Key words: dust pollution; Open space; Spray dust removal; Energy conservation and environmental protection

In the smelting, processing and production process of iron and steel and non-ferrous metals, the stacking, transfer and loading and unloading of materials often produce a lot of dust pollution, especially in dry weather and windy conditions, will seriously pollute the factory environment, bring great harm to the health of employees. Usually the quantity of these dust points is very much, distribution is extensive, be located in each craft place in production, and the kind of dust, granularity, temperature, humidity, and the reason that produce also are each not identical, not easy management.

Usually when it comes to efficient dust removal, the first thing that comes to mind is cloth bag dust collector or electric dust collector. In fact, these two types of dust removers are not suitable for use on dust pollution points in open Spaces.

On the one hand, ventilation equipment is difficult to guarantee the open space in the convulsions of all dust emissions are to be pumped in, there will be more dust removing dead Angle, where the negative pressure is not enough, dust can not be away, would lead to excessive dust concentration, environmental protection is not up to standard, at the same time in other places also pumped in a lot of clean air, increase the subsequent processing load.

On the other hand, ventilation equipment needs a lot of pipe installation, fan and bag dust collector, electrostatic precipitator, huge investment, at the same time, fan consumption of electric energy is also very large, maintenance is also costly.

The investment and operation cost of ventilation dust removal are very high, and it is not an energy saving dust removal method. And the traditional water spraying method has poor dust suppression ability, especially for the inhalable dust below 10um has no suppression ability, the dust removal effect is very poor, and too much water, will significantly increase the water content of the material, easy to cause material agglomerate, but also produce sewage. Therefore, they are not ideal solutions for such dust pollution.

Spray dust removal is very suitable for dust pollution in open space. Practice shows that efficient spray dust removal with a very small amount of water can achieve more than 90% of the dust removal efficiency, or even more than 98% of the dust removal efficiency, and it is especially suitable for the dust removal in open space with many dust points, wide space and many processes.

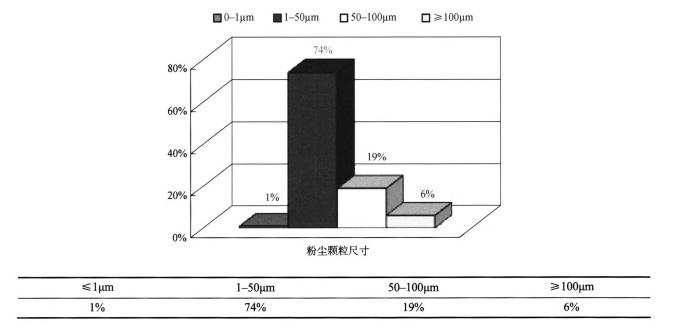

The above is the dust data of returning blast furnace material from a customer of our company. According to the measurement and analysis, 93% of the dust floating in the air has a particle diameter between 1um and 100um. Dust particles larger than 100um will naturally settle quickly in the air due to gravity factors, while dust particles with a diameter between 1-00um will stay in the air for a period of time, and dust particles with a diameter smaller than lum will float in the air for a long time. Therefore, dust pollution particles with diameters between 1-100um are our main dust removal objects.

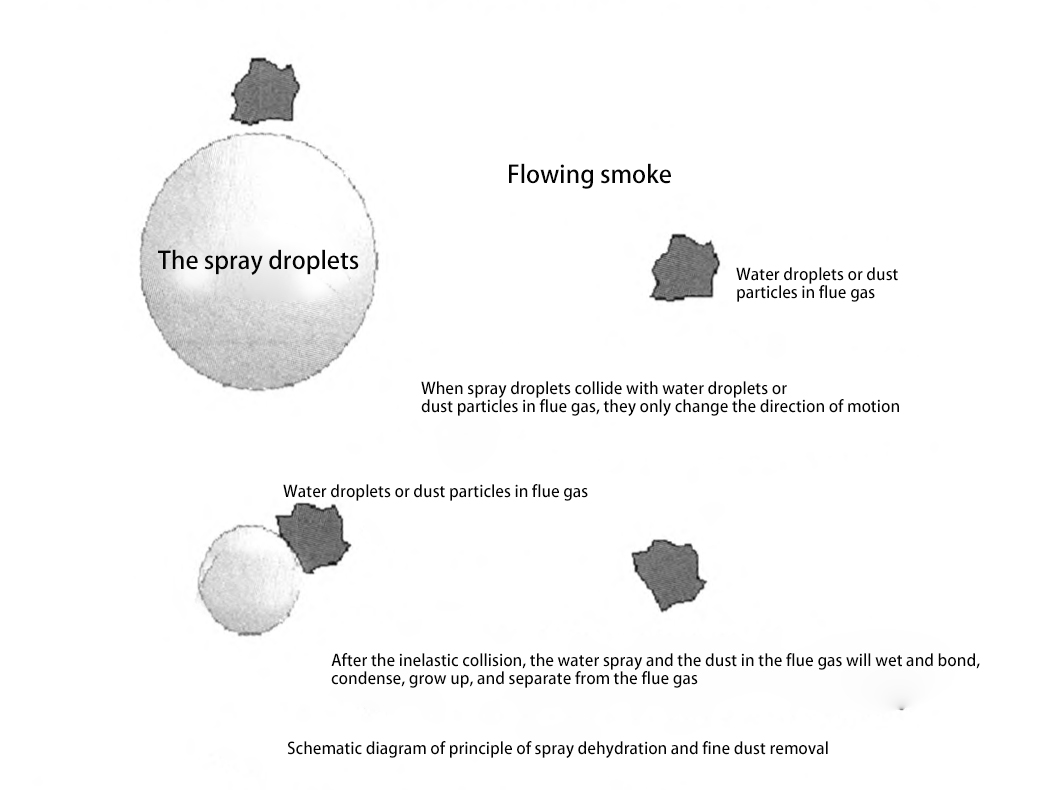

Theoretical study shows that when water mist particles collide with dust particles, the water mist particles will not combine with dust particles, but only change the direction of dust particles' movement. When the size of water mist particles and dust particles is close to a certain multiple, inelastic collision will occur, water mist particles and dust particles are effective adsorption and agglomeration, growing up, and finally settled by gravity, so as to achieve dust suppression and dust removal.

Therefore, atomizing droplets with appropriate particle size ratio can effectively remove floating dust particles. According to our company's spray dust removal experience, more than 90% of the particle diameter of hydrophilic dust floating in the air is between Lum and 100um, which is the most suitable method for spray dust removal.

According to the previous successful experience, spray dust removal method can effectively remove more than 90% of the floating dust pollution in the process of stacking, transporting and loading and unloading materials, which is the most effective and suitable dust removal solution. The figure below is an application case of spray dust removal in the silo dropping point of our company. The measured spray dust removal efficiency reaches 98.2%.

| Before spraying dust removal | After spray dusting | Dust removal efficiency | |

| Dust concentration | 106.8mg/Nm3 | 1.85mg/Nm3 | 0.982 |

In the practical application of spray dust removal, factors such as dust type characteristics, temperature, humidity and equipment layout should also be considered. At the same time, the speed, pressure, flow rate, spray coverage and system configuration all play a crucial role in the dust removal efficiency, which directly determines the effect of efficient spray dust removal device.

As the world's leading professional nozzle multinational company with more than 70 years of history, it has more than 70 years of experience in providing a variety of solutions for the industrial field. It has built the world's leading nozzle and spray system R&D center, and has a team of professional application engineers with rich experience. SPR spray Systems has been focusing on the development, design, manufacture and sales of nozzles, spray guns and automatic control systems, and has in-depth research in the field of spray dust removal.

At present, we in the iron and steel industry material stacking, loading and unloading, transportation, processing and other aspects for many customers to solve the problem of dust pollution, help customers to meet the environmental standards.

according to the types of the dust pollution to each point granularity, the parameters such as temperature, humidity, hydrophilic, speed of research, combined with our spray research and experience of more than 70 years, our efficient spray dedusting unit combined with professional design of spray dust control system, in every process of the steel industry has a very good spray dusting effect, dust removal efficiency is over 90%, basic Some even reach 99%. The following are some open dust pollution points suitable for spray dust removal:

| The sintering | Silo dropping point, belt transfer point, truck unloading point, sintering batching system, sintering ring cooler dust |

| Ironmaking | Blast furnace outlet, silo dropping point, belt transfer point, blast furnace feeding system, truck unloading point, truck loading point, stacking machine, reclaiming machine, raw material yard, dump machine |

| Steelmaking | Tundish turning over, discharging point, belt transfer point, secondary dust of converter, third dust of workshop, cooling and dust removal of slag tank |

| Hot rolled | The finishing mill exports smoke |

Compared with other dust removal schemes, spray dust removal equipment can save more than half of the investment than ventilation dust removal equipment, and at the same time, the operation cost is very low, only a small amount of water consumption and a very small amount of compressed air, the operation cost is greatly reduced. Reliable operation, low failure rate, basic maintenance free.

The dust pollution points of the four adjacent blanking points were comprehensively compared as follows:

| Ventilation and dust removal (cloth bags, static electricity) | Spray dusting | Can save | |

| Investment in equipment | 5,700,000 | 2,400,000 | 57.9% |

| Energy consumption (per year) | 618,000 | 178,200 | 71.2% |

| Maintenance cost (per year) | 948,000 | 160,200 | 83.1% |

| Dedusting effect | 10mg/Nm | 5mg/Nm3 |

We hope that with our years of spray experience and technology, we can solve the dust pollution in open space in a more energy saving and environmental friendly way for customers, and help customers meet the environmental standards.

.jpg)

.jpg)

.jpg)

.jpg)