(1) In order to carry out large-area cleaning, the spray gun can make the high pressure nozzle arranged on the cylindrical end face, and can also place the fan high pressure nozzle on a straight pipe in turn, so that the multi-end jet occurs and the cleaning equipment increases the coverage area of the cleaning.

(2) Balanced spray gun, which is a backless spray gun, very suitable for high elevation cleaning operations.

(3) Long spray gun, high pressure cleaning machine, its structure is relatively large, in addition to the general rigid long spray gun, the high pressure nozzle fixed internal longitude is 4.8-25.4 meters of flexible spray rod or rigid spray rod can also be used in conjunction with the spray gun.

(4) Short spray gun, clear, its structure is small and exquisite, according to different cleaning objects, arbitrary control into the required jet, this spray gun can spray three kinds of jets according to the size of the impact force, they are; Soft fog, hard fog and impact water column. The range of the soft fog jet can reach half a meter within the planning, its impact force is somewhat slender, suitable for cleaning objects and glass with less pressure, but the useful range of the impact water column can reach 12 meters, the impact is very strong, and can be used to clean the appearance of hard adhesion dirt. The range of the hard object jet can be scheduled between half a meter and 12 meters according to demand, and can be used to clean the shell of a car and the exterior of a building, as well as other objects that can accept a certain pressure.

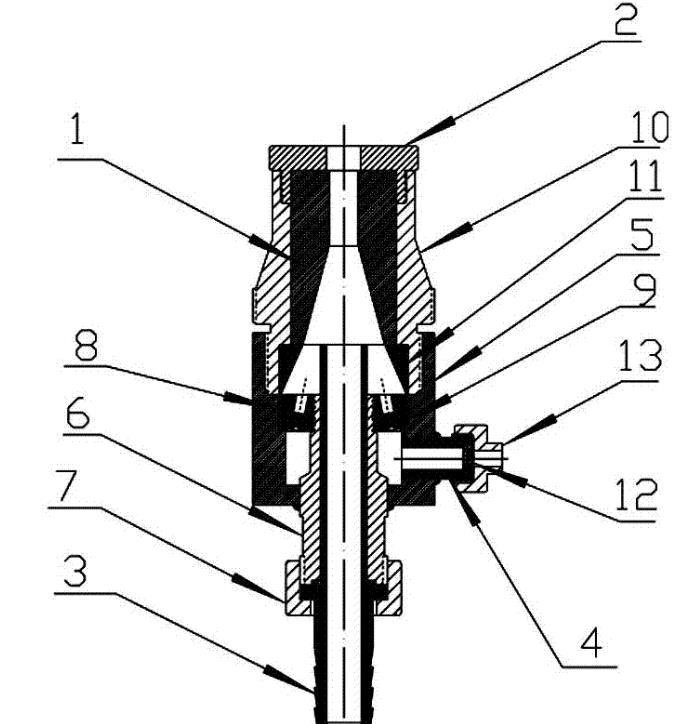

The high pressure spray gun is the actuator of the high pressure cleaning machine and an important part of the high pressure cleaning machine. The spray gun includes two parts: a control valve (two-position two-way) and a high pressure nozzle. When high pressure water enters the spray gun, it enters the back cavity of the spool through the middle orifice of the relief valve spool, which is the pilot valve cavity. The high pressure reflux strengthens the sealing pressure of the spring force on the spool of the relief valve. When the pilot valve building force is reduced, the high pressure water will open the pilot valve and return to the low pressure chamber for unloading. At the same time, the relief valve will open due to the loss of back pressure. Basically, all the high pressure water will overflow through this channel, and the pump will run without load. On the contrary, when the spring force of the pilot valve is increased, the back pressure of the relief valve is re-established to ensure that the valve is closed, and the high pressure water is directly to the high pressure nozzle to form a jet.

The pressure loss caused by the flow of high pressure water in the high pressure spray gun is very large, and the maximum pressure loss can account for 60% of the total pressure loss of the high pressure washer. High pressure spray gun is mainly composed of high pressure nozzle, high pressure nozzle and hand-held spray gun several parts, they are the direct working mechanism of high pressure cleaning machine. The high pressure nozzle is the core component that directly converts the pressure energy of high pressure water into the speed energy of crushing scale, and its performance and quality determine the cleaning efficiency of high pressure cleaning machine. Therefore, the quality of the spray gun is the most important issue of the high pressure washer. Its design should follow the following three principles:

1, ensure that the high pressure pump in the rated pressure, flow and power conditions.

2, high pressure nozzle hole design to ensure high pressure water jet with high density, bunching and strike efficiency.

3, the high pressure nozzle should have high processing accuracy and long service life.