What is a high pressure water mist fire extinguishing system? -- Working principle

High pressure water mist fire extinguishing system is made of stainless steel, corrosion resistant, water as fire extinguishing agent, safety and environmental protection, the whole system does not need a huge storage water supply equipment, because it consumes very little water, water consumption is only 1% of the spray system, fire extinguishing efficiency is 200-300 times; It has the effect of cooling and asphyxiation. It can wash the smoke and gas, shield the thermal radiation, increase the visibility of the fire scene, and facilitate the evacuation and evacuation of fire personnel.

The working pressure of the whole system is 10-21MPa. It can be linked with the automatic alarm system. It has three control modes: automatic, manual and mechanical emergency.

1.High pressure water mist extinguishing device system setting requirements

1. The fire control pipe network shall be welded, and the pipe material shall be made of national standard 304/316L;

2. After pipeline welding is completed, all pipelines shall be pickled by pipe network; Remove welding slag, pickling using stainless steel special acid lotion;

3. After pipeline installation, pressure test should be carried out on the whole pipeline system. For large pipeline system, pressure test can only be carried out on one area at a time;

4. Measure the system pressure through the pressure test device. Working pressure x 1.5= test pressure, hold for 5 minutes.

02. High pressure water mist extinguishing device applicable place

First: public and office high pressure water mist system can protect both office and large public areas. High pressure water mist nozzle, fast response, the spray of water absolutely no harm to the human body and can quickly and effectively inhibit fire.

Second: A large number of experiments in electrical places prove that high pressure water mist fire extinguishing system can be applied to protect electrical equipment places, and reduce the loss of fire to a minimum.

Technical space equipment, such as machinery and cable tunnels, are important for the normal operation of subway machines, and in case of fire, it is difficult to access technical space. The system fills the entire space with a fine mist, quickly controlling the fire in its early stages and minimizing the damage.

Fourth: the tunnel in the tunnel is very dangerous, is also prone to fire, and high pressure water mist fire extinguishing system can protect the safety of the tunnel, can control and eliminate the fire in the first few minutes of the fire, but also can protect personnel from injury.

03. Work Flow

1. Principle of open-type system software

In the quasi-working condition, the high-pressure water mist fire extinguishing system maintains a certain working pressure from the pump group entrance to the pipeline network in front of the regional valve. When the working pressure is less than the starting working pressure set by the stabilized pump, the stabilized pump starts to keep the system software pipeline network stable working pressure. When the working pressure is still not up after the stabilized pump operates for a certain time, the main valve will start the stabilized pump and terminate. A water refill solenoid valve is set at the inlet pipe of the water storage tank. Water resources enter the water storage tank after passing through the filter device and the water refill solenoid valve. The water storage tank is equipped with a liquid level controller to maintain the automatic control system for the water level of the water storage tank. The water refill solenoid valve opens at the low water level of the water storage tank and closes at the high water level.

2. Closed wet system software principle

Under the condition of quasi-operation, the high-pressure water mist automatic fire extinguishing system maintains a certain working pressure in the pipeline network from the pump group inlet to the nozzle. When the temperature of the laminated glass bubble with the nozzle closed exceeds the position temperature, the working pressure of the laminated glass bubble crushing pipeline decreases. When the working pressure is less than the set starting working pressure of the stabilized pump, The starting of the regulator pump keeps the stable working pressure of the system software pipeline network. When the working pressure of the pipeline network is still not up after the operation of the regulator pump exceeds a certain time, the main valve starts the regulator pump and terminates. The feedback mechanism of the flow control valve emits the data signal. After receiving the feedback data signal, the server opens the sprayer display light in linkage.

04. Principle of high pressure water mist fire extinguishing

High pressure water mist has the dual fire extinguishing mechanism of efficient cooling and rapid suffocation, forming a special state between liquid and gas. The water consumption is 1% of the traditional fire extinguishing means, and the efficiency is 200-300 times.

① Balanced surface cooling, efficient heat absorption;

(2) Asphyxiation and fire extinguishing, and only occur around the fire source;

(3) Impact emulsification and dilution; Blocking thermal radiation; Wash smoke and exhaust.

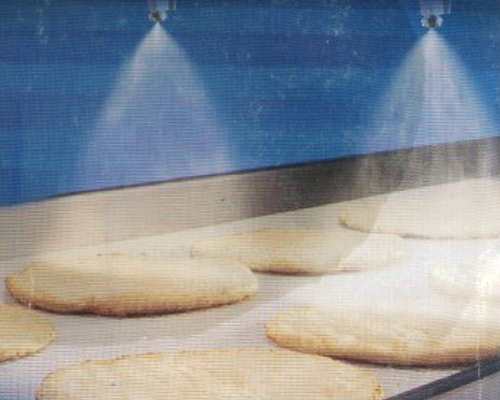

Water (pressure above 10MPa) from a special material nozzle spray, the formation of particle size in 10~100μm water mist, high pressure ultra-fine water mist particle size more than 10μm below, after the fire quickly vaporized, the volume can expand 1700~5800 times, absorb a lot of heat, the combustion surface temperature rapidly reduced; At the same time, water vaporizes and forms water vapor, which will surround and cover the combustion area as a whole, making the combustion asphyxiate due to lack of oxygen.

.jpg)

.jpg)

.jpg)

.jpg)