Working pressure:

0.3--35bar

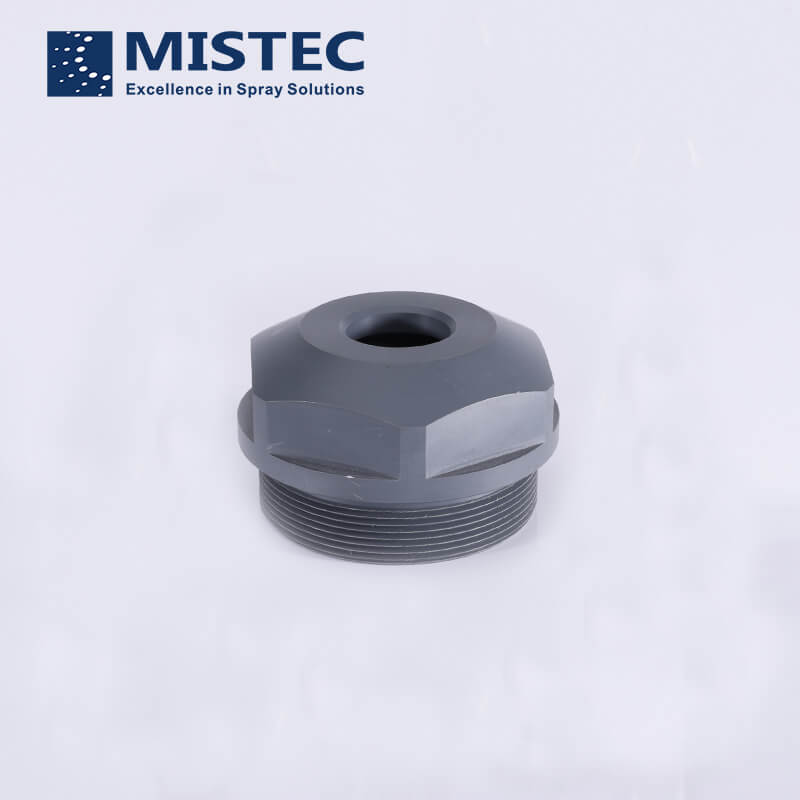

Material:

Stainless steel(303,304,316,316l)

Spray shape:

full cone spray pattern

Spray angle:

15-120 degree

Thread size:

3/8'',3/4'',1/2'',1'',1-1/2'',2'',2-1/2''BSP, NPT or others

Stainless Steel is a metal material stainless steel (Stainless Steel) refers to air, steam, water and other weak corrosion medium and acid, alkali, salt and other chemical etch medium corrosion of steel, also known as stainless acid resistant steel. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements. Stainless steel is not easy to produce corrosion, pitting, corrosion or wear. Stainless steel is also one of the strongest building metals. Because of its excellent corrosion resistance, stainless steel enables structural components to maintain engineering integrity permanently. Chrome-containing stainless steel also has mechanical strength and high extensibility, and is easy to manufacture parts to meet the needs of architects and structural designers.

The characteristic of the standard full solid cone nozzle is that it can produce a full solid conical spray shape. The spray area is circular and the spray Angle is between 43° and 106°. BB series nozzles have detachable caps and blades, and can be well matched with manifold and multi-branch pipe, full solid cone nozzle design method enables it to remove the working end (cap and blade) from the nozzle for maintenance and cleaning, without having to remove the nozzle body from the manifold, which not only saves the disassembly time and convenient cleaning. full solid cone nozzle have been precisely manufactured to reach precise dimensions, ensuring accurate and reliable performance. At the same time, the difference between the wide-angle full solid cone nozzle and the standard full solid cone nozzle is that the characteristics of the wide-angle full solid cone nozzle is able to produce the shape of the full solid conical spray, and the spray area is circular at the same time, the spray Angle can be between 120°-125°, so that the covered area increases under the condition of the same height, and the flow rate also increases.

Stainless steel advantages: corrosion and rust, bright color, full solid material

Application range of full solid cone nozzle: It is widely used in surface treatment, waste treatment fire extinguishing deaeration, spray, dust removal, all kinds of work piece cleaning application, applicable to industries: electronics, chemical industry, environmental protection, steel, machinery, painting, electroplating, textile, automobile, papermaking, medicine, food and other industrial production fields.

.jpg)