What is the air atomization system

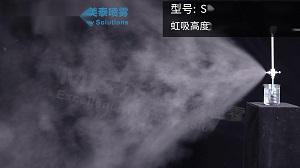

Air atomization system is a kind of equipment that converts liquid into tiny droplets, which is often used in humidification, cooling, spraying and other fields. The core principle is to use compressed air to break the liquid into fine particles to form a fog.

Major component

Liquid supply system: Store and transport liquids to be atomized.Compressed air system: provides high-speed airflow for atomizing liquids.

atomizing nozzle: Liquid and compressed air are mixed and atomized here.

Control system: Adjust the flow and pressure of liquid and air.

Working principle

When compressed air passes through the nozzle, high-speed air flow is generated, and the liquid is broken into tiny droplets under the action of the air flow, forming a fog.

Application field

Industrial humidification: used for humidity control in textile, printing and other industries.Cooling: Used for cooling in greenhouses, data centers and other places.

Spraying: Used for surface coating, such as automobile painting.

Agriculture: Used for pesticide spraying and greenhouse humidification.

Medical treatment: Used for atomizing drugs to treat respiratory diseases.

The spray requirements of atomization systems usually include the following aspects:

Atomized particle size:

Particle size range: According to the application requirements, the atomized particle size is usually between 10-100 microns. For example, medical nebulizers require a particle size of 1-5 microns, while agricultural sprays may require 50-150 microns.Particle size distribution: uniform particle size distribution is required to avoid the effect of too large or too small particles.

Spray volume:

Flow control: The amount of spray needs to be precisely controlled to ensure that the amount of liquid output per unit time meets the requirements.Adjustable: The system should have a flow adjustment function to adapt to different needs.

Spray uniformity:

Coverage: The spray should evenly cover the target area to avoid local excess or deficiency.Consistency: The spray density should be consistent throughout the area.

Spray Angle and direction:

Angle control: The spray Angle needs to be adjusted according to the application, such as a narrow Angle for directional spraying and a wide Angle for large area coverage.Direction control: The spray direction should be adjustable to ensure accurate coverage of the target.

Atomization efficiency:

Droplet utilization: minimize droplet dispersion and waste, improve utilization.Energy consumption: Reduce energy consumption under the premise of ensuring the effect.

.jpg)

Spray stability:

Continuous stability: The system should be able to maintain stable spray performance over a long period of time.Anti-interference: Under environmental changes (such as temperature, humidity), the spray performance should remain stable.

Cleaning and maintenance:

Easy cleaning: The system should be easy to clean and prevent clogging and contamination.Easy maintenance: Maintenance operations should be simple to reduce downtime.

Security:

Material safety: Materials in contact with liquids should be non-toxic and corrosion-resistant.Operation safety: The system should have the necessary safety protection measures, such as overload protection, anti-leakage, etc.

Environmental adaptability:

Temperature range: The system should be able to work properly in a wide temperature range.Humidity adaptability: In high humidity or low humidity environments, spray performance should not be affected.

Noise control:

Low noise: The system should be operated with as little noise as possible, especially in medical and indoor applications.

These requirements vary according to the specific application, and the design and use need to be adjusted according to the actual needs.