Application of spray nozzle in food industry

spray nozzle with its wear resistance, heat resistance, pressure resistance and spray flow, spray Angle, Angle of accuracy makes it can meet the production needs of food sections, to achieve a diversified application in the food industry. In the food industry, the spray nozzle is very widely used, whether it is the factory environment, raw material pretreatment, or the production process and finished product packaging, small spray nozzle always plays an important role. Mattel spray nozzle for you to introduce the specific application of spray nozzle in the food industry.

(1) spray nozzle can be used for cleaning in the food industry

Food processing used in the conveyor belt, bottles, buckets, tanks, turnover box, cloth and other appliances can use the spray nozzle to clean, not only save labor costs, and the cleaning effect is remarkable. The spray nozzle can also be used for cleaning and disinfection of all kinds of containers and tanks, for cleaning of production lines, cooling stations, pipelines and odor control, plant humidification, etc.

(2) spray nozzle can be used for sterilization and disinfection in the food industry

Sterilization and disinfection is an essential part of food processing, whether factories, production equipment or operators need sterilization and disinfection, so as to ensure the safety of food. Using a spray nozzle to spray or spray the disinfectant can easily and easily reach the desired area.

(3) The spray nozzle can be used for humidification in the food industry

In baked goods, flour is usually kept in a room with constant temperature and humidity, fermented for a period of time before moving on to the next process. The fermentation chamber has high requirements for humidity, generally requiring rh 75%-80% humidity. At this time, the spray nozzle can quickly help spray water to enhance the humidity, so that the production environment to achieve the desired condition.

(4) The spray nozzle can be used for coating in the food industry

Whether the distribution of flavoring agent is appropriate and uniform is the key to affect the taste of food. The spray nozzle can spray accurately and evenly so that the food flavoring agent can be sprayed evenly.

(5) spray nozzle can be used for blowing in the food industry

In the process of food packaging waiting for delivery, it is necessary to remove water droplets on the food surface and screen out defective products. At this time, the spray nozzle can spray accurately and quickly, which increases the screening efficiency.

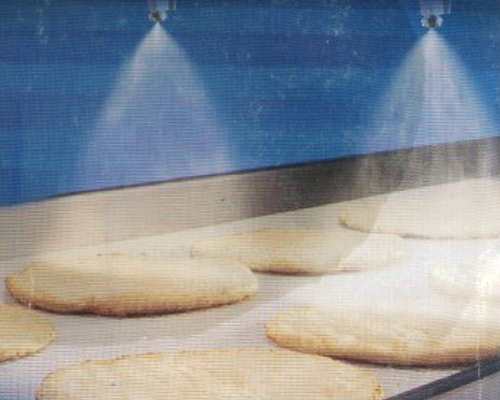

(6) spray nozzles can be used in the food industry to cut dough

Use an automatic spray gun to draw a dividing line on the dough, and shoot the water-free cream directly from an innovative spray nozzle, which can be automatically cut. The depth of the cutting line can be controlled by adjusting the pressure. This cut does not touch the dough like a cutter, making it more hygienic and reliable.

The role of nozzle in food industry

In the food industry, clip nozzle is very widely used, whether it is the factory environment, material before disposal, is still the production process and product packaging, small nozzle has been playing an important role.

Here are several nozzles used in the food industry.

1. Cleaning

Nozzle can be used for all kinds of containers and large and small tank tank cleaning and disinfection, used for production line, cooling table, pipeline cleaning, as well as odor control, plant humidification, etc.

2. Food processing

1) Cut the dough and draw a dividing line on the dough with an active spray gun; Direct injection of water-free cream from the clip nozzle, can be actively cut. The depth of the cut line can be controlled by adjusting the pressure.

It doesn't touch the dough like you would with a knife, it's cleaner and more firm.

2) The juice filled with cooling beverage water is cooled in the conveying tube. When the nozzle is hollow cone nozzle or micro nozzle, small particles can accelerate the heat exchange rate.

3) Adding spices can increase a variety of different spices quantitatively, which is the homogenization progress of commodities.

3. Food packaging

Can be used for tank cleaning, pasteurization, beverage bottle cleaning, equipment disinfection, blow dry and cooling.

.jpg)

.jpg)

.jpg)

.jpg)