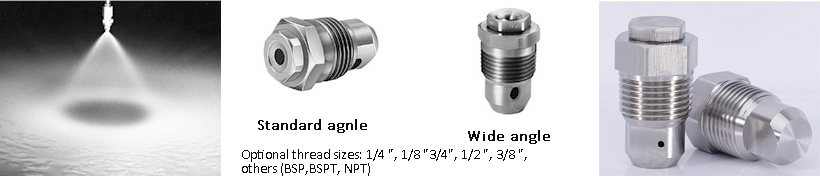

The inline entry hollow cone nozzle adopts the structure design of the beeline direct swirl cavity to produce hollow cone spray and form a ring striking area.Spray Angle range 60-90 degrees.inline entry type hollow cone nozzle spray evenly distributed, small to medium spray droplets, pressure and flow wide application.

● Spray pattern: Hollow Cone ring impact area

● Spray angles: 60°to 90°

● Flow rates: 1.1 to 67 L/min @1.5 bar

●Thread Type:NPT, BSPT

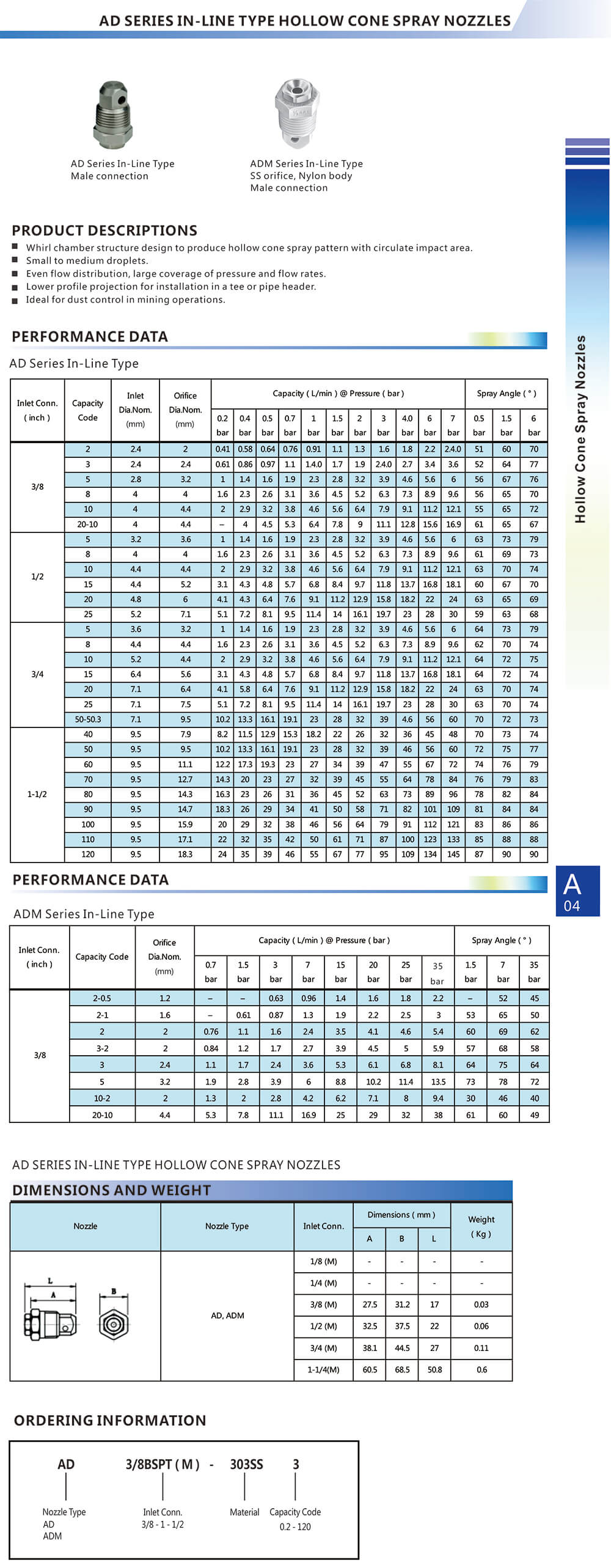

Ordering Information

AD 3/8 – Brass 10

Material: 303SS, 304SS, 316SS, BRASS

Features of the inline entry hollow cone nozzles

Features of the inline entry hollow cone nozzles

• Caps of the same size can be changed.• Small droplet, large and unobstructed channel.

• Smaller side projection when mounted on tee or spray rod.

•The swirl chamber is designed to generate a hollow conical spray to form a ring strike area.

•Large, unobstructed liquid channels reduce clogging.

•Small to medium spray particles.

•Uniform distribution, wide application of pressure and flow.

•Smaller side projection when mounted on tee or spray rod.

•Caps of the same size can be interchangeable, increasing diversity.

•Very suitable for dust removal field.

Applications

• Brine spray• Spray cooling

• Metal treatment

• Dust control

• Product degreasing

• Gas washing, cleaning and cooling