First, the structure of the high-pressure sprayer nozzle overview

The nozzle of a high pressure watering sprayer is mainly composed of a nozzle, a throttling device and a ring gap. Generally divided into fixed nozzle and rotary nozzle two structures. Fixed nozzle refers to a fixed nozzle, high-pressure water flow in the nozzle through the nozzle generated by the throttling device to form a high-speed jet; Rotary nozzle means that the nozzle is fixed on a rotating shaft, and the rotating spray is generated when it is rotated.

Second, the structural characteristics of the fixed nozzle

The fixed nozzle is mainly composed of a nozzle, a throttling device and a ring gap. The nozzle is a symmetrical guide cone through which the direction and velocity of the high-pressure water flow are controlled. The throttling device is a nozzle composed of a group of water inlet and outlet located in the guide cone, through which the flow rate and injection direction of high-pressure water can be controlled. The gap ring is a ring gap located inside the nozzle, which controls the spray range and the size of the spray through the adjustment of the gap.The fixed nozzle has the advantages of simple structure, easy maintenance and low cost, but its spray range and spray Angle are fixed and cannot be adjusted at will. Therefore, it is suitable for some regular cleaning, such as fixed ground cleaning and surface cleaning.

Third, the structural characteristics of the rotary nozzle

The rotary nozzle is mainly composed of a nozzle, an inlet and outlet and a fixed rotating shaft. Inside, there is a set of blades through which water flows to form a rotating high-speed stream, which creates a rotating spray. At the same time, the inlet and outlet of the water can be adjusted to control the flow rate and direction of the jet water, and the rotation Angle can be controlled by the fixed rotating shaft.The structure of the rotary nozzle is relatively complex and the cost is high, but the spray range and spray Angle can be adjusted at will, and the application range is wider. It is often used for cleaning irregular shapes, such as internal cleaning of pipelines.

Fourth, the internal structure principle and spray mode of the nozzle

The nozzle head part inside the nozzle of the high-pressure sprayer is mainly composed of a throttling device, whose main function is to reduce the cross-sectional area of the high-pressure water flow, so as to improve the spray speed and pressure of the nozzle. At the same time, the shape design of the throttling device can affect the spray Angle and spray pattern of the water flow.When the cross-sectional area of the nozzle head decreases, the velocity and pressure of the water flow will increase, and the higher water kinetic energy will be generated. The water kinetic energy is transferred to the jet through the pressure generated by the annular gap, resulting in a high-speed jet.

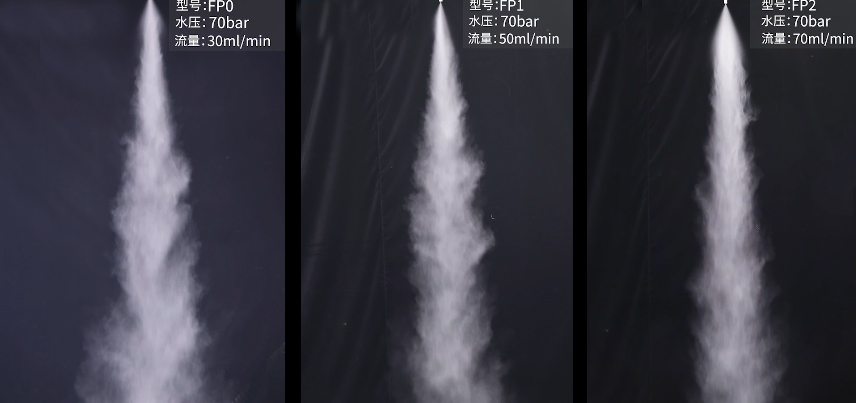

The size, shape and position of the throttling device and gap ring inside the nozzle will affect the spray mode of the nozzle. When passing through the gap, the high-pressure water flow forms the central axial flow and the dispersion boundary layer respectively. The central axial flow is divided into fast flow zone and slow flow zone. The fast flow zone is in the center of the jet and the injection speed is faster, whereas the slow flow zone is in the edge of the jet and the injection speed is slower. At the same time, due to the existence of annular gaps, the flow rate of the jet will slow down, thus forming a dispersion boundary layer. The size and shape of the gap ring can adjust the thickness of the dispersion boundary layer and the spray range.

Five. Use precautions

1. Protective goggles and gloves must be worn during the use of the high-pressure sprayer nozzle to avoid the impact of high-pressure water.2. When removing the nozzle, the high-pressure water source must be closed and the internal pressure of the nozzle can be released before operation.

3. The nozzle can not maintain the same position for a long time during use, otherwise the inside of the nozzle will be overheated and damaged.

4. The nozzle needs to be cleaned regularly to ensure the spray quality and effect.