The application of atomizing nozzle covers almost all fields. For example, in agricultural production, can be used to spray pesticide disinfection lamp; In the field of fire fighting, can be used to cool the fire; In the field of industrial manufacturing application is more widely, can be used for workshop cooling, humidification, dust removal, spraying, etc. In fact, the shower head commonly used in our home is also an application of liquid atomization technology in real life.

With the deepening of the research, the liquid atomization technology is also continuously enhanced. In addition to the common mechanical atomization, there are also electrostatic atomization, ultrasonic atomization, media atomization and other technologies, small atomization nozzle is also more and more technical content.

Generally speaking, atomization is the liquid through the nozzle, to overcome the surface tension between liquid molecules, with smaller particles separated, so as to produce the effect of atomization. The common mechanical atomization has direct shot nozzle, pressure nozzle and rotary atomization nozzle.

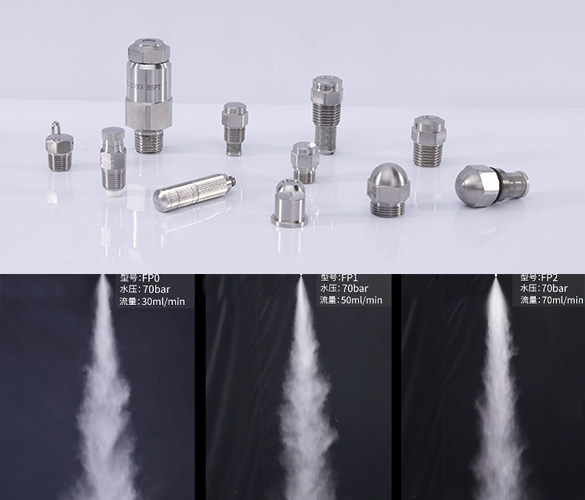

The working principle of the pressure atomizing nozzle is that when the liquid is sprayed out of the nozzle at a high speed under the action of high pressure and enters into the static or low-speed air flow, the atomization process is different due to the different flow channel structure inside the nozzle. Like liquid column flow nozzle is direct nozzle; Hollow cone, solid cone, fan nozzle, spiral nozzle and so on are pressure nozzle.

Rotating atomizing nozzle is to supply liquid to the center of high-speed rotating parts driven by motor (and pneumatic), and the liquid is thrown out to the surrounding parts or holes of the rotating parts, so as to produce atomization effect with the help of centrifugal force and gas power. When the liquid flow rate is small and the centrifugal force is greater than the surface tension of the liquid, a small number of large droplets thrown from the edge of the turntable will directly split into droplets at this time. When the flow rate and rotational speed increase, the liquid is pulled into a large number of filamentous jets, the liquid flow is extremely unstable, after leaving a certain distance from the disk edge, the liquid is separated into small droplets due to friction with the surrounding air. When the speed and flow rate increase again, the liquid wire is connected into a thin film, as the liquid film expands outward into a thinner liquid film, and at a high speed and the surrounding air friction and separation atomization, the film is split into droplets. The atomization effect of rotary atomizer is better, the atomization flow of single equipment is large, and it is widely used in spray drying, desulfurization, waste incineration tail gas treatment.

Medium atomization is to use the velocity difference between the liquid at low speed and the gas at high speed to tear the liquid and achieve the atomization effect. According to different working media medium atomization can be divided into steam atomization and air atomization.