I. Internal mixing air atomizing nozzle: gas and liquid affect each other, because it is mixed inside the nozzle cavity.

① The liquid pressure is certain, the higher the air pressure, the smaller the liquid flow of the nozzle, the limit is not to spray out, or the gas backpour liquid supply pipeline;

② The liquid pressure is certain, the lower the air pressure, the greater the liquid flow of the nozzle, the attenuation of the atomization effect, the limit is the spray column, because the liquid pressure is small, generally a few kilograms of pressure;

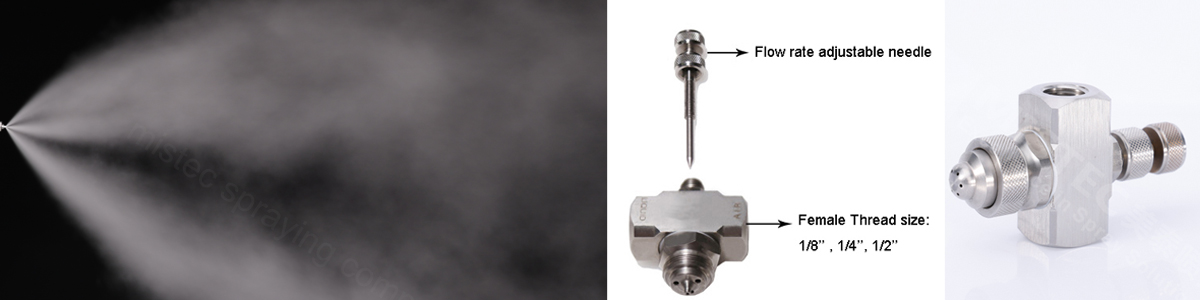

II, External mixing type air atomization nozzle, gas and liquid mixed outside the nozzle, so the liquid flow is not affected by air pressure, the greater the air pressure, the same flow, the better the atomization.

Air atomizing nozzle is to use the principle of compressed air flow at high speed to make liquid particles. The air atomizing nozzle makes the liquid granular in the following three ways:

First, internal hybrid type

Compressed air and liquid are mixed inside the nozzle to make the liquid particulate. In general, it's a superior microparticle method. The internal hybrid is further divided into the following three types:

1. Internal air type

Compressed air forms inside the nozzle at the center while liquid flows around it.

Liquid through the diameter is large, for the type of not blocked by liquid.

2, external gas type

A general pattern in which the liquid is centered inside the nozzle and compressed air flows around it.

Particle size will be larger, but can increase the nozzle opening.

3, premixed type

Low air - water ratio can also accelerate the ejection speed of droplets, so the impact is strong. And can use compressed air to adjust the spray range. Suitable for high temperature area of the object cooling.

Second, external hybrid type

Compressed air and liquid mixed outside the nozzle, generally speaking, is a non-blocking type. External mixed type is also divided into internal and external gas type.

Three, impact type

The microscopized droplets collide with each other to make it homogeneous and microscopized.