Oil atomizing nozzles are widely used in diesel oil. Heavy oil, residual oil. Alcohol-based fuel. Tire oil, bio-oil and other fuel gas incineration fog spray system, workshop humidification and cooling, machine parts cleaning and dust removal. Various types of industrial spray products. Mistec spray planning manufacturer, producing a full range of fuel nozzles. Siphon type nozzle. Pile-type nozzle. Atomizing and humidifying nozzle. Cleaning nozzles, etc.

The advantages of the bubble atomization method are low air consumption, high atomization quality, and atomization effect is not affected by the outlet diameter. Therefore, bubble atomization is more suitable for atomizing heavy, residual oil and other high-viscosity liquid fuels. The principle of bubble atomization is to inject compressed air into the liquid, and make both of them form a stable bubble-like two-phase activity in the mixing chamber of the atomizing nozzle, and make drastic changes at the very short interval from the outlet of the atomizing nozzle to promote its rapid expansion until it is split, and further break the liquid film wrapped around it into a more delicate liquid fog particles.

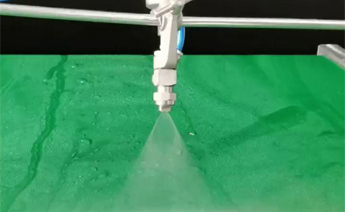

Pneumatic atomization is able to achieve excellent atomization effect under low fuel supply pressure, and can also achieve high atomization quality when using high-viscosity fuel, and can be scheduled in a wide range and use active network. The principle of pneumatic atomization is to rely on a certain pressure of gas to form a high-speed airflow, and then promote a high relative speed between the gas and the fuel to reach the purpose of atomization.

The atomization of the atomizing nozzle can turn the liquid fuel into a very fine particle, a standard uniform liquid fog to add the touch area between the liquid fuel and the combustion air, which can be useful to promote transpiration, and then make the fuel fully and effectively incinerated, and the finer the atomized particles are incinerated, the more abundant. Therefore, the choice of excellent atomizing nozzle is an important way to save energy in the process of production power.