Heat treatment process:

Heat treatment is the use of solid state heating, insulation, cooling methods to change the internal arrangement of steel, and then to improve the function of steel, but does not change the chemical composition and shape of steel. Heat treatment process can also be divided into general heat treatment, such as annealing, normalizing, quenching (also known as hardening treatment), external quenching, tempering and aging process methods; And chemical heat treatment, that is, in the process of heating and holding the workpiece in the medium of the furnace, the active atoms in the medium permeate the surface of the artificial part to change the surface chemical composition and arrangement, so that the surface has special mechanical, physical and chemical functions, such as carburizing, nitriding and cyaniding process methods.

spray nozzle parts also use a certain method, the process is the production workshop for a long time out, not the usual general process standards, but according to the material properties, parts shape standards to admit the low failure rate of the process and its parameters.

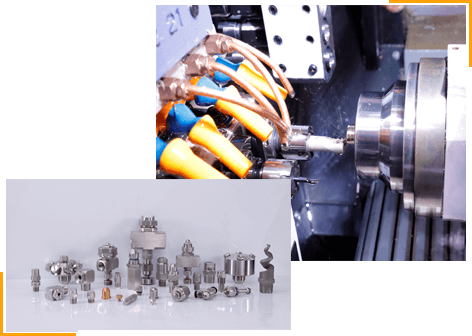

spray nozzle microhole machining is an important manufacturing process

spray nozzle microhole machining is an important manufacturing process. In recent years, it has been applied more and more to manufacture high-precision and high-precision spray nozzle parts to realize the manufacturing requirements of complex integrated spray nozzle.

The main technologies involved in spray nozzle microhole machining include impact machining technology, cutting machining technology, molding processing technology and laser cutting technology. The impact machining technology can be used to process large-size microholes, and the die-pressing technology can be used to process eccentric polygonal microholes. In addition, the use of laser cutting can achieve fine size more complex shape of microhole processing.

spray nozzle microhole machining can greatly meet the requirements of spray nozzle parts processing, can achieve very small flat or convex surface processing, especially can more accurately control the size of the spray nozzle and the working parameters of the spray nozzle, so as to better meet the customer's custom processing needs.

In addition to the processing of spray nozzles, spray nozzle microhole processing technology can also be applied to the manufacturing of other mechanical parts, such as the processing of automotive parts, aerospace, medical instruments, liquid crystal screens and other products, which can provide more accurate and perfect dimensions for the processing of these products.

In general, the application of spray nozzle microhole processing provides a reliable, efficient and accurate production method for enterprises to manufacture high-precision instruments and accessories, and provides a strong guarantee for achieving a more solid and reliable manufacturing effect.

Surface treatment process:

The appearance treatment process is to attach a covering layer to the surface of the part to achieve the purpose of rust prevention, decoration, etc. Generally divided into three categories: electroplating, such as chromium plating, nickel plating, cadmium plating, zinc plating, etc.; Appearance chemical treatment, such as oxidation, phosphating, commonly known as blue, hair (yellow) black is actually oxidation; Paint it. The metal parts of some spray nozzles require anti-corrosion, so different surface treatment processes are used according to different operating environmental conditions.

spray nozzle microhole machining - Advanced technology for producing precision parts

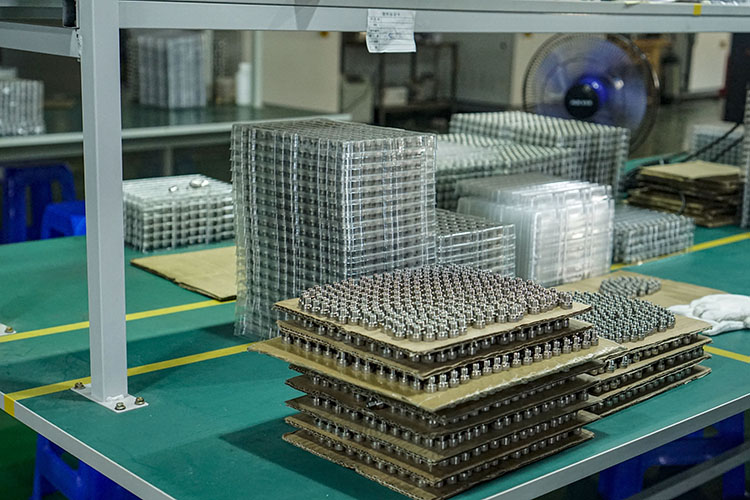

spray nozzle microhole machining is an advanced manufacturing process, which can be used to make various precision parts of different sizes. It works by applying a certain amount of pressure to the processed material to form very small pores. The size of this hole is the smallest size that can be achieved in the processing process, and it can achieve micron level of accuracy.

The perfection of the spray nozzle microhole machining surface is very high, and it can be easily manufactured into holes with high surface roughness, and it can also be made from a variety of different angles, which can effectively meet the diverse needs of customers. In some special cases, it can be used to make precise holes, and the machined surface can also remain very smooth.

spray nozzle micromachining This process and other processing technology has a very obvious advantage, because it is easy to operate, less time, low cost, long life, and it can manufacture precision, uniformity are very high parts. And it is an environmentally friendly processing method that does not produce harmful exhaust gas and waste.

In short, spray nozzle microhole machining is a high-precision, environmentally friendly process that plays an important role in the manufacture of precision parts.