Siphon atomizing nozzle Internal Mixed Wide Angle Air atomizing nozzle

Wide Angle air atomizing nozzle is pressurized by siphon power or gravity power system to air and liquid. Using air and liquid in the nozzle inside the impact of mixing into a very fine atomized particles design. The nozzle cap has multiple holes to make the spray direction of the nozzle wider.Adjustable flow rate

This siphon atomizing nozzle has flow adjuster function and adjusts liquid flow by adjusting flow control lever.Spray pattern

The spray Angle is wide, and there are multiple holes on the nozzle cap. These holes make the spray spray in multiple directions. Generally, the nozzle cap of the wide-angle atomizing nozzle uses 6 or 8 and 12 holes. The specific design shall be in accordance with the actual requirements of users.

Spray shape: porous cone

Spray Angle: wide cone

Atomizing device: internal mixing type

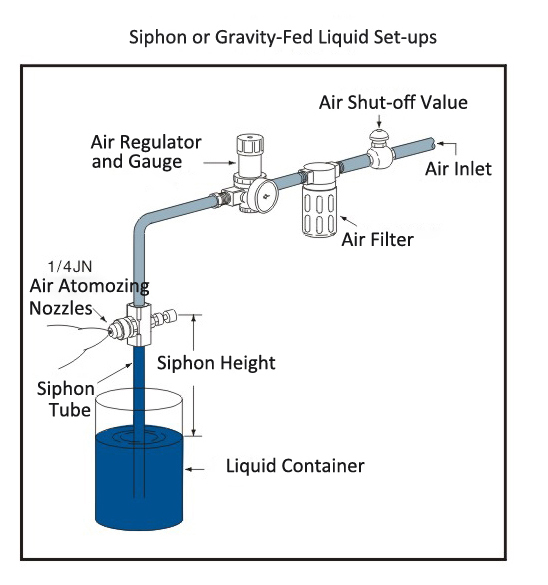

Atomization system: siphon/gravity atomization

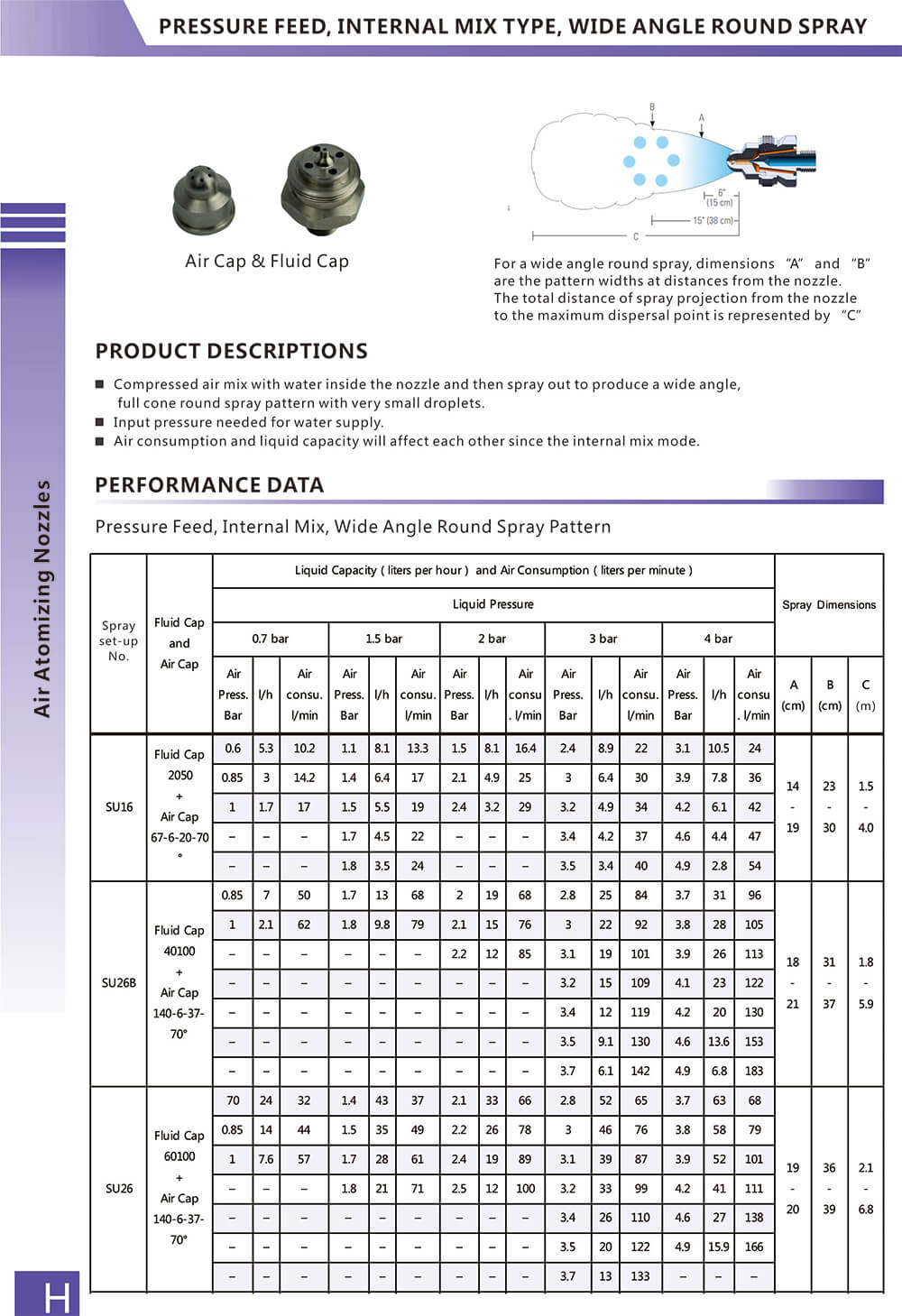

Working pressure: 0.1kg ~4Kg

Connection size: 1/8inch, 1/4inch, 1/2inch, 1inch

Application scenarios: humidification, dust removal, cooling, lubrication

Material composition: stainless steel, other materials can be customized

Product features: atomized particles evenly small, average atomized particle diameter of 50μm, adjustable flow size, not blocking, simple maintenance

Siphon power

Siphon power

Siphon atomizing nozzle can adjust the liquid flow, in the same environment without changing the air pressure and liquid pressure, can also produce spray to meet the requirements, so it has a strong adaptability.

Siphon atomizing nozzle can get more fine droplet spray by increasing gas pressure or decreasing liquid pressure, resulting in higher gas flow rate liquid flow rate ratio. Siphon atomizing nozzle produces fine droplet spray, which can volatilize the surrounding environment with excellent humidification effect. The nozzle is the ideal choice for places requiring effective humidity control. The special internal design allows the liquid and gas to mix evenly, producing a spray with the size of a micro droplet. In general, a much finer droplet spray (about 30 microns) can be obtained by increasing the gas pressure or decreasing the liquid pressure, resulting in a higher ratio of gas flow rate to liquid flow rate.

.jpg)