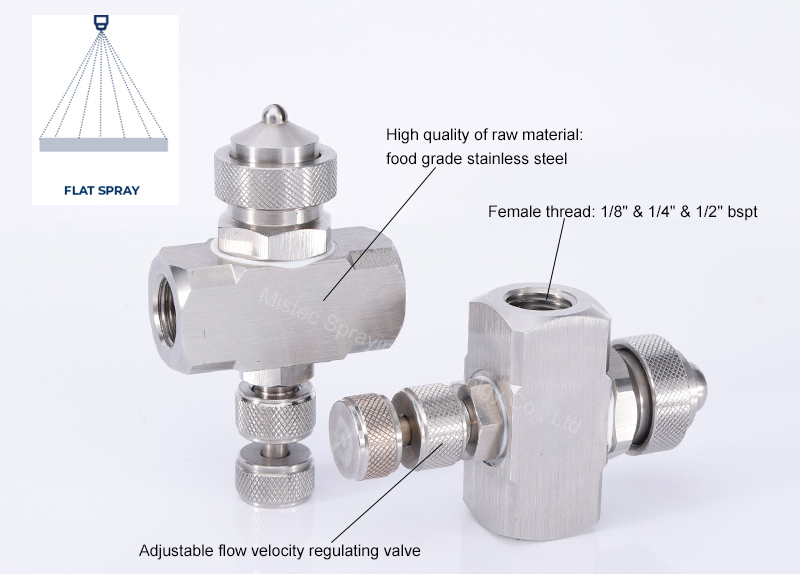

Nozzle selection basis: nozzle type, spray Angle, flow rate, pressure, coverage, impact force, viscosity, temperature, material, installation form, etc., hollow cone nozzle: spray droplet particles are small, atomization is good, water particles are fine and uniform, impact is relatively small, suitable for phosphating process.

Nozzle arrangement: Install a number of atomizing nozzles in a certain arrangement on the ring pipe composed of the outer size of the workpiece, surround the workpiece, so that when the workpiece passes through the spray area, all the surface can be sprayed by the tank liquid, and the entire spray area, all the surface can be sprayed by the tank liquid, the entire spray area should be evenly arranged spray to ensure the process time and effect of spray washing.

As we all know, electrostatic spraying equipment is composed of spray gun, spray cup and electrostatic spraying high-voltage power supply. How to use the atomizing nozzle size reasonably when using the spray gun?

1, the general spray equipment has several different sizes of the atomizing nozzle, according to the size of the atomizing nozzle, choose the right nozzle, so as to greatly improve the efficiency of the nozzle.

2. When spraying to the object corner, use the atomizing nozzle to make the spraying effect more uniform.

3. The object is relatively small, to use a small atomizing nozzle, the spray effect is more uniform, electrostatic spraying equipment with a large nozzle will not spray fine, will not improve work efficiency.

4. The surface area of the spray plate is relatively flat, and the use of large atomizing nozzle can save time and the spray effect will be better.

5. If the object has a fan-shaped area, it is best to use a fan-shaped nozzle.

In addition to the spray painting effect, the spray painting should be used reasonably, which also has a great impact on the technical requirements of the operator.

For example: the moving speed of the spray gun, which requires a certain spraying experience of the operator to control, the distance between the nozzle and the object to be painted, to be moderate, the distance is appropriate to get the desired electrostatic spraying equipment painting effect.

.jpg)

.jpg)

.jpg)

.jpg)