Spray shape: 6 jet hole

Spray Angle: narrow

Atomizing device: internal mixing, external mixing

Atomization system: pressure atomization

Working pressure: 0.7kg ~4Kg

Connection size: 1/8inch, 1/4inch, 1/2inch, 1inch

Application scenarios: humidification, dust removal, cooling, lubrication

Material composition: stainless steel, other materials can be customized

Pressure atomizing nozzle 15 to20 degree Angle adjustable air atomizing nozzle

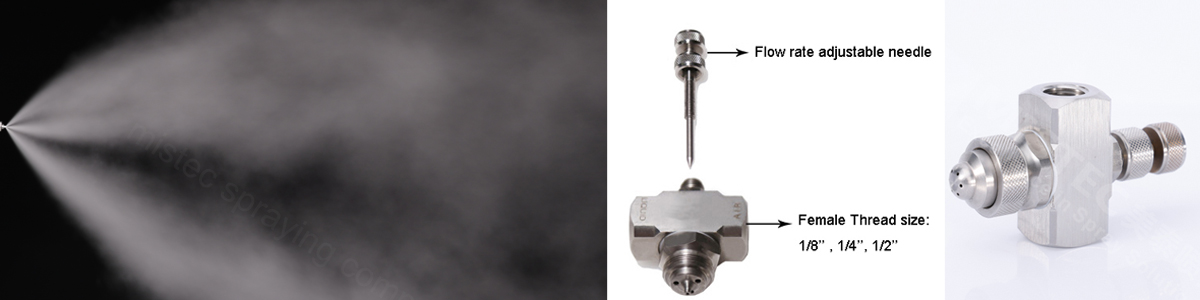

The pressure air atomizing nozzle is designed with 6 holes on the nozzle cap, and the spray atomization is delicate. Spray can be adjusted by flow regulating rod. Using external pressure for liquid atomization, pressure can be 0.7kg ~4Kg. Air and liquid air connection aperture is 1/8" 1/4",3/4"1/2" 1", 1/4",3/4" specifications are popular. We also support custom services. Provide air atomizing nozzles with actual specifications to customers.Spray pattern

There are 6 holes on the nozzle cap for fine atomization. Spray can be adjusted by flow regulating rod.

Connect ways

Air and liquid connection aperture is 1/8" 1/4",3/4"1/2" 1" NPT or BSPT, and 1/4",3/4" specifications are popular.Product features: atomized particles evenly small, average atomized particle diameter of 50μm, adjustable flow size, not blocking, simple maintenance

Application scenarios: humidification, dust removal, cooling, lubrication

Material composition: stainless steel, other materials can be customized

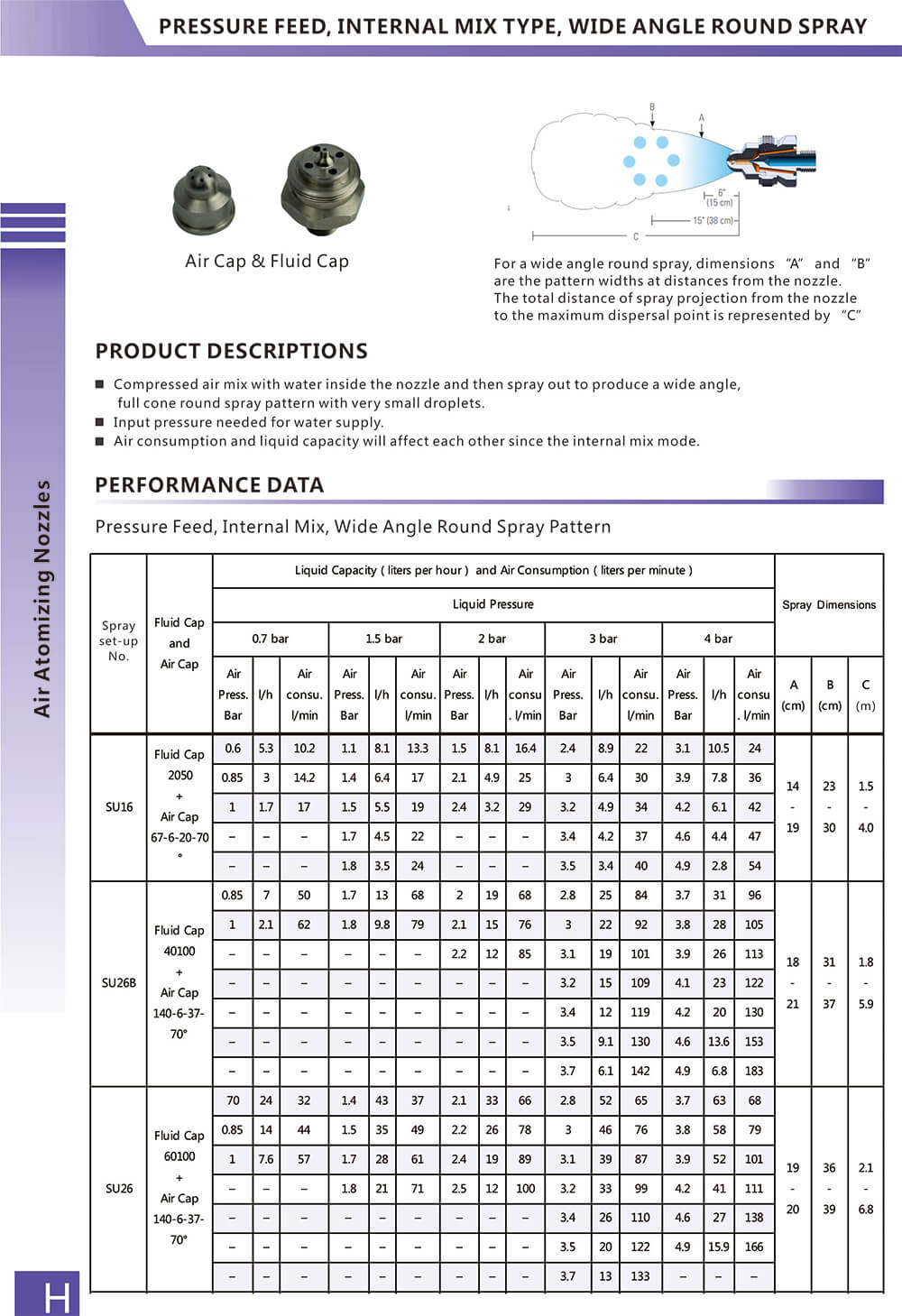

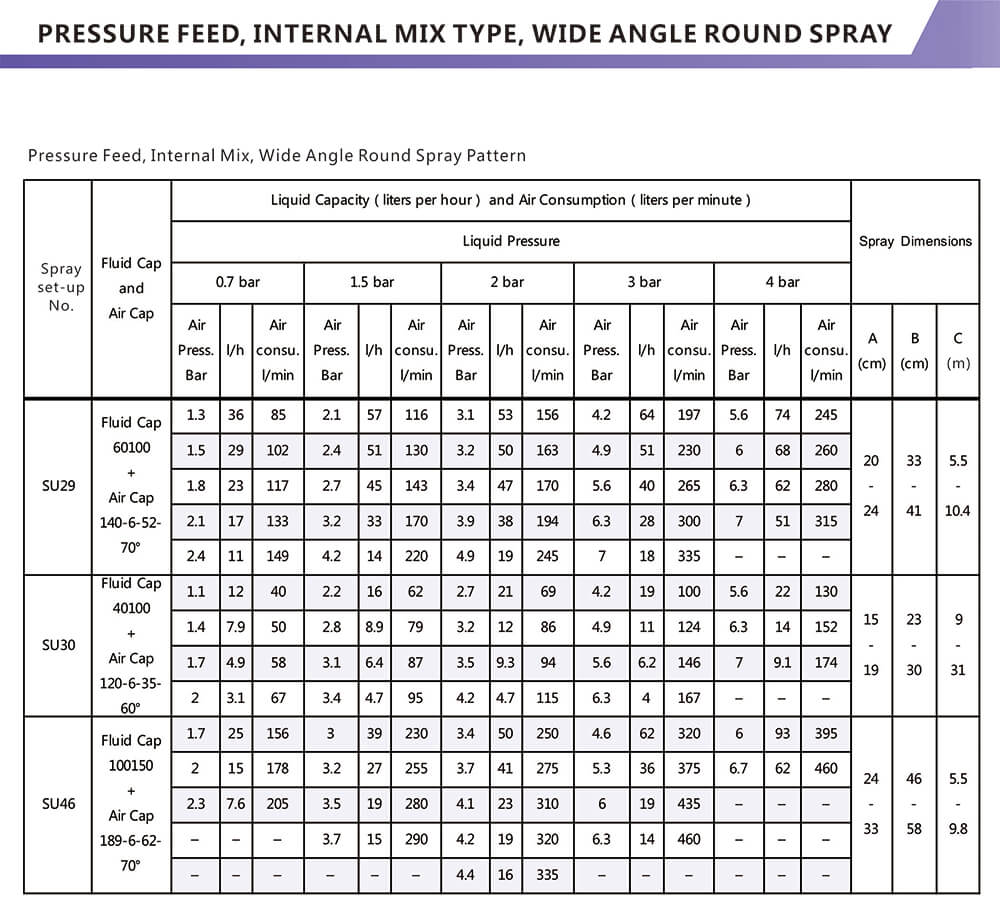

Pressure atomization system

The nozzle atomization system adopts external pressure supply mode, the pressure range can be 0.7-4kg.

Application scope

1 wetting and rust removal 2 air humidification 3 chemical treatment 4 chemical agent spraying 5 liquid spraying 6. Humidification of tobacco leaves 7. Tablet coating 8. Evaporative cooling of flue gas 9. Wax fruit spray 12. Glaze tile

Applicable industry

Electronics, chemical industry, environmental protection, steel, machinery, coating, electroplating, textile, automobile, paper making, medicine, food and other industrial production fields

Installation

Its installation methods are pipe connection, corner code connection, bracket connection and so on. The installation and connection methods vary according to actual usage requirements.

.jpg)