How can industrial humidification system be used in aseptic production line of health care products

The aseptic production line of nursing products has strict requirements on humidity, dust concentration, static electricity and so on. Without scientific control measures, it is difficult for the production line to meet the required requirements. For this reason, some aseptic production lines of nursing products began to install the industrial humidification system of dry fog humidifier, using fine water mist humidification, dust removal, static electricity.

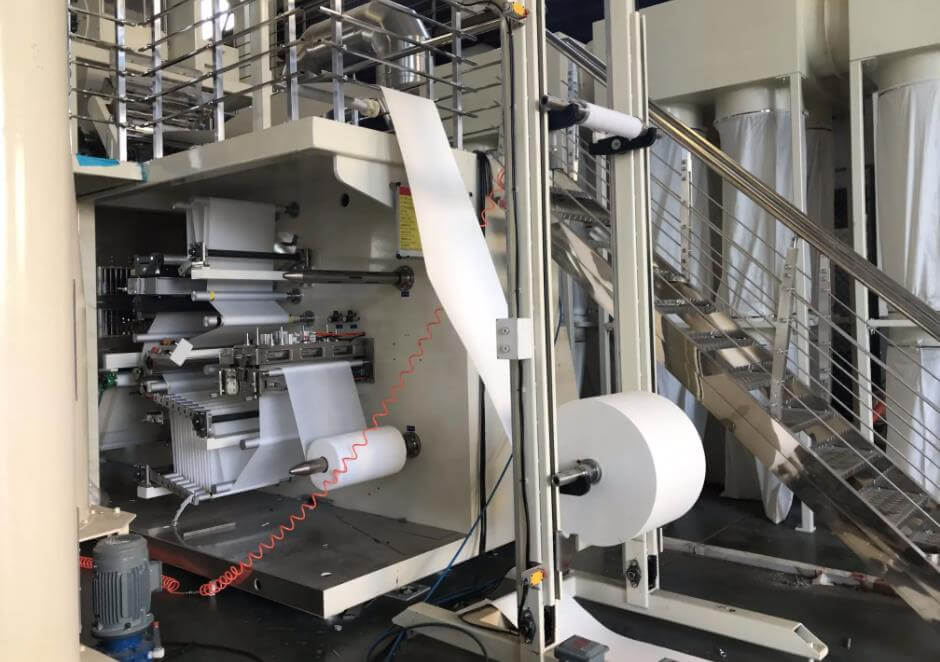

First, aseptic production line humidifier box introduction

Nursing enterprise is a leading enterprise in the diaper industry, focusing on the research of adult, infant, elderly and other FMCG care products. The company's automatic production line is equipped with dry fog humidifier, which can greatly improve the qualified rate of products, reduce the probability of contamination of nursing products in the production process, ensure the health and safety of products in the production process, and increase the quality and stability of products.

Two, Atomizing humidification equipment requirements for aseptic production line

The aseptic production line of nursing products needs to eliminate particles, harmful air, bacteria and other pollutants in the air in a certain space. By humidifying and drying the fog, the ejected dry fog particles contact with the air to exchange dry and wet, so as to achieve the purpose of humidifying and dedusting the air. The humidity in the air is controlled between 45%-60%RH, and no dripping condensation can occur.

Three, Aseptic production line atomizing humidification solution

Workshop industrial humidifier system manufacturers calculate the humidification amount by calculating the area, the height, the initial humidity value, the target humidity value, the tightness, the wet source, the fresh air volume and other comprehensive factors. And select a humidifier. Specially designed and installed a set of dry fog humidifier scheme. A total of 34 JS-GW-4 dry fog humidifiers were installed. The air consumption of a single humidifier is 0.2m /min and the water consumption is 10kg/h. Five sets of 2-way control boxes and three sets of 1-way control boxes are installed according to different production lines.

Four, Introduction to aseptic production line atomizing humidification products

The dry fog humidifier adopts the principle of siphon atomization system. The separated compressed gas and liquid meet at the special stainless steel nozzle, which can realize the two-stage atomization to obtain the best spray effect. The diameter of spray particles is 5-7μm. The water supply is determined by the proportional control device in the controller, by which the spraying effect can be changed.

Five, The advantage of humidification products in aseptic production line

The industrial humidification system of dry fog humidifier adopts the design of vacuum valve and the mixed design of air and water to induce humidification through the negative pressure of compressed air. Choose the automatic control system of humidifier, can realize the effective humidification in different stages. The intelligent temperature and humidity control system can display the humidity in the humidification area, realizing automatic and constant humidity operation within 3%RH. Under the same water supply conditions, the higher the air supply pressure, the better the atomization effect, the finer the atomization particles. Dry fog humidifier can automatically adjust the mixing ratio of air and water, so that the spray of dry fog is always in the best condition. Multiple safety protection devices are used to ensure that the nozzle does not drip or spray water. The humidification efficiency is high, the droplet diameter is small, the atomization effect is guaranteed, the nozzle is not easy to jam, and the maintenance workload is less. These good performance advantages make the dry fog humidifier can be used in different conditions to complete the humidification task well!

Six, Humidification acceptance of aseptic production line

After the dry fog humidifier is installed in the workshop, the spray of water quickly covers the whole workshop after debugging, and the humidification and dust suppression effect is obvious. And the mist particles are small, will not wet the workshop equipment and products. Workshop overall humidity up, stable control in a certain value, workshop production is very beneficial.

Environmental humidity of production line will directly affect product quality. An overly dry environment in the workshop is not only detrimental to production, but also affects human health and comfort. As a convenient way of humidification, dry fog humidifier plays an increasingly important role in industrial production and is also widely used by manufacturers. If you also have workshop humidification needs, you can call us.