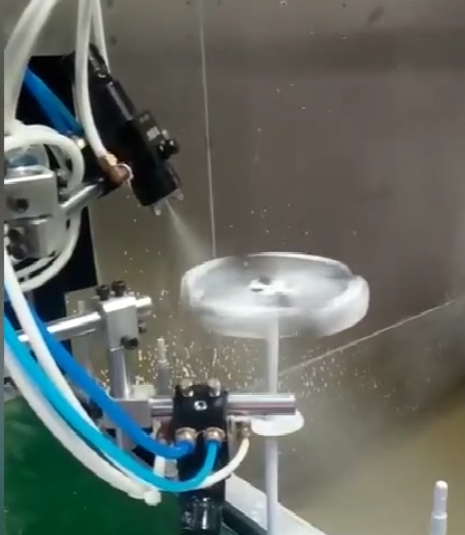

First, the structure and composition of the vortex nozzle

The vortex nozzle, also known as the vortex increase device, is mainly composed of a vortex chamber, a large diameter nozzle, a shrinking neck, a flow cone, a shunt, a guide blade, etc. A vortex chamber is arranged in the center of the structure, through the flow of fluid into the rotating vortex area, through the shrinkage of the neck and the change of the flow cone, the air flow in the nozzle is accelerated and the high-speed air flow is emitted.

Second, the principle of vortex nozzle

The principle of the vortex nozzle is to send air into a specially designed nozzle, forming a rotating body and the main air flow to merge with each other, thereby speeding up the speed of the material being ejected. Specifically, when the high-pressure gas enters the vortex chamber, a rotating body is formed due to the interior design. When a gas flows along a narrow path (necking), its flow speed must be accelerated due to the law of conservation of mass. This causes the air flow to concentrate further and ejects the nozzle, creating a high-speed airflow.

Third, the advantages and disadvantages of vortex nozzle

The vortex nozzle has the advantages of high efficiency and energy saving, easy to realize automation, and the internal parts of the nozzle are easy to clean and maintain. The disadvantage is that due to its vulnerability, it is not easy to withstand high pressure and high temperature gases and particulate matter, thus limiting its range of use.Fourth, the application field of vortex nozzle

The application range of vortex nozzle is very wide, which is mainly suitable for spray separation and accelerating the jet of air particles in the process of particle conveying, mixing, drying, crushing, granulation, etc.

(2) Fan nozzle

The fan-shaped nozzle has a slit nozzle and an impact (reflection) nozzle, and the liquid is sprayed through the spray hole to form a flat fan-shaped fog, and the eruption distribution area is a rectangle.

① Slit type (also known as slit type) fan nozzle. It consists of a washer, a nozzle, and a compression nut, as shown in Figure 8-18. The nozzle has two straight half-moon grooves in the nozzle, and the two grooves intersect to form a square spray hole.

The atomization principle of the slit fan-shaped nozzle: when the pressure liquid enters the nozzle, it is guided by the bottom of the inner half-moon groove, and the liquid is divided into two relative liquid flows. The two flow to the nozzle and gather, and are crushed into droplets by hitting each other. After ejection, the two sides of the outer half-moon trough are hit, broken and bound by it, as well as the guiding effect at the bottom of the outer half-moon trough, forming a fan-shaped mist ejection, and then further broken into thin droplets by colliding with relatively continuous air, and spraying on the lawn, as shown in Figure 8-19. Slit fan nozzle, the operating pressure is 150 ~ 300kPa, the droplet diameter is relatively thick, often used for spraying herbicides and pesticides.

② Impact sector nozzle. It consists of a nozzle cap, washer, nozzle, and nozzle body, as shown in Figure 8-20. Its atomization principle: the pressure liquid enters the nozzle through the body cavity of the nozzle, and the liquid flowing out of the nozzle impacts the deflector (also known as the reflector) to form a fan mist. The operating pressure of the nozzle is low, generally in the range of 40 ~ 100kPa, and the droplets are thicker, which can prevent drifting. The benefits are: the spray Angle is large (about 130°), while the general hydraulic nozzle only needs 60° ~ 90°, the spray volume is large, and it is mostly used for spraying herbicides.

(3) Impact nozzle

The impact nozzle is composed of a dispersion sheet, a nozzle, a nozzle cap and a gun barrel, etc. The nozzle is made into a conical cavity hole, and the exit aperture is generally 3 ~ 5mm. Its atomization principle: the high-pressure liquid from the spray hose flows through the nozzle to the exit, because the water section gradually decreases, the pressure gradually decreases, the flow rate gradually increases, forming a high-speed jet liquid column, shot to the distance. The ejected stream collides with relatively continuous air to defeat its own surface tension and viscosity, and is broken up into droplets and sprayed. It is assumed that the dispersion sheet is installed to block the liquid flow, so that the near lawn can be evenly dispersed and the spraying area can be increased. The impact nozzle is characterized by high pressure and large spray volume. The liquid pressure is 1500 ~ 2500kPa, the spray volume is about 30L/min, and the maximum range is about 15m.

In general, the working principle of the vortex nozzle is to achieve efficient injection by rotating fluid action and accelerating fluid speed, and plays an important role in the industrial manufacturing production process.