General knowledge of nozzle selection in coating and spraying system

2. Characteristics of nozzle

Because the nozzle is designed according to its work in a variety of different spray conditions, so choose a suitable nozzle, in order to achieve the best spray performance in use.The characteristics of the nozzle are mainly reflected in the spray type of the nozzle, that is, the shape formed when the liquid leaves the nozzle mouth and its operating performance. Nozzles are named for the shape of spray, which can be divided into fan-shaped, conical, liquid column flow (i.e. jet), air atomization and flat nozzles. Conical nozzles are divided into two categories: hollow cone and solid cone. The Venturi nozzle (i.e. mixing nozzle), strong cold (hot) air nozzle and special nozzle (such as garden nozzle, cylinder washing nozzle, pipe cleaning nozzle, etc.) the naming reflects the running performance of the nozzle.

3. Select the elements of the nozzle

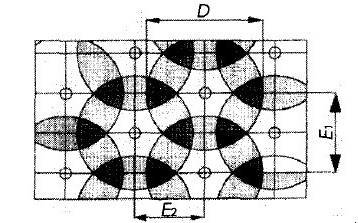

Generally speaking, the nozzle of degreasing and washing process can choose the jet nozzle with strong impact force. Take the "V" type nozzle, namely the fan type nozzle, for example, the jet Angle of 60° is the best, which has a large impact force; The phosphatizing process of the nozzle can choose good atomization, water particles fine and uniform, the impact force is weak centrifugal nozzle: "Z" type conical nozzle as an example, the best distance from the nozzle to the workpiece is 40cm ~ 50cm, with dispersion, the liquid atomization spray effect. The arrangement of nozzles on the nozzle can adopt two forms of parallel and cross, and the vertical cross arrangement is adopted for the passage, so the spray effect is better.The factors that choose nozzle include flow rate, pressure, spray Angle, coverage area, impact force, temperature, material, application, etc., and these factors are often associated with each other and mutually restricted. Flow and pressure, spray Angle and coverage are proportional. The purpose of any nozzle injection is to maintain continuous contact between the tank and the workpiece. This factor is more important than pressure. The temperature of the liquid does not affect the spray performance of the nozzle, but it affects the viscosity and specific gravity, as well as the choice of materials. The material of the nozzle should also be determined according to the chemical characteristics of the tank, and the non-corrosive tank can be cast in bronze or plastic according to the difficulty of processing. In order to prevent corrosion, non-metallic materials can be used; For sulfuric acid, hydrochloric acid and other strong corrosion tank, nylon plastic can be used; The nozzle material for phosphating tank is generally made of acid-resistant stainless steel, and the nozzle to prevent corrosion can also be directly made of stainless steel or nylon.

The nozzle with a certain impact force should be selected as a small Angle nozzle, with the liquid column flow (namely jet) as the best; Fan nozzle is suitable for cleaning, degreasing, cooling and other aspects, conical nozzle is suitable for bleaching, surface, phosphating, humidification, dust removal and other aspects; Venturi mixing nozzle should be installed in the paint storage tank and tank body. Taking the "H" type mixing nozzle (also known as Venturi nozzle) as an example, the tank is mixed with the liquid sucked into the inlet at a flow rate of 1:4 after a certain pressure, and then diffused and sprayed out, so as to achieve the effect of air-free mixing and stirring of the solute, thus preventing precipitation, because the agitation ensures the uniform mixing of the chemical solution.

4. Layout of nozzle

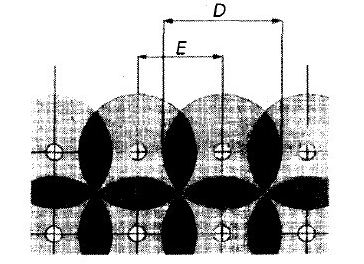

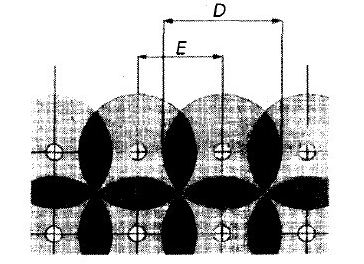

A number of nozzles are installed in a certain arrangement on the annular pipe formed according to the outline size of the workpiece to surround the workpiece, so that when the workpiece passes through the spray area, all the surface can be sprayed by the tank. The whole spray area should be evenly arranged nozzles to ensure the process time and effect of the spray. The distance between the nozzle and the workpiece should be within the optimal diffusion range of the jet, so the nozzle and nozzle arrangement should be reasonable. The distance between the nozzle and the nozzle is 250mm ~ 300mm, when the cross arrangement, the distance between the nozzle and the workpiece is not less than 250mm.

A complete tank injection system is formed from the pump to the pipeline to the mixing nozzle. The stirring nozzle applies Venturi principle. The tank enters the pipeline under a certain pressure, forms a high-speed jet through the nozzle hole of the stirring nozzle, and generates a low pressure area around the nozzle inlet, forming a siphon phenomenon. Under the action of pressure difference, the tank is sucked into the stirring nozzle, so that a large amount of liquid can be circulated. The distance between the stirring nozzle and the bottom of the groove is 25mm ~ 75mm, and the distance between the stirring nozzle and the workpiece is 200mm ~ 380mm. The Angle of the spray hole should be determined according to the size of the workpiece. When the width of the workpiece is small, the spray hole can be designed vertically upward, when the workpiece is large, the spray hole can be designed with the vertical plane into 35° ~ 45°; When the width of the workpiece is large, in order to improve the mixing effect, the spray hole can be designed vertically downwards, but this situation will stir up the sediment, so it is only suitable for the agitation of non-sediment tank.

5, the quality of the nozzle inspection and the common causes of damage

Nozzles need to be repaired, inspected, cleaned and even replaced regularly in order to ensure the quality of the final product and maintain the economic efficiency of the production process. The manner and frequency of maintenance procedures depends on the use. The maintenance schedule can be arranged according to the use, liquid and nozzle material.There are seven common causes of nozzle spray problems:

a) Corrosion and wear: the material on the surface of the nozzle nozzle and internal flow passage gradually becomes larger or deformed, which affects the flow rate, pressure and spray shape.

b) Corrosion: corrosion caused by spray liquid or environmental chemical action destroys the nozzle material.

c) Blockage: dirt or other impurities in the liquid block the nozzle mouth, thus limiting the nozzle flow and interfering with the spray shape and its uniformity.

d) Bonding: splash, mist or chemical accumulation caused by liquid evaporation on the material inside or outside the nozzle nozzle edge, which can leave a dry solidified layer and block the nozzle nozzle or internal flow channel.

e) Temperature damage: overheating will have certain damaging effects on nozzle materials designed for non-high temperature purposes.

f) Incorrect installation: off-axis gaskets, excessive tightening or other positional changes can have adverse effects.

g) Accidental damage: During installation and cleaning, the nozzle may be accidentally damaged due to the use of incorrect tools.

6. Application field of nozzle

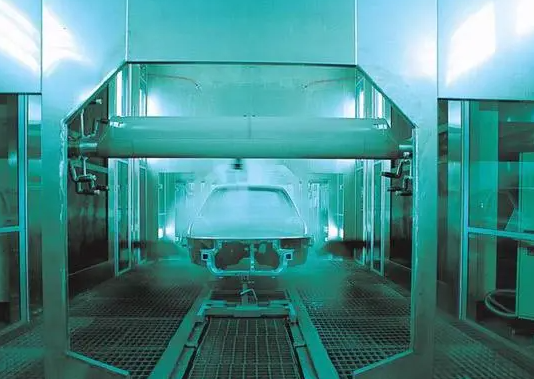

1. All kinds of cleaning machines in the automobile manufacturing industry, spray cleaning in the coating line, atomization spray, tank mixing and other equipment.2.Motorcycle, bicycle, refrigerator, washing machine and other manufacturing industries in all kinds of cleaning machines, coating lines.

3. Various cleaning equipment in the mechanical processing industry.

4. Humidification device in light textile industry.

5. Cleaning machine factory, coating equipment factory supporting nozzle.

6. Nozzle for agricultural sprinkler irrigation and urban greening.