Ultrasonic dry mist nozzle has excellent dust suppression effect in dry mist dust suppression system. The ultrasonic dry mist nozzle can produce water mist particles with a diameter of 10μm, which can effectively absorb and aggregate the dust suspended in the air, and then settle down by gravity, so as to achieve dust suppression.

The existing dust removal technology mainly includes mechanical dust removal, dry dust removal, wet dust removal and electrostatic dust removal. At present, there is no effective method for dust control in the unorganized discharge environment with large area and many dust producing spots.

1. Characteristics and limitations of existing dust removal technology

At present, the widely used dust removal technology mainly falls into four categories: mechanical dust removal, dry dust removal, wet dust removal and electrostatic dust removal.(1) Mechanical dust removal technology

Mechanical dust removal is to use the structure of the dust collector to change the speed of airflow, the direction of movement of dust and gas separation sedimentation device, including: gravity settling chamber, inertial settling chamber, cyclone dust collector three types. The disadvantages of mechanical dust collector are low efficiency, large occupation area, high cost, rough equipment and short service life. Mechanical dust collector can be used in high temperature, corrosion, high humidity of flue gas dust, but the removal efficiency of dust particle size below 15μm is low. Generally only used for dust removal system in the primary dust collector.

(2) Dry dust removal and electrostatic dust removal technology

Dry dust removal and electrostatic dust removal are two kinds of technology is the first dust gas absorption into the dust collector, after purification treatment, the clean air is discharged into the atmosphere. The dust removal effect is better for the dust-bearing gas that has entered the air absorption chamber. However, for the open or semi-open unorganized discharge of pollution sources, the dust gas can not be effectively absorbed, and the overall dust removal effect is low.(3) Wet dust removal technology

Wet dust removal technology is mainly spray dust and chemical dust removal. Chemical dedusting is also an extension of spraying and cleaning dust. Dust suppression effect can be improved by adding dust suppression drugs to spraying water. Its principle is: to dust point spray water, so that the humidity of the material increases, and not easy to fly, at the same time to fly out of the dust for washing settlement. It has a certain effect on disorganized dust discharge, but it has a low ability to deal with fine dust, resulting in poor overall effect. At the same time, the water consumption is large, and the sewage treatment after spraying is difficult, users are difficult to accept.Through in-depth analysis of the existing dust suppression technology, it is found that the widely used dust control difficulties are concentrated in the following two points:

(1) The main object of dust treatment is inhalable dust with a particle size of less than 150μm, but the dust below 10μm can not be treated by the existing dust suppression technology.

(2) The current working environment standard of dust in China is 10mg/m³, which is far from the environmental protection standard of M3.5mg /m³.

Introduction of 2 micron dry fog dust suppression technology

2.1 Principle of dust suppression by micron level dry mist

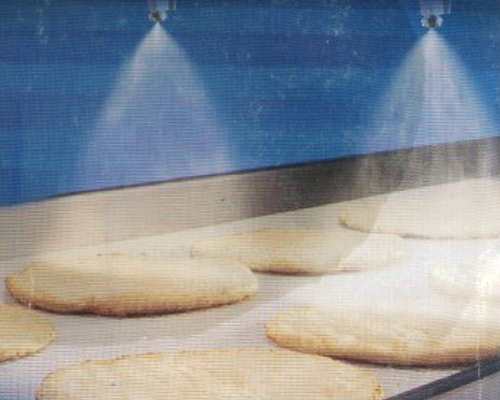

When water mist particles are similar in size to dust particles, the probability of adsorption, filtration and condensation is the largest. As well as the study of dust emission fluid mechanics as a theoretical basis, developed dry fog dust suppression system.The ultrasonic dry mist nozzle of the micron level dry mist dust suppression device can produce water mist particles with a diameter of 10μm, which can effectively absorb and aggregate the dust particles suspended in the air, especially the dust particles with a diameter of 5-10 μm that can be inhaled, and then settle down by gravity, so as to achieve dust suppression.

2.2 Experimental analysis of dust suppression by micron dry mist

When the diameter of water droplets is larger than that of dust particles, dust only follows the airflow around water droplets, and there is little or no contact between water droplets and dust particles, thus dust suppression cannot be achieved. If the size of fog particles and dust particles are close, the surface tension of water will be reduced, and it is easy to make dust particles and fog droplets collide and contact and bond together. As the particle size of fog drops becomes smaller and smaller, the probability of condensation becomes larger and larger, and the "filtering" effect of water mist on dust is formed. When the size of water mist particles and dust particles is the same, the water mist particles and dust particles are most likely to coalesce, begin to settle under the action of gravity, and finally fall to the ground.When a large number of fine water droplets form a fog, completely covering the dust point, a very good dust suppression effect will be achieved. Dry fog dust suppression nozzle to the water mist into 10μm of water mist, in the dust point above the formation of fog completely cover the dust point, so that when the material dust, dust completely into the fog, fully combined with the water mist, and gradually increase, in the effect of gravity fall to the ground.

Practical application of 3 micron dry fog dust suppression

4 micron dry fog dust suppression advantage

Compared with traditional dust removal device, micron dry mist has the following advantages:(1) Dust treatment of dust points at the source of pollution;

(2) High dust suppression efficiency, for inhalable dust less than 10μm treatment effect of more than 90%.

(3) Water mist particles are delicate, and the weight gain ratio of moisture to material is 0.02% ~ 0.05%, which can be ignored basically. Dense fog pool is formed in the dust suppression point, and there is no calorific value loss to the material (coal).

(4) Small water consumption, no secondary pollution;

(5) small footprint, low energy consumption (electricity consumption is 20% of the traditional bag dust, water consumption is 20% of the traditional spray dust);

(6) Small equipment investment, low operation and maintenance costs;

(7) pollution sources that can be used in unorganized discharges, confined or semi-confined Spaces;

(8) Greatly reduce the probability of coal dust explosion;

(9) It has cooling effect on workshop temperature.

The main characteristic of the micron scale dry mist dust suppression system is that it breaks through the traditional dust suppression method and saves the dust collection, pipeline transportation and dust post-treatment process. Directly in the dust dust position for suppression, from the source of dust treatment. Applicable to any industrial and mining, any nature of dust. Open or semi-open unorganized emission pollution sources (such as dump room, loading basket, slag, stoker and retractor, ship unloader, loader, stoker and retractor, coal feeder, etc.) after treatment, the on-site dust concentration can be stable below 10 ~ 50mg/Nm3 (depending on the initial dust concentration of different materials). Even the pollution source of closed unorganized dust discharge (such as crushing machine room, screening building, belt transport and transfer station, etc.) can reach below 3.5-10mg /Nm3 (depending on whether the closure is good or not).

The function and performance of the micron dry mist dust suppressant are better than the traditional dust suppressant, energy-saving and environmental protection, small water consumption and low operating cost. The popularization and application of this device is of great significance to improve the technical content of dust suppression equipment in China, control dust pollution and promote the technological progress of the industry.

.jpg)

.jpg)

.jpg)

.jpg)