Background: a food machinery factory in Guangzhou, providing oiling machine for cake or biscuit production line for sino-Japanese Taiwan joint venture company.

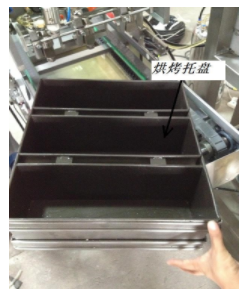

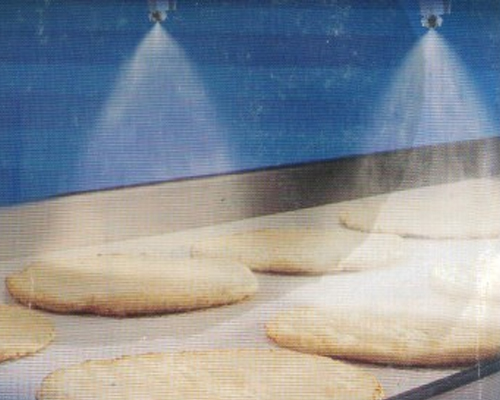

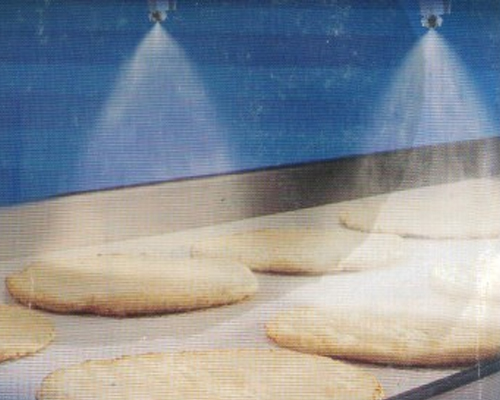

The function of oiler has two aspects: first, spray a thin layer of edible oil evenly on the inner surface of the baking plate, so as to facilitate the separation of cake and baking plate after baking;Spray cakes, cookies, or bread with a thin layer of cooking oil (butter, soy, vegetable oil, etc.) to flavor, color, or bake.

Because the spray liquid is more viscous oil liquid, spray volume is relatively small, uniform requirements, and can achieve uniform coverage of the tray.

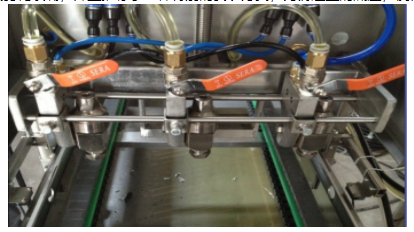

Solution: Because the medium is viscous liquid, it is more suitable to use air atomizing nozzle.Due to the discontinuity of the baking tray or pastry transfer process, it is required that the spray can be automatically controlled on/off, and the automatic air atomizing nozzle is more suitable.Our automatic air atomizing nozzle has a pneumatic actuated switch that can switch 180 times per minute.

The oiler we provided to the customer is equipped with three automatic air atomizing nozzles in one row, and a special installation method is recommended, which is a cast shaped base, which makes the structure very compact.The diagram below:

In addition, customers request to spray the lining of the baking tray or the cake on the conveyor belt with oil.When spraying the inner wall of the baking tray, the spray Angle is large and the atomization effect is good.We have improved a special nozzle based on the existing air atomizing nozzle. The structure of the liquid cap is different from that of our conventional air atomizing nozzle.As shown in the figure below, the jet hole on the liquid cap is deflected to make the spray Angle larger.