Spray nozzle microhole machining is a kind of microhole machining technology for the surface of small and medium-sized parts, which has the characteristics of fine size, depth and thickness can be processed, and the accuracy can reach the micron order. It is widely used and can effectively enhance the performance and quality of parts.

.jpg)

Spray nozzle microhole machining has a variety of processes, such as it can be realized by electronic flame, laser and internal combustion engine processing, and the accuracy of the surface spray nozzle machining of small parts can reach the millimeter level, which can meet the requirements of the workpiece surface delicate level.

In addition, spray nozzle microhole processing also has diversity, it can achieve more complex micrographics processing technology, such as processing polygons, multi-angle transition of micrographics and so on. In order to achieve the purpose of improving the quality of parts, it is used in aerospace, medical, automotive, industrial automation and other electronic products industry.

.jpg)

First, the production process of spray nozzle

1. Selection of spray nozzle materialsThe material of the spray nozzle needs to have high temperature corrosion resistance and wear resistance. Common spray nozzle materials are stainless steel, tungsten steel, ceramics and engineering plastics. Among them, the stainless steel spray nozzle is better when the corrosion is not strong and the temperature is not high, and the tungsten steel spray nozzle can withstand higher temperature and corrosion. Ceramic spray nozzles can be used in high temperature, highly corrosive environments, but the manufacturing cost is higher. Engineering plastic spray nozzle is relatively low price, suitable for some do not need high temperature and high pressure spraying.

2. spray nozzle manufacturing process

The manufacturing process of spray nozzle generally includes precision machining, grinding and testing. In the early stage, it is necessary to use CNC machining equipment to process the spray nozzle to ensure that its geometry and surface roughness meet the requirements. After the processing is completed, it is necessary to grind the surface smoothness and flatness to meet the specified standards. Finally, quality inspection is carried out to ensure that the spray nozzle produced has stable performance and reliable quality.

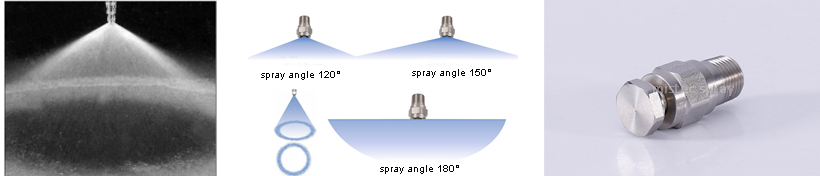

Second, the use of common spray nozzles

1. Atomizing spray nozzleAtomizing spray nozzles are mainly used in coating, spray painting and powder spraying industries. The spray nozzle is small, which can produce high precision atomization effect, so that the coating is uniform and fine. It is necessary to select the appropriate spray nozzle according to the viscosity and flow rate of the coating.

2. Flame spray nozzle

Flame spray nozzles are widely used in the fields of metal product heating, cutting and welding. The flame emitted by the gas mixture can generate high temperatures for efficient thermal processing. Pay attention to safety when using, to avoid burns and other dangerous situations.

3. Foam spray nozzle

Foam spray nozzles are mainly used in the field of fire rescue, which can quickly produce foam and extinguish fires. In use, different types of foam spray nozzles need to be selected according to the specific situation.

Three, spray nozzle maintenance

1. Wash regularlyThe spray nozzle will be blocked or scaled after use for a period of time, affecting its use effect, so it needs to be cleaned regularly. When cleaning, special cleaning agent or acid and alkali solution can be used to clean the blocked substance.

2. Avoid bumping or falling

The spray nozzle needs to be handled gently to avoid bumping or dropping. After use, it should be stored in time to avoid contact with other items and avoid wear or damage.

.jpg)

Conclusion

This paper introduces the production process of spray nozzle, including material selection and machining, grinding and testing in the manufacturing process. At the same time, it also introduces the use of common spray nozzles and maintenance knowledge to help everyone better understand the production and use of spray nozzles. Whether in paint, metal processing or fire rescue, the spray nozzle plays an important role in the work needs to pay attention to safety, and in accordance with the use and maintenance requirements of the correct use and maintenance.

In short, spray nozzle machining microholes can not only ensure the surface size of the workpiece is delicate, but also achieve complex and diverse processing technology to meet customers' requirements for quality, quality, performance and appearance, so that spray nozzle machining microholes have a wide range of applications and far-reaching influence in various industries.