Flow rate: Adjustable

Spray shape: round full cone

Spray angle: 30°、45°、60°、90°

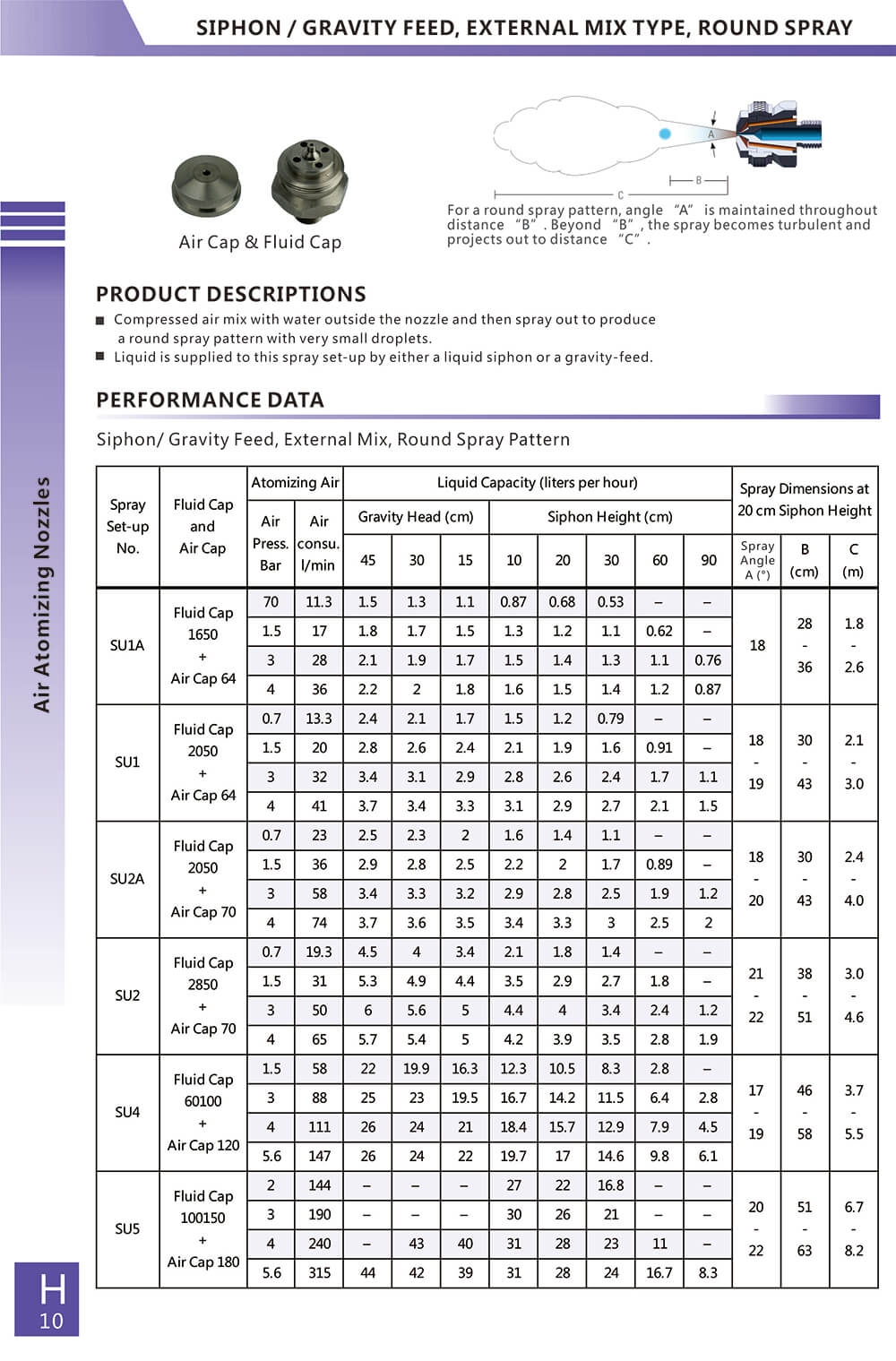

Atomizing device: internal mixing type

Atomization system: siphon/gravity atomization

Working pressure: 0.2kg ~4Kg

Connection size: 1/8、3/8、1/4、3/4、1/2 bspt

Material composition: SS304、303、316、316L other materials can be customized

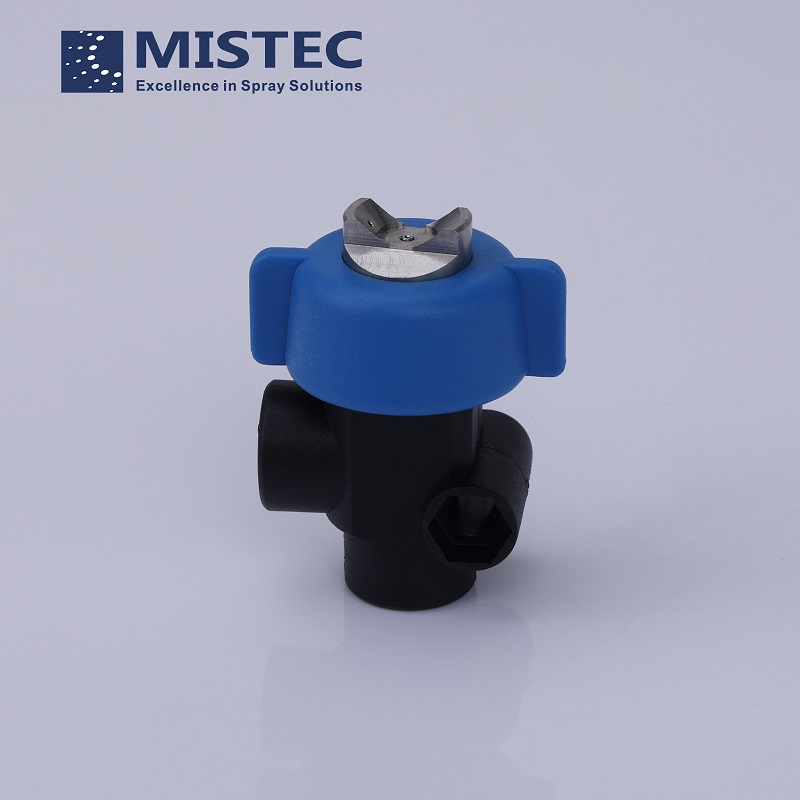

Siphon Air Atomizing Nozzle Cone Spray Adjustable Atomizing Nozzle

The spray shape of the adjustable siphon air atomizing nozzle is a round full cone, the impact area is a solid circle, and the spray Angle is 30 to 90 degrees. The siphon gravity power system is adopted, but the flow rate can be adjusted through the adjusting rod with the air atomizing nozzle.The details

Flow rate: AdjustableSpray shape: round full cone

Spray angle: 30°、45°、60°、90°

Atomizing device: internal mixing type

Atomization system: siphon/gravity atomization

Working pressure: 0.2kg ~4Kg

Connection size: 1/8、3/8、1/4、3/4、1/2 bspt

Material composition: SS304、303、316、316L other materials can be customized

Flow adjustable

there is an adjustment needle behind, can adjust the liquid flowThe spray and siphon power

This nozzle creates a circular spray by siphoning liquid and air together.

Connection mode

There are marking gas and LIQUID or marking AIR (AIR), LIQUID (LIQUID) on the nozzle, the connection usually uses 1/4 "internal thread connection, one end is connected with AIR pressure of 2-3 kg (0.2-0.3mpa), the other end is connected with static LIQUID, the nozzle produces negative pressure after ventilation, the static LIQUID is sucked in to mix atomization.Application

Siphon atomizing nozzles cover a wide range of industrial applicationsTemperature and humidity regulating paper, waste gas, ceramics, concrete, etc

Coating: release agent, deodorant, oil, surface treatment agent, rust inhibitor, lubricant, honey, insect repellent

Cooling: mold, casting, car body, coating

Cleaning: precision substrate, glass panel, etc