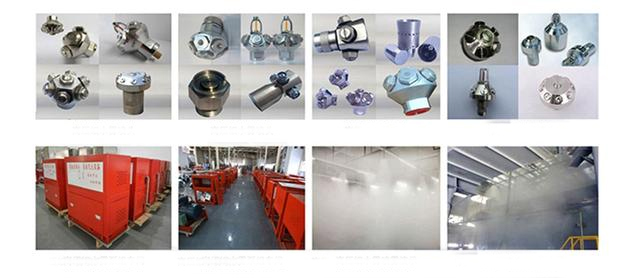

(1) Classification of water mist nozzles

1. Classification by action mode: open water mist nozzle, closed water mist nozzle;2, according to the production principle of fine water mist classification: impact water mist nozzle, centrifugal water mist spray nozzle;

3, according to the number of holes classification: single hole fine water mist nozzle, porous fine water mist nozzle;

4, according to the material classification: stainless steel water mist spray nozzle, brass water mist spray nozzle;

5, according to the applicability of classification: general water mist nozzle, special water mist nozzle;

6, according to the function of the classification: fire nozzle, cooling protective nozzle, water mist nozzle.

(2) the choice of water mist nozzle

1. For places where the spray hole of the water mist nozzle is easily blocked by external foreign matter, the water mist nozzle with corresponding protective measures should be selected and does not affect the spray effect of fine water mist. For example, the water mist nozzle with dust-proof cover (end cover) should be selected for dust places, but the water mist should not be blocked and the damage caused to personnel during the spray;2. For the floor inter layer of electronic data processing room and communication room, water mist nozzles suitable for low space should be selected;

3. For closed system, the water mist nozzle with response time index no more than 50(m.s)0.5 should be selected, and its nominal operating temperature should be 30℃ higher than the maximum ambient temperature, and the same thermal sensitive performance should be used in the same protection area;

4, for corrosive environment, should choose anti-corrosive materials or with anti-corrosive coating nozzle;

5, for the fine water mist fire extinguishing system of electric fire danger places, it is not suitable to choose the impact atomizing fine water mist nozzle.

(3) Layout requirements of water mist nozzle

1, closed fire protection system nozzle layout requirements

The nozzle layout of the closed fire protection system should ensure that the fine water mist spray evenly and completely cover the protected area; The distance between the water mist nozzle and the wall should not be greater than 1/2 of the maximum layout spacing of the water mist nozzle; The distance between the water mist nozzle and other occlusive objects should ensure that the occlusive objects do not affect the normal spray spray nozzle, when it is unavoidable, compensation measures should be taken; The distance between the temperature sensing component of the water mist nozzle and the ceiling or beam bottom should not be less than 75mm, and should not be greater than 150mm. When the ceiling is set in the place, the water mist nozzle can be attached to the adjacent ceiling arrangement.

2, open fire protection system nozzle layout requirements

The water mist nozzle layout of the open system has the same requirements as that of the closed system, but for the cable tunnel or sandwich, the water mist nozzle should be arranged on the upper part of the cable tunnel or sandwich, and the fine water mist should be able to completely cover the whole cable or cable bridge.3, partial application mode of open fire protection system nozzle layout requirements

The layout of water mist nozzle should ensure that the water mist can fully contain or cover the protected object or part, and the distance between water mist nozzle and protected object should not be less than 0.5m. For the protection of indoor oil-immersed transformer, transformer height more than 4m, nozzle should be arranged in layers; If the cooler is more than 0.7m away from the transformer body, the water mist nozzle should be added in the gap; The nozzle should not be directly aligned with the high pressure line inlet sleeve; If the oil collecting pit is arranged below the transformer, the water mist nozzle arrangement should be able to make the fine water mist completely cover the oil collecting pit.

4. Spare parts of water mist nozzle

The system shall store spare water mist nozzles according to the model and specification of water mist nozzles. The number of spare water mist nozzles shall not be less than 1% of the total number actually designed and used, and shall not be less than 5 respectively.Ps:

(1) The number of spares for water mist nozzles of the automatic nozzle system shall not be less than 1% of the total number of water mist nozzles installed, and each spares shall not be less than 10.

(2) To test the sealing performance of closed water mist nozzles, 1% of each batch of water mist nozzles will be randomly selected, and no less than 5 of them will be used as test water mist nozzles. When the test of 1 water mist nozzle is unqualified, another 2% is extracted, and no less than 10 water mist nozzles on the field are repeated test.

.png)