At present, the widely used dust removal technology mainly consists of dry dust removal and wet dust removal. Dry dust removal to bag dust removal and electrostatic dust removal two technologies are widely used, the dust removal process is similar: the polluted air is inhaled dust removal equipment, after treatment, the clean gas is discharged into the atmosphere. Therefore, dry dust removal effect is better for the air that has entered the air intake chamber. However, for the unorganized discharge of dust air, the effect of dust removal is greatly reduced because all the polluted air cannot be inhaled into the air chamber. Lead to poor operating environment, occupational hazard, and the existence of dust secondary pollution. Wet dust removal technology, mainly spray dust removal and pharmaceutical dust removal, which can also be said to be the extension of spray dust removal technology, dust suppression agents will be added to the spray equipment, improve the dust suppression effect. The principle is to spray water to dust spots to increase humidity so that dust is no longer raised. It can inhibit the disorganized dust, but the water mist particles are large, the ability to deal with fine dust is relatively low, and the dust suppression effect is poor. Large water consumption; It can't be used normally in winter.

Key points of dust control

Through in-depth analysis of existing dust suppression technologies and full study of dust composition, it is concluded that the key points of dust control are as follows:(1) The main object of dust treatment is dust particles below 150μm, especially inhalable dust particles below 5μm in diameter, which causes irreversible damage to the human body, and is also the main source of occupational diseases such as silicosis.

(2) The current domestic dust operation site and the national provisions of labor standards, and environmental standards are far from.

(3) Power plants, steel mills and other enterprises sensitive to water content would rather pollute than use water spraying dust removal, increasing the cost of subsequent treatment.

To solve this problem, a dry fog dust suppression system was developed. Dry mist suppression systems are now proven to be the best way to deal with disorganized emissions and inhalable dust.

Dust suppression requires two conditions:

(1) There are enough dust particles and water droplets of the same size.(2) Dust particles and water droplets on both sides are in a closed area so that agglomeration can occur and continue.

The dry fog dust suppression device can produce water mist particles with a diameter of 1-10 microns, which can effectively absorb the dust suspended in the air, especially the inhalable particles with a diameter of less than 5 microns, so that the dust is settled by gravity, so as to achieve dust suppression.

Dust pollution is caused by: when the material falls, due to the large fall, strong impact, resulting in a large number of dust particles diffused into the air. Particles larger than 10 microns in diameter stay in the air for a shorter time and fall to the ground faster. Particles less than 10 microns in diameter can be suspended in the air for a long time. In order to thoroughly control the pollution source. It is necessary to study the theory of dust filtration.

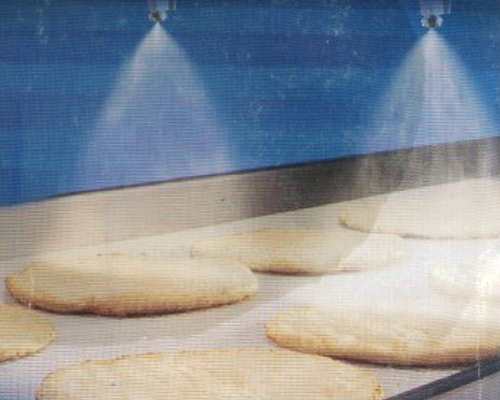

It has been proven that dusts can become larger when they are bonded by water or chemicals, but the tniest dust clumps together only when the droplets are very small (such as water mist) or when chemicals (such as surfactants) are added to reduce the surface tension of water. If the water mist particle diameter is larger than the dust particle, the dust only follows the airflow around the water mist particle, and there is little or no contact between the water mist particle and the dust particle, thus the dust suppression effect cannot be achieved. If the size of water mist particles is close to that of dust particles, dust particles collide with water mist particles along with airflow and are bonded together (as shown in the figure). The smaller the water mist particles are, the more likely they are to coalesce. As the coalescing dust becomes larger and heavier, it is easy to land. The "filtering" effect of water mist on dust is thus formed.

In order to improve the efficiency of dust collection, studies have proved that:

1. Dust catching efficiency is proportional to the relative speed of water mist and dust airflow.2. Dust catching efficiency is inversely proportional to the diameter of water mist particles.

3. The addition of surface activator will improve the dust catching effect.

To capture airborne dust smaller than 10 microns, the water mist must be smaller than 10 microns in diameter.

Dry fog dust suppression device has unimaginable dust suppression capacity: dust suppression efficiency in the dump room, screening tower, belt conveyor transfer tower has reached more than 90%, especially in capturing the size of about 5 micron inhalable dust has incomparable advantages of other dust suppression equipment. Widely used in ports, docks, power plants, steel mills, mines, petrochemical and other unorganized discharge places fixed pollution sources of closed or semi-closed space, such as: dump room, screening tower, transfer tower, crusher and so on.

Main characteristics of dry fog dust suppression:

1. Dust control at the source of pollution -- dust point;2. High dust suppression efficiency, no secondary pollution, no need to clean ash, for dust below 10 & 2.5μm can be inhaled and can enter the lung

Treatment effect up to 96%, avoid silicosis harm;

3. The water mist particles are dry mist, forming a thick and dense fog pool at the dust suppression point;

4. Energy saving and emission reduction, small water consumption, and the weight ratio of material is only 0.02%-0.05%, which is the water consumption of traditional dust removal

1/10-1/100, no calorific value loss of material (coal);

5. Small footprint, automatic PLC control, saving capital construction investment and management costs.

The dry fog dust suppression device improves the automation level and product quality of environmental protection industry, reduces the dust pollution to the atmosphere, improves the surrounding environment and the working environment of the field workers, reduces the occurrence of occupational diseases, and creates a wide range of social and economic benefits.

Applicable fields

Power plant/steel plant dumperPort ship unloader

Port loader

Bunker plough

Wind power coal separator

Impeller feeder

Belt turning point

Leather head chute

Discharge port of crusher

Truck loading/unloading port

The loading floor

Sieve tower

Circular stocker and reclaimer

Vibrating screen

other

Dry mist dust suppression system

Mattel Spray's dry mist system is highly stable and modular. The core of the system lies in our high quality nozzle - ultrasonic air atomizing nozzle, which is also what we usually call dry fog generator.Through research and experimentation, Mattel spray designs the optimal mechanical resonator, also known as the ultrasonic oscillator. The water used in the dry mist system is the water containing small bubbles namely ordinary water. Let the water enter the resonant cavity of a mechanical device, under the action of high pressure air, the vibrator in the resonant cavity produces ultrasonic vibration, its frequency f> 20 KHZ. At this time, the tiny bubbles in the water inside the cavity produce cavitation phenomenon under the action of sound intensity: that is, the tiny bubbles burst, and the pressure of tens of thousands of MPa is generated around them. It is this pressure that tears the water into hundreds of millions of micron-sized droplets, which are blasted out of nozzles by high-pressure jets to form plumes of mist.

In the high-speed video, a 2-micron droplet directly spans a distance of 2 meters. Any dust particles surrounded by a dense fog have no chance of escape. Spray dust suppression uses very little water, no chemicals, and does not increase the overall moisture content of the transported material by more than 1/10,000. The principle is mainly based on the collision of water and dust particles of the same size, condensing, growing in size and quality, condensing into larger and heavier powder falling. There was nothing special about the whole process.

Mattel spray ultrasonic atomizing nozzle has many advantages, unique structure makes this nozzle in the actual use of very stable, and long life.

① Only low pressure water and air can produce atomization effect of less than 10μm

② The circulation channel is large, thus greatly reducing the blockage

(3) In the work, the nozzle vibrator vibrates at high frequency, which can realize self-cleaning function

④ All made of stainless steel, no internal moving parts

Related products:

.jpg)

.jpg)

.jpg)

.jpg)