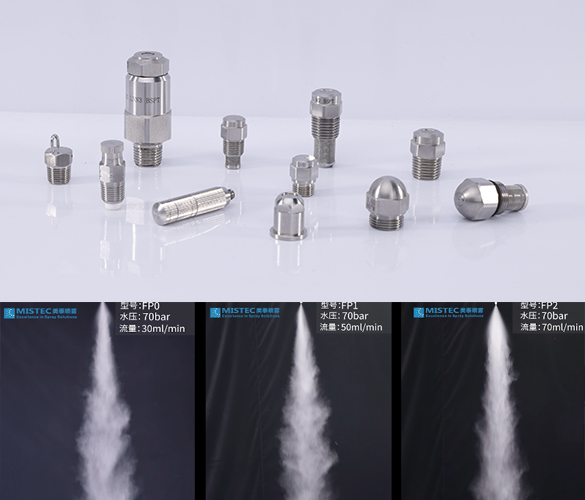

Nozzle structure

Atomizing nozzle is a device that disperses liquid into fine particles, and different nozzle structures will affect the atomization effect. In general, finer atomizing nozzles can produce smaller droplets, so the amount of fog is relatively large. In addition, the diameter and number of the spray hole of the atomizing nozzle will also affect the amount of fog, and the smaller the aperture and the more holes, the greater the amount of fog.Liquid property

The viscosity and surface tension of the liquid are also important factors affecting the amount of fog produced by the atomizing nozzle. The viscous liquid will hinder the spray hole of the atomizing nozzle, thus reducing the fog output; And the surface tension of the larger liquid will make the liquid more difficult to disperse into fine particles, also reduce the amount of fog.

Stress

The outlet pressure of the nozzle is proportional to the fog output, that is, the higher the pressure, the greater the fog output. However, it should be noted that due to the different structure and design of the atomizing nozzle, the maximum working pressure of the nozzle is also limited. Excessive pressure can lead to nozzle failure or even accidents.In summary, the fog output of atomizing nozzle is affected by many factors, including nozzle structure, liquid properties and pressure. When using atomizing nozzles, it is necessary to select suitable nozzles according to specific application scenarios, and carry out reasonable liquid supply and control operations to achieve the best atomizing effect.