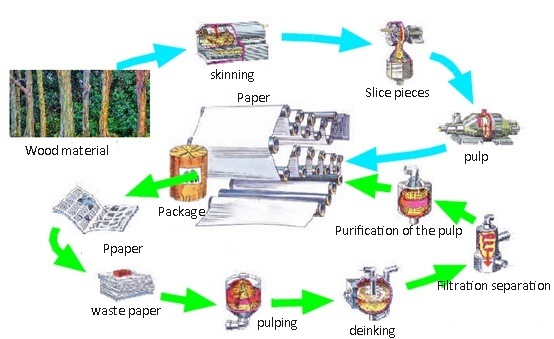

Application of papermaking nozzle in papermaking industry

The nozzle has different functions in the whole papermaking process.

For example, the nozzle is used in the dust removal, humidification, papermaking equipment cleaning, etc.

For the paper industry, paper nozzle as a precision component, from the pulp box, network press, drying and winding parts can be seen nozzle, but for the whole paper machine, nozzle is just a small part.

Nozzle applications in the paper industry mainly include:

1, Paper net washing

2, Wash the blankets

3, cutting water needle

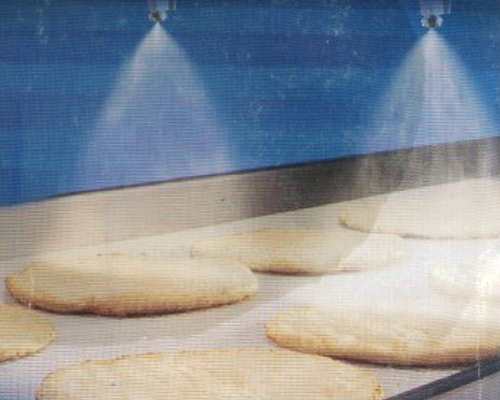

4, Humidification of paper processing plants

5, starch coating

6, flow slurry box defoaming

7, long net machine vacuum suction roller cleaning

8, Chemical injection

9, Dust control

10, moisturizing and humidifying

And other scenarios.

2, Wash the blankets

3, cutting water needle

4, Humidification of paper processing plants

5, starch coating

6, flow slurry box defoaming

7, long net machine vacuum suction roller cleaning

8, Chemical injection

9, Dust control

10, moisturizing and humidifying

And other scenarios.

Examples of nozzle use in paper industry

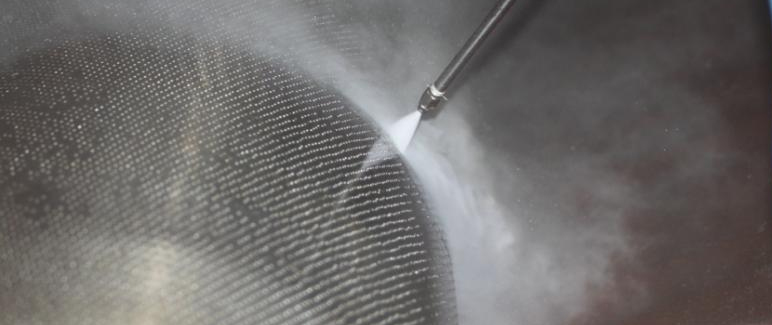

Industrial nozzle paper net washing

With the increase of speed and width of paper machine, polyester forming net is used more widely, and the cleaning quality of polyester net is required higher.

Using industrial nozzles to do paper net washing can prolong the life of polyester net, textile paste net, using industrial nozzles to remove impurities in the secondary fiber recovery, using industrial nozzles to prevent paper net from being polluted in the white water closed circulation system.

Incorrect use of nozzles can also cause other problems:

(1) Poor cleaning effect will affect the service life of wool cloth, forming net and roller;

(2) Poor spray coverage and overlap will affect the quality of paper;

(3) The use of improper nozzles leads to more waste of water and chemicals;

(4) Easy to cause unnecessary shutdown maintenance, increase operation and maintenance costs.

How to choose nozzle in paper industry

Due to the papermaking process, each link of nozzle requirements are not the same.But we can consider the nozzle from these dimensions: the materials,the flow of the nozzle, the pressure matching the nozzle, the spray angle range and spray shape of the nozzle, the spray impact force of the nozzle, high temperature and corrosion resistance, whether it is easy to install and replace, etc.

Main technical parameters of nozzles in paper industry :

Common size:1/4,3/8,1/2,3/4,1 inch

Pressure: 0Mpa-15Mpa (common pressure 1Mpa,2Mpa,3Mpa,4Mpa,5Mpa10Mpa)

Flow rate: 0L/min--1000L/min(common flow 0.5L/min,1L/min,5L/min,10L/min,20L/min,30L/min )

Spray angle: Common degrees 30°,45°,60°,90°,120°,360°(the angle can be customized according to the needs of 0-360° )

Material: Stainless steel (SS304,303,316,316L ), brass ( BRASS ), plastic ( PVC , ABS , FUD )

The above sizes are common sizes. In addition, there are 1.2-inch , 1.5-inch , 2-inch , 2.5-inch , and 4-inch nozzles.

.jpg)

.jpg)

.jpg)

.jpg)