Nozzle atomization technology has a wide range of applications, mainly for liquid fuel atomization, from its atomization mechanism, atomization method, liquid fog testing technology and combustion

The numerical simulation technology of oil atomization is briefly explained.

1 Introduction

Atomization technology has covered almost all industrial fields, such as transportation, agricultural production, and People's Daily life, in addition to the combustion of various fuels (gas, liquid and solid fuels), atomization technology in non-combustion workers

Industries such as catalytic granulation, food processing, powder coating, pesticide spraying also have a wide range of applications. In this paper, the atomization technology of liquid fuel is briefly introduced.

The so-called liquid atomization refers to the physical process in which the liquid becomes liquid mist or other small droplets in the gas environment under the action of external energy. For its atomization mechanism, there have been many explanations, such as aerodynamic disturbance, pressure oscillation, turbulence disturbance, air disturbance, abrupt boundary conditions, etc., are briefly introduced as follows: 1~3.

2.1 Aerodynamic interference theory

According to the theory of aerodynamic interference, the surface of the jet is unstable due to the aerodynamic interference between the jet and the surrounding gas. As the velocity increases, the surface length of the unstable wave becomes shorter and shorter until the jet is in the order of micron (m), and the jet is dispersed into a mist.

2.2 Pressure oscillation

It is observed that the pressure oscillation of the liquid supply system has a certain effect on the atomization process. Therefore, according to the common pressure oscillation in the general injection system, it is considered that it plays an important role in atomization.

2.3 Turbulence theory

The turbulence theory holds that the process of jet atomization occurs inside the nozzle, and the turbulence of the fluid itself may play an important role. It is also believed that the radial velocity of the fluid in the nozzle, which is a turbulent tube flow, will cause immediate disturbance at the nozzle exit, resulting in atomization.

2.4 Said air disturbance

The air disturbance theory holds the opposite attitude to the turbulent disturbance theory, and holds that the large amplitude pressure disturbance caused by cavitation in the oil injection system is the cause of atomization.

2.5 Sudden change of boundary conditions

The abrupt boundary condition theory holds that the fluid's boundary condition (internal stress) changes abruptly at the nozzle exit. Or the laminar jet protrudes and loses the nozzle wall constraint, which causes the velocity distribution in the section to change abruptly and produce atomization.

The five nozzle mechanism hypotheses listed above all have shortcomings and even contradict each other. Most scholars, such as Bracco F V et al. 1~2, support the aerodynamic interference theory. This hypothesis is well developed

The reason of the splitting and breaking of the low speed jet is explained, and it is deduced that the high speed jet can be used as the basic reason of atomization. At present, the research of fuel injection atomization mechanism at home and abroad is mainly carried out from two aspects: First, the use of numerical computing technology to establish a variety of hypothesis models for numerical modeling research 4~6; On the other hand, advanced photoelectric testing technology is used to capture the details of the atomization process in order to provide support for a certain or comprehensive hypothesis.

3. Atomization process and method

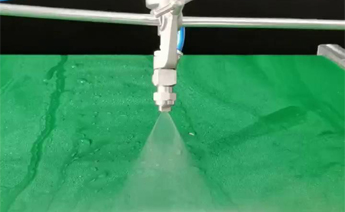

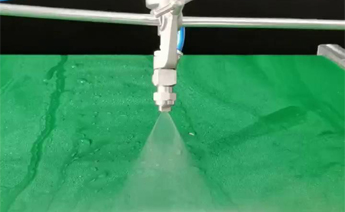

Through atomization, the liquid fuel forms a liquid fog with small particles and uniform size to increase the contact area between the liquid fuel and the combustion air, promote evaporation, so that the fuel can be fully and effectively burned. And the finer the atomization, the fuller the combustion. Usually, the spray atomization process of liquid fog is divided into three stages: first, the liquid flows inside the nozzle; The second is the phase in which the liquid column splits into droplets after the liquid is ejected. The third is the further crushing stage of the droplets in the gas. The second stage is the main one, which can be explained by the aerodynamic interference theory. There are a variety of liquid atomization methods, which are mainly representative of mechanical atomization, medium atomization, and special nozzle atomization.

Special nozzle atomization

Special nozzles are generally atomized by ultrasonic wave, electromagnetic field, electrostatic action and other principles. Ultrasonic atomization is also known as ultrasonic oscillation atomization, its atomization mechanism is more complex, relevant people believe that the principle of ultrasonic atomization is: Ultrasonic air flow into the resonator to produce high frequency pressure wave, the wave transmitted to the liquid surface causes vibration to produce ultrasonic wave, the peak caused by vibration amplitude separates and breaks the liquid droplet from the surface, with the increase of ultrasonic frequency atomized droplets become finer and finer, generally under the action of ultrasonic vibration frequency can obtain a few microns of fuel droplets 10. Because the atomization performance of ultrasonic is generally better than other atomization methods, its atomization drop diameter is small (below 100 m), the uniformity of fog drops is also better, and the size distribution uniformity index is 2, so it is easy to achieve low-oxygen combustion, thereby reducing the emission of nitrogen and oxygen pollutants in the flue gas. Electrostatic atomization is mainly used in paint atomization. In electrostatic spraying, due to the action of high voltage electrostatic field, the paint droplets will be split into fine particles, so that the paint can be atomized. Electrostatic atomization is always used in combination with other atomization methods in paint atomization equipment.