Open flames, red-hot cooking surfaces, and a heavily grease-laden environment combine to make the modern commercial kitchen a potentially dangerous fire hazard. Kitchen fires spread quickly and have proven to be very difficult to extinguish, making them the leading cause of structural fire damage worldwide.

Cooking oil fires, compared to other types of liquid fuel fires, are difficult to extinguish,

because they burn at high temperature and re-ignite easily. Fires that involve cooking oils or fats are designated "Class K" under the American system, and "Class F" under the European/Australian systems. Though such fires are technically a subclass of the flammable liquid/gas class, the special characteristics of these types of fires, namely the higher flash point, are considered important enough to recognize separately.

Causes for Kitchen Fires

I. Improper operations make the cooking oil at a high temperature constantly

II. Flame triggered by fuel leakage in kitchen

III. Grease in ducts is a big hidden danger of fire

Method to Kill Kitchen Fires

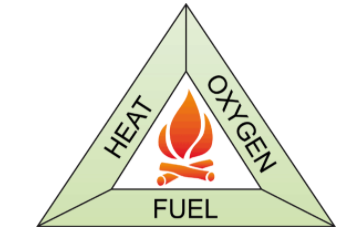

Three necessary elements to fires are fuel, heat and oxygen. To kill a fire is to eliminate at least one of the three elements. In the article of Water Mist Nozzles for Fire Suppression Systems (refer to https://www.mistec.cn/page22.html?article_id=30), we have briefly introduced the benefits of water mist systems. For kitchen fires, the mist systems are still available.

Two remarkable Mist Systems designed to suppress the kitchen fires will introduced in this article- Wet Chemical Mist System and Water Mist System. Different extinguishing agent features the two mist systems.

I. Wet Chemical Mist System

It is a kind of water based mist system, utilizing a potassium carbonate based or similar extinguishing agent that specifically designed to extinguish grease laden fires such as those found in commercial cooking areas.

The agent suppresses a fire in three ways:

1. The agent interrupts the chemical chain reaction causing combustion, thus extinguishing the fire.

2. The agent is discharged in a very fine mist, cooling the fire to below its auto-ignition temperature.

3. The agent reacts with grease to form a foam-like layer commonly called saponification that starves the fire of oxygen, stopping combustion and preventing re-ignition.

Usually in wet chemical mist systems, cylinders are used for pressure supply. The operating pressure of the mist nozzles are around 10-15 bar. Nozzles caps are needed to preventing from logging problem by grease.

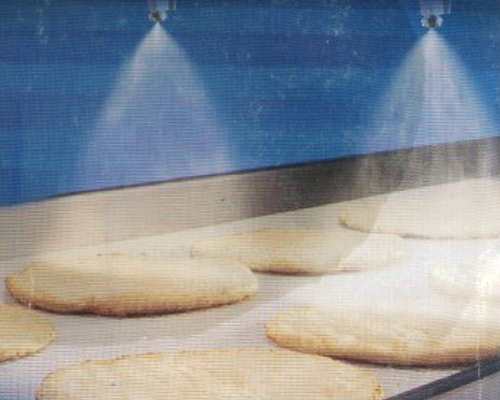

II. Water Mist System

Pure water is used as the extinguishing agent. Full-scale fire experiments demonstrated that the water mist fire suppression systems developed in the present work were capable of extinguishing cooking oil fires and preventing their re-ignition. The predominant extinguishing mechanism was the cooling of the fire plume and the wetting/cooling of the oil. Extinguishing cooking oil fires requires flame extinction over the entire surface at once

and rapid cooling of oil below its auto-re-ignition temperature to prevent re-ignition.

Usually intermediate Pressure (12.1-34.5 bar) to high pressure (>34.5Mpa) is needed in water mist systems to get very fine droplets that they are light enough not to penetrate the oil surface and can cool the oil rapidly. Besides droplet size, spray momentum, spray coverage area and flow rate are also most important factors that determine the effectiveness of a water mist system for extinguishing cooking oil fires. The discharge of water mist does not cause oil to splash outside the fryer.

.jpg)

.jpg)

.jpg)

.jpg)