First, the basic principle of energy storage tank fire extinguishing system

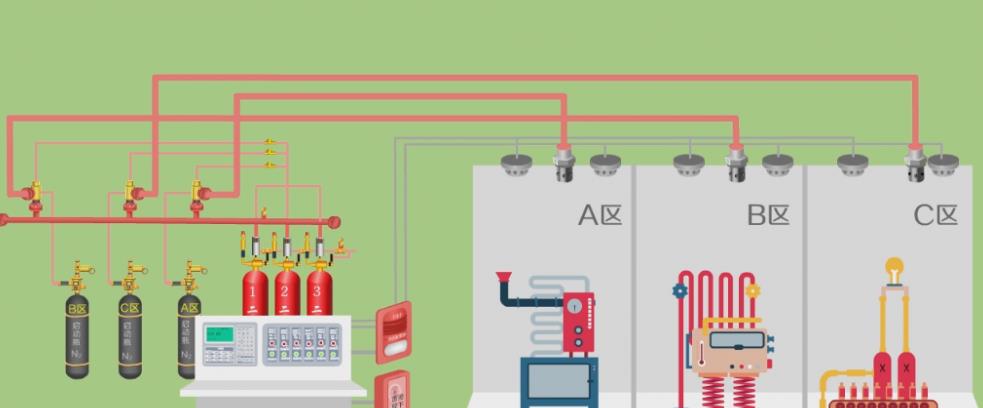

Before discussing the fire sprinkler nozzle layout of the energy storage chamber, let's first understand the basic principle of the fire extinguishing system of the energy storage chamber. The fire extinguishing system of the storage tank usually adopts automatic monitoring and control system to monitor the environmental status of the storage tank in real time by sensing temperature, smoke and other parameters. Once the fire risk is detected, the system will automatically activate the fire extinguishing device and implement the fire extinguishing operation. As one of the key components of the fire extinguishing device, the location and parameter setting of the sprinkler nozzle head will directly affect the effect of fire extinguishing.

Second, common energy storage cabin fire sprinkler nozzle layout scheme

1. Single central arrangement

One of the most common storage tank fire sprinkler nozzle layout schemes is to use a single central arrangement. In this scheme, the fire sprinkler nozzle is centrally arranged in the central position of the energy storage chamber, and is connected to the water source or the fire extinguishing agent storage through a pressure pipeline. This arrangement has the advantages of simplicity and low cost, but it also has some disadvantages. First of all, the central arrangement is difficult to meet the fire extinguishing needs of all corners of the energy storage module, and it is easy to form dead corners. Secondly, the fire sprinkler nozzle is concentrated in one point, and once the failure of the point, it will cause the entire system to fail.

2. Multi-point distributed layout

In order to solve the problem of single central layout, some designers adopt multi-point distributed layout. In this scheme, the fire sprinkler nozzles are dispersed in different positions of the energy storage cabin and connected to the fire extinguishing system through a network pipeline. This arrangement can cover all areas of the storage tank more comprehensively and improve the robustness of the system. However, due to the complexity of the pipeline network, the difficulty of system design and installation has increased accordingly.

3. Bottom layout and top layout

The arrangement of the fire sprinkler nozzle can also be divided into bottom arrangement and top arrangement according to its position. The bottom arrangement installs the fire sprinkler nozzle at the bottom of the energy storage chamber, and forms a fog-like protective layer covering the entire chamber by spraying fire extinguishing agent. This method can better cover the lower area of the energy storage tank, but the fire extinguishing effect of the upper area is relatively weak. On the contrary, the top arrangement can better cover the upper area by installing the fire sprinkler nozzle on the top of the storage tank, but the fire extinguishing effect of the lower area may not be as good as the bottom arrangement.

3. Key considerations for optimizing the layout of fire sprinkler nozzles in the energy storage chamber

1. Internal structure of energy storage module

The internal structure of the storage tank has a direct influence on the layout of the fire sprinkler nozzle. Different storage tank structures may require different fire extinguishing arrangements. For example, if there is a complex pipeline network or equipment layout in the storage tank, a more flexible multi-point distributed arrangement is needed to ensure that each area can be effectively covered.

2. Fire risk area classification

In the design stage of the storage tank, the fire risk area should be reasonably divided. The fire risk may vary in different areas. Therefore, you need to adjust the layout density and position of fire sprinkler nozzles according to the actual situation. High-risk areas can be densely arranged, while low-risk areas can moderately reduce the density of sprinkler nozzle heads to achieve cost-effective fire suppression.

3. Selection of fire extinguishing agent

The layout of the fire sprinkler nozzle also needs to consider the characteristics of the selected extinguishing agent. Different extinguishing agents have different inhibiting effects on the fire source, so it is necessary to choose the appropriate extinguishing agent according to the characteristics of the equipment and the energy storage system in the energy storage cabin. When arranging, it is necessary to consider factors such as the spraying range and diffusion speed of the fire extinguishing agent to ensure that the fire extinguishing agent can quickly cover the fire source when the fire occurs.

4. Fire sprinkler nozzle parameter setting

After determining the layout scheme of the fire sprinkler nozzle, it is necessary to set the parameters of the fire sprinkler nozzle reasonably, including the spray Angle, spray flow rate and spray pressure. The setting of these parameters is directly related to the fire extinguishing effect of the fire sprinkler nozzle. Excessive flow and pressure may lead to rapid evaporation of fire extinguishing agent in the air, affecting the fire extinguishing effect, while too small flow and pressure may not be able to effectively inhibit the fire source. Therefore, sufficient simulation and testing is required during the design phase to find the optimal parameter setting.

4. Case analysis: Application of optimized layout scheme

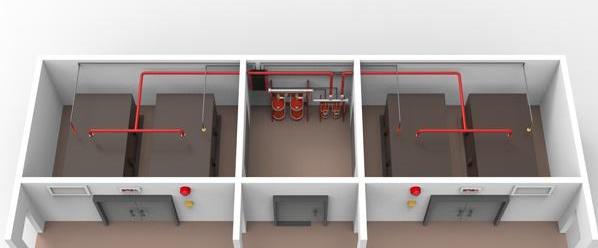

In order to better understand the optimization principle of fire sprinkler nozzle layout in storage tank, we take a specific storage tank as an example to analyze. The internal structure of the storage tank is complex, containing a large number of battery packs and control systems, and there are different fire risk areas.

1. Regional division

First, the storage module is divided into detailed areas. According to the density of the battery pack and the location of the control system, the storage module is divided into high risk areas, medium risk areas and low risk areas. The high-risk area mainly includes the area where the battery pack is concentrated, the medium-risk area is the area where the battery pack is relatively dispersed, and the low-risk area is the non-fire source area such as the control system.

2. Multi-point distributed layout

According to the fire risk in different areas, the multi-point distributed layout scheme is adopted. In high-risk areas, the higher density of sprinkler nozzle heads ensures that fire sources can be quickly and effectively suppressed. The sprinkler nozzle layout density is moderate in the medium-risk area, while the sparser layout is used in the low-risk area to reduce the cost.

3. Combine the bottom layout with the top layout

In the actual arrangement, the characteristics of the bottom arrangement and the top arrangement are combined. For high-risk areas with dense battery packs, the bottom arrangement is adopted, and a fog-like protection layer is formed through the bottom fire sprinkler nozzle to cover the upper and lower parts of the battery packs. For more dispersed low-risk areas such as control systems, the top arrangement is used to ensure effective coverage of the entire area.

4. Fire extinguishing agent selection and parameter setting

According to the characteristics of the battery pack, select the extinguishing agent suitable for lithium battery fire, and set the parameters of the fire sprinkler nozzle according to the actual situation. Through simulation and testing, parameters such as injection flow rate and injection pressure of fire extinguishing agent are determined to ensure that the fire extinguishing effect can be formed quickly when the fire occurs.

The optimization of fire sprinkler nozzle layout is an important part to ensure the safe operation of energy storage system. Through reasonable layout scheme, the fire extinguishing effect can be improved, and the fire damage to equipment and environment can be reduced. When optimizing the layout plan, it is necessary to consider multiple factors such as the internal structure of the storage tank, fire risk area division, fire extinguishing agent selection and parameter setting, and make reasonable adjustments based on the actual situation. Through the analysis of examples, we can see that different layout methods in different areas, combined with the bottom layout and the top layout, is an effective optimization scheme. In the future design and construction of energy storage system, the optimization of fire sprinkler nozzle layout will continue to play a key role, providing a strong guarantee for the sustainable development of energy storage technology.