First, understand the perfluorohexanone fire extinguishing system

Before choosing the nozzle head of the perfluorophenone fire extinguishing device, it is necessary to understand the basic principle and working mode of the perfluorophenone fire extinguishing system. Perfluorohexanone is A chemical extinguishing agent commonly used to extinguish Class A, B and C fires. It is a colorless, tasteless, odorless liquid that has excellent electrical insulation properties, is non-conductive, and is harmless to electronic devices and sensitive equipment. Perfluorohexanone fights fires by absorbing heat and interfering with the chemical chain reaction of the fire source within the fire area.

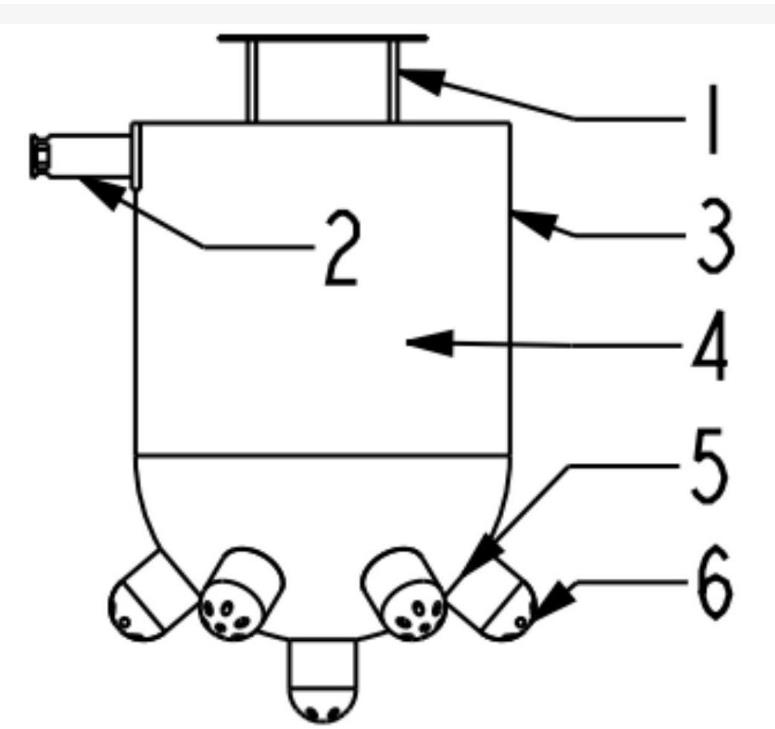

Perfluorohexanone fire suppression systems typically include the following components:

Fire detector: Used to monitor the occurrence of fire and send signals to the controller.

Controller: Used to activate the fire extinguishing system and control the release of the nozzle head.

Fire extinguishing agent storage tank: storage of perfluorohexanone fire extinguishing agent.

nozzle: Release the extinguishing agent to the fire source area.

When selecting the nozzle head of the perfluorophenone fire extinguishing device, it is necessary to consider the compatibility with other system components to ensure the normal operation and reliability of the system.

2. Consider environmental factors

The first step in selecting the nozzle head of a perfluorohexanone fire extinguishing device is to consider the characteristics and requirements of the installation environment. Different environments may require different types of nozzle heads, here are some factors to consider:

Type of fire: Different types of fires require different types of nozzle heads. For example, liquid fires and electrical fires may require different nozzle designs.

Temperature and pressure: Ambient temperature and pressure affect the rate at which perfluorohexanone is sprayed and evaporated. Ensure that the selected nozzle can operate properly under specific temperature and pressure conditions.

Risk areas: Some environments may have special risk areas, such as chemical storage areas or hot working areas. These areas may require specially designed nozzle heads to deal with potential hazards.

Spatial layout: Consider the layout of the building or equipment to determine the location and number of nozzle heads. Ensure that perfluorophenone is evenly distributed to the fire source area.

Third, understand the type of nozzle

Perfluorohexanone fire extinguishing systems usually use different types of nozzle heads to meet different application requirements. Here are some common nozzle types:

nozzle heads: These spray the extinguishing agent evenly to the fire source area. They are suitable for large open Spaces such as warehouses and factories.

Jet nozzle: Jet nozzle produces a high-speed jet, the fire extinguishing agent directed to the fire source. They are suitable for use where precise control and directional spraying is required, such as machinery and electrical equipment.

Foam heads: Foam heads mix fire extinguishing agent with foam to extinguish liquid fires. They are commonly used in high-hazard sites such as oil and chemical plants.

Special purpose nozzle: Some special applications require specially designed nozzle heads, such as those in high temperature environments or those with corrosion resistance.

When selecting the nozzle type, it is necessary to consider the application scenario and environmental characteristics to ensure that the fire extinguishing system can effectively extinguish the fire source in the event of a fire.

Fourth, flow and injection Angle

The flow rate and injection Angle of the nozzle are important parameters for selecting the nozzle head of the perfluorohexanone fire extinguishing device. These parameters directly affect the performance of nozzle head and the distribution of extinguishing agent. Here are some considerations:

Flow rate: Flow rate refers to the extinguishing dose from the nozzle per minute. Traffic is usually related to application scenarios and fire types. It is necessary to ensure that the flow rate of the selected nozzle is large enough to cover the fire source area in a short period of time.

Spray Angle: The spray Angle of the nozzle determines the coverage of the spray. Different fire sources may require different injection angles. The injection Angle can be vertical, horizontal, or other specific angles, adjusted as needed.

5. Material and corrosion resistance

When selecting the nozzle head of the perfluorohexanone fire extinguishing device, the material and corrosion resistance of the nozzle head should be considered. These factors are critical for long-term use and system reliability. Here are some relevant considerations:

Material: The nozzle is usually made of stainless steel, copper alloy or other alloys. Choose materials suitable for your specific environment to prevent corrosion and damage.

Corrosion resistance: Some environments may expose the nozzle to corrosive gases or chemicals. Ensure that the selected nozzle has good corrosion resistance to extend its service life.