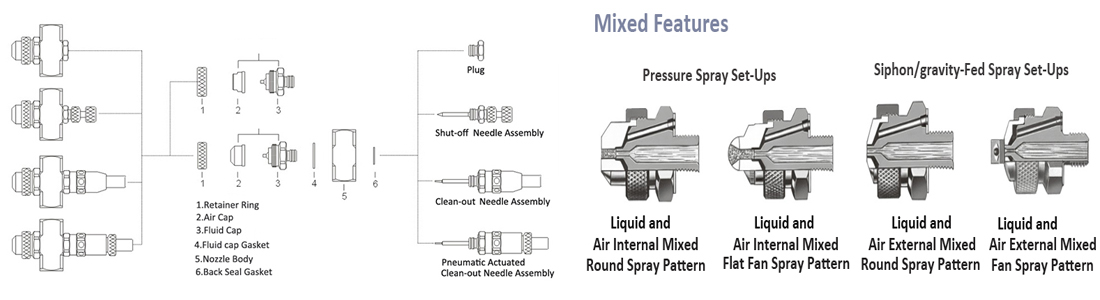

Composition of air atomizing nozzle

Each atomizing nozzle is composed of air cap, liquid cap, reamer, liquid cap gasket nozzle body, rear gasket, needle valve and other components, can provide fan and round spray modes, and has a wide flow range. At the same time, the inlet joint of the nozzle body has a multi-bell size, which can be used conveniently on the multi-bell pipeline.General parameters of air atomizing nozzle

The atomized particles are uniform and small, the average diameter of atomized particles is 50μm, the flow size is adjustable, not blocking, simple maintenance。The spray shape:fan-shaped and cone-shaped

Spray Angle:fan (60°~70°), narrow cone (15°~20°), wide cone (60°~70°)

Atomizing device: mixing inside, mixing outside

Atomization system: pressure atomization, siphon/gravity atomization

Working pressure: 0.7Kg~4Kg

Connection specifications: internal connection or external connection or quick disassembly other

Connection dimensions: 1/8inch, 1/4inch, 1/2inch, and 1inch

Connect noumenon: JAU, J, JN, JCO, JNCO, MN, JBC, JACN, JACT, etc

Application: scenario Humidification, dust removal, cooling, and lubrication

Material composition: stainless steel, other materials of air atomizing nozzles

Classification of air atomizing nozzles

Solid cone wide Angle circular nozzle, fan pressure type air atomizing nozzle (external mixed type), siphon/gravity transmission air atomizing nozzle, automatic air atomizing nozzle, automatic air atomizing nozzle, large flow air atomizing nozzle, etc.

Air atomizing nozzle video demo

Air atomizing nozzle features

1) The use of compressed air and liquid friction, produce very uniform and the finest atomization effect, the average atomized particlesDiameter to less than 50 microns

2) The air atomizing nozzle is composed of a connecting body and a spray device, and the spray device is composed of an air cap and a liquid cap

3) Spray shapes are round, fan and 360 degree ring

4) The connecting body can optionally be equipped with regulating needle valve to regulate the flow

5) The air atomizing nozzle connection body has two independent liquid inlet and air inlet

6) Atomization structure has pressure atomization and siphon atomization

7) The spray device has internal mixing and external mixing

Atomizing effect of air atomizing nozzle

The most important role of air atomizing nozzle is its atomization effect. The atomization effect should be: the spray is symmetrical, the atomization is uniform, the edge is clear, and only a few paint particles can exist outside the spray edge.Under the same conditions, the atomization fineness of air atomizing nozzle decreases with the increase of air hole diameter. When the gas-liquid ratio is 0.4 and the air pressure is 5bar, the atomization fineness is below 10um.

When the air pressure increases from 2bar to 5bar, the atomization particle size decreases from 25um to about 7um. When the air pressure continues to increase and exceeds 5bar, the curve flattens out. At this time, increasing air pressure will not lead to further thinning of atomization.

The atomization fineness of the nozzle decreases with the increase of the number of pores. When the number of pores is more than 6, the decreasing trend of atomization fineness becomes slow. When the number is between 4 and 6, the average particle size is below 10um

Air atomizing nozzle and other common nozzle difference

1) The atomizing nozzle is a fog, and it is a very small fog, but the ordinary nozzle is not as small as the air atomizing nozzle spray effect.2) The work of the air atomizing nozzle is to have the effect of air compressor to spray the fog. Generally, the ordinary nozzle does not need any compressor and is directly connected to the water pipe. As long as the water has a certain pressure, the spray effect can be sprayed.

3) Air atomizing nozzles generally have only fan-shaped and circular spray shapes. The shapes of ordinary nozzles are fan-shaped, solid cone, hollow cone, circular and other bell spray effects.

Air atomizing nozzle refers to double fluid atomization, under the condition of liquid pressure is not too high, through the external gas atomization, atomization effect is good, small particle size can reach dozens of μ, this kind of nozzle and particularly mixed and mixed, mainly nozzle structure, mixing outside can spray some viscous liquid.

Atomizing nozzle is a general name, the liquid can spray into mist are called atomizing nozzle.

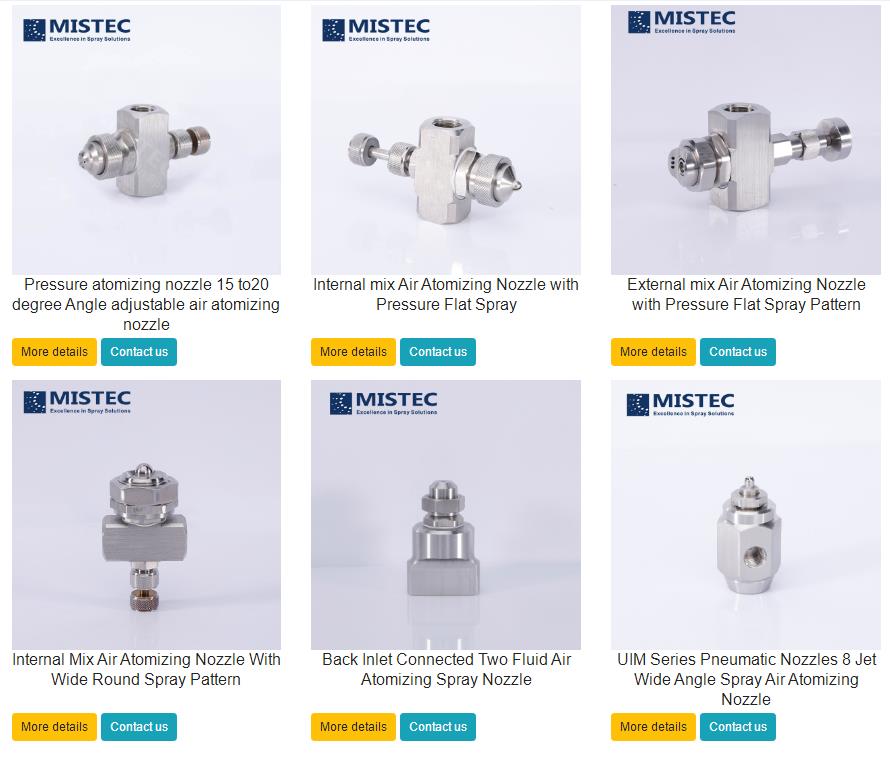

Some air atomzing nozzle show:

For more air atomizing nozzles or atomizing nozzles, click here

If you want to know more about air atomizing nozzle or atomizing nozzle, please contact us.