If the water mist particles produced by the dry fog dust suppression system are larger than dust particles during operation, the direct contact between water mist particles and dust particles will be reduced, which directly affects the coal dust prevention effect. Therefore, when the dry fog dust suppression device is running, appropriate measures should be taken to control the water mist particle size generated by the device within a reasonable range, or protect the water mist particle size and dust particle size. In the state of mutual thickening, the effect is good, improve the cohesion between water mist particles and dust particles, increase the probability of agglomeration between the two, improve the operation effect of dry fog dust suppression device.

The feature of dry fog dust suppression system

* The diameter of the fog particles is small, only 1-10u-m size, it has a better capturing effect on the inhalable dust about 5u-m or smaller;

* The direction of the spray is accurate and powerful, the speed of the fog cable is suitable, and the speed of capturing, shielding, shielding and cutting off the dust diffusion is suitable;

* Large amount of fog, large length of fog cable. In addition, the amount of fog and the length of the fog cable can be adjusted.

Dry fog dust removal equipment composition:

Adopt modular design technology. It is composed of dry fog dust suppressor, spray assembly, air compressor, air storage tank, water and gas connection pipeline system and automatic control circuit.

The benefit of dry fog dust suppression system

Dry fog dust suppression system breaks through the traditional dust suppression method. High dust suppression efficiency and low water consumption. The adverse impact of atmospheric environment also avoids the damage of dust to the respiratory system and cardiovascular system of on-site personnel. In addition, it reduces the risk of explosions in high-dust environments.

Dry fog has significant advantages in fog distance, fog amount and particle size. It is more suitable for fixed point dust suppression in dust concentration area, such as screening tower, discharge port, etc. In addition, dry fog dust suppression has little effect on material humidity, so it is also very suitable for the workshop with fine requirements for humidity control.

The principle of dry fog dust suppression system

The micron level dry fog dust suppression system is an acoustic oscillator driven by compressed air. It through the sonic boom of high frequency sound waves acting on the dry fog nozzle cavity, the water is highly atomized, the production of 10μm below the water mist particles (diameter of 10 microns of the following fog) dry fog spray to the dust point, so that the water mist particles and dust particles collide, bond, polymerization and increase, and under the action of its own gravity settlement, to achieve the effect of dust suppression.Dust s can accumulate and expand by binding with water, but the finer dust (e.g. PM10-PM2.5) can only be reduced when water droplets are small (e.g., dry fog) or when chemicals (e.g., surfactants) are added to reduce water surface clumping together under tension. If the diameter of the water mist particles is larger than the diameter of the dust particles, the dust will only move with the airflow around the water mist particles, the water mist particles and dust particles rarely contact or do not contact, can not reach the dust suppression effect. If the size of the water mist particles is close to that of the dust particles, as the dust particles move along the air stream, they will collide with the water mist particles and bind together. The smaller the spray particles, the greater the probability of clumping. As the condensed dust mass grows larger and heavier, it becomes easier to land. Water mist on the dust "trapping" effect of formation.

The effect of dry fog dust suppression system

Dry fog system spray fog effect is good, spray distance, cover a wider area.The application of Dry fog dust suppression system

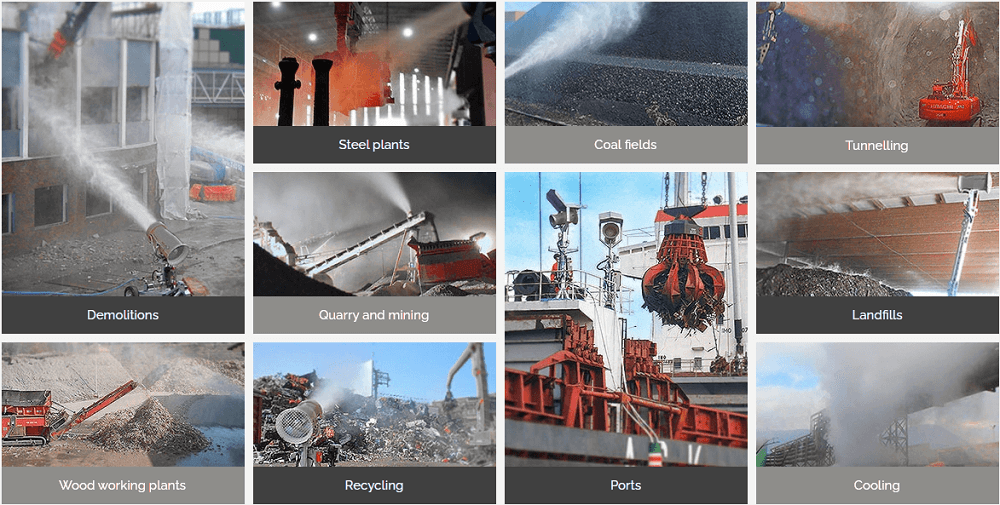

Dry fog dust suppression system with its good dry fog dust suppression effect, people often use it in Coal yard, mine, metallurgy, thermal power plant, port and other bulk material transfer and dust collection points, such as: tipper, belt transfer tower, automobile (train) discharging port, receiving chute, loading building, round (bar) type silo, finished product warehouse, original coal bunker, ship unloader, loading machine, etc.

.jpg)

.jpg)

.jpg)

.jpg)