In the construction of water-based industrial coatings, one of the most important coating methods is spraying. Today, what I want to share with you is the relevant content of mixed gas spraying.

Mixed gas spraying, also known as air-assisted airless spraying, concentrates the advantages of airless spraying and air spraying, on the one hand, it can spray high-viscosity paint and obtain thicker paint film, on the other hand, like air spraying, the atomization effect is good, and the paint film has a good decoration. It is especially suitable for the painting of large components requiring strong decorative finish paint, and is currently a relatively advanced painting equipment, which has a good prospect in the metal surface painting of steel structures, transformers and various equipment.

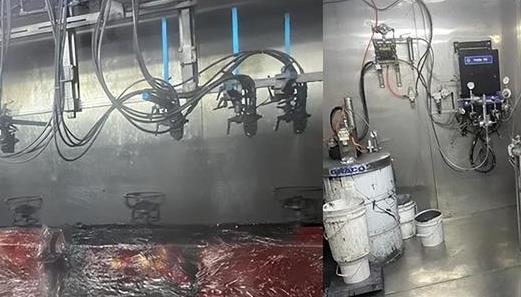

The principle of air mixing spraying is to use a special spray machine with a certain pressure ratio to pressurize the paint to 4 ~ 5Mpa, which is sprayed by the nozzle, and the compressed air after filtration and pressure regulation is sent to the air cap and sprayed by a specially designed hole.

Part of the compressed air is involved in the atomization process of the paint, that is, the expanded atomized paint is further atomized, so that it becomes finer and more evenly distributed, and the other part of the compressed air forms a wind curtain around the fan paint mist flow of the paint, limiting the flow of paint mist around and restricting its coating to the workpiece.

In short, the atomization force of mixed gas spraying comes from two aspects, one is from the liquid, that is, the paint suddenly depressurized and expanded after pressure; The second comes from the flow of gas, that is, compressed air, which promotes further atomization of the paint. These two elements are combined, called twin atomization, and this spraying method is called mixed gas spraying.

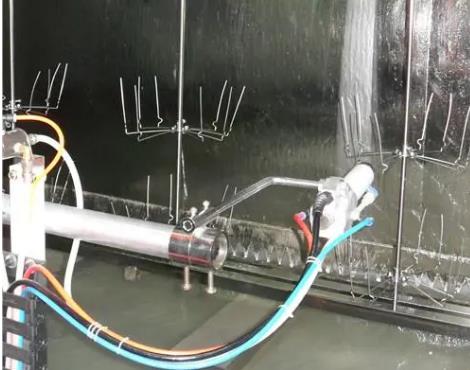

Air mixing gun

1. High coating quality: Due to the good atomization effect of mixed-air spraying, the spray droplets of paint are fine and evenly distributed; Compared with the air spraying method, the film obtained is uniform, smooth and fine, and can effectively overcome the film defects such as flow hanging.

2. Small coating consumption: mixed air spraying saves 20 ~ 50% paint than air spraying, and saves 10 ~ 25% paint than high pressure airless spraying. The reason is that the paint pressure used for mixed-air spraying is smaller than that of high-pressure airless spraying, and the pressure of compressed air used is much smaller than that of air spraying (0.1 ~ 0.2Mpa). Under such working conditions, the initial velocity of the paint sprayed by the nozzle is much lower than that of the high-pressure airless spraying, and the initial velocity of the compressed air is also greatly reduced, so that the outside of the fog flow is constrained by a ring air curtain, which restricts the flow of the paint mist to escape for four weeks. These two factors determine that the mixed air spraying method greatly reduces the flying of loose paint mist.

3. High production efficiency: due to the mixed air spray gun has a large amount of paint spraying, which is 10 times that of the air spray gun; The paint mist flow width is up to 400mm, while the air spraying range is only 70 ~ 100mm, the film thickness of the mixed gas spraying can reach 20 ~ 50um, and the air spray gun is only 10 ~ 15um, which can reduce the construction times, so the mixed gas spraying has a high production efficiency.

4. In the existing airless equipment can be converted into mixed gas spraying.