The core executive components of water mist fire suppression systems are the water mist nozzles which produce expected mist to suppress the fires. Just as the introduction of Water Mist Nozzles for Fire Suppression Systems, there are several standard to classify the water mist nozzles, such as high/ intermediate/ low pressure water mist nozzles, automatic/ non-automatic water mist nozzles, etc.

Firefighting is a multidisciplinary science and the mechanism of fire suppression is very complicated. As a manufacturer of spray nozzles, Mistec has a wide knowledge of different types of nozzles and we know how to produce mist. Operating pressure, flow rates, K factors, spray droplets, coverage, spray momentum, etc., as regarding the important factors to affect the performance of water mist nozzles and therefore affect the performance of whole system, we try our best to be rigorous.

Our Interests in Water Mist nozzles are as following:

I. High performance Water Mist nozzles

1. Optimized design structure that require less energy to produce water mist meanwhile maintain a good performance of fire extinguishing.

2. product seriation: study and design different Water Mist nozzles- different flow rates at operating pressures with different droplets, coverage, intensity and momentum of water spray, according to different applications and test their ability to kill fire.

3. Life time, material, etc.

II. Machining technique and quality control in mass production.

III. Real fire tests, data collection and analysis, CFD and persistent improvement.

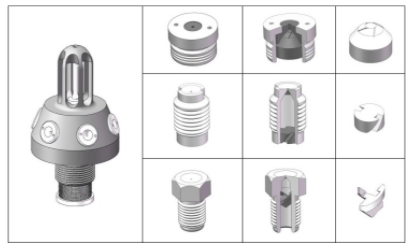

In this article, we are going to introduce several water mist nozzles in the market with different structures, design features and spray performance. We only focus the structural features that related to producing mist while ignore the various types of shape that would affect the flow distribution and coverage.

Four types water mist nozzles would be introduced:

I. Whirl Jet Type

II. Direct Jet Type

III. Impingement & Deflect Type

IV. Two Fluid Type

I. Whirl Jet Type

Utilizing specially designed whirl structure to make water speed up and swirl around, then spray out of the orifices to produce expected mist. There are various types of whirl structures to produce mist, please visit https://www.Mistec.cn/page27.html?article_id=29 for reference. Besides the structures in the article, still there are many other designs, such as using a spring as swirl core in the micro nozzles.

The velocity of swirling water can be decomposed into axial velocity and tangential velocity, which determined by input pressure and nozzle structures, would therefore affect the spray momentum, droplets size, flow distribution, etc. Since the whirl structures, the water can obtain a high tangential velocity at the centrifugal force, this type of water mist can produce can produce very tiny droplets. It is easy to adjust the whirl structures to get different combination of flow rates, spray momentum, droplet size, spray angles, this kind of nozzles are the most widely used water mist nozzles.

II. Direct Jet Type

Straight hole or small ditch structures are adopted in this type of water mist nozzles. Water is pumped to high pressure and pass through the straight holes or small ditches at very high velocity and then spray out from the orifices and be sheared into small droplets. Since the structure is very simple and less energy lost in the process of energy transfer, the mist produced by this kind of nozzle can obtain an outstanding spray momentum that is a very important factor to fire fighting. Bigger spray momentum means larger coverage, stronger ability to penetrate the fires.

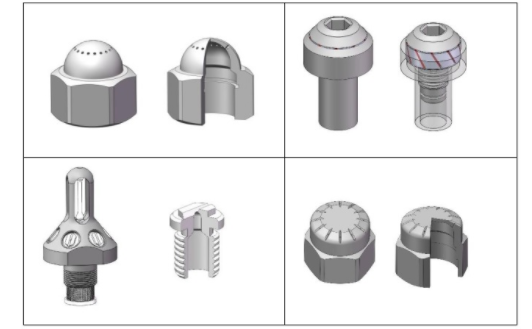

III. Impingement & Deflect Type

Impingement & Deflect Type water mist nozzles are more traditional as firefighting sprinkler and industrial nozzles. The structure of this type of nozzle is simple but can produce small droplets at low to intermediate pressure which can meet the definition of water mist.

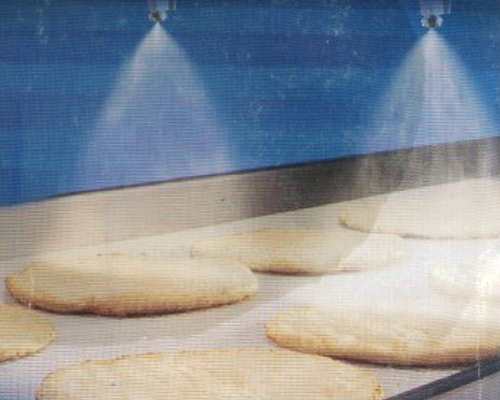

IV. Two Fluid Type

This type of water mist nozzles utilizing compressed air to mix with water can produce very tiny droplets which have strong ability to rapid cooling and evaporation. For general compressed air assisted nozzles, the diameter of their droplets can be less than 50 microns while for some specially designed two fluid water mist nozzles, such like ultrasonic enforced air atomizing nozzle, the droplet diameter would be around 10 microns.

.jpg)

.jpg)

.jpg)

.jpg)