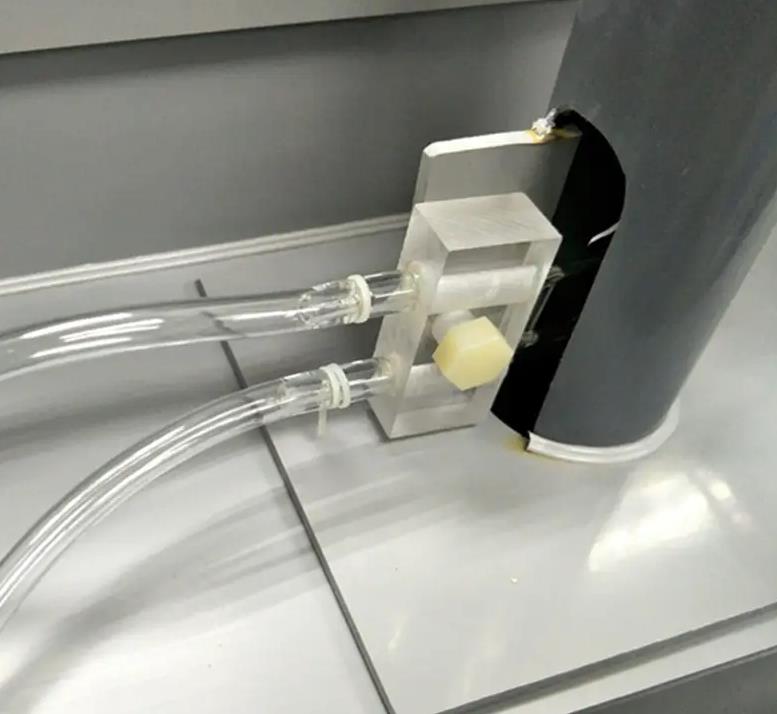

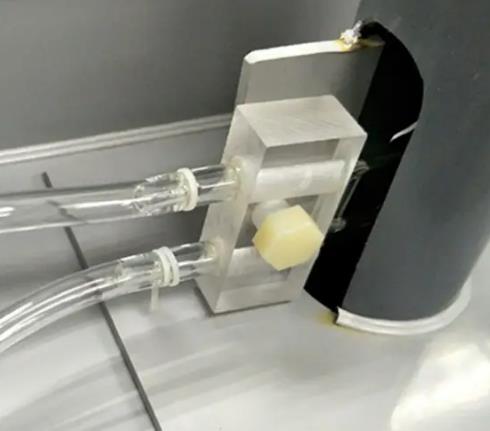

Salt spray corrosion tests require a salt spray test chamber to produce salt spray. The key is that under a certain pressure of compressed air, the test solution is sprayed through the nozzle. The quality of the nozzle directly affects the success of the test. When the nozzle is manufactured, the aperture and bending Angle of the nozzle should be strictly controlled to ensure that the standard salt spray can be produced. In practical applications, the nozzle is often blocked and damaged, which affects the normal test.

In order to better protect the nozzle of the salt spray test chamber, share some tips for you:

1. Use distilled water or deionized water to reduce impurities in the water and reduce the chance of nozzle blockage.

2, install the oil-water separator to avoid the introduction of water vapor and oil when compressed air, so that the oil adheres to the nozzle wall. Due to the small aperture of the nozzle, the impurities in the water and the adhering oil will affect the formation of the salt spray.

3, in order to avoid impact, when installing the nozzle or dredging the blocked nozzle, you should pay attention to handling gently, do not use too much force to break the nozzle.

4, the injection pressure setting should not be too large. Under normal circumstances, the pressure is between 0.07mpa and 0.17mpa. If the pressure is too high, the nozzle will break.

These are some of the daily protection measures of the nozzle. During the test, if the spray amount is too large/too small or does not spray, the nozzle should be checked to see if it is normal. If the nozzle aperture is too large, it should be replaced. If it is blocked, apply a thin wire gently through it to unclog the nozzle.