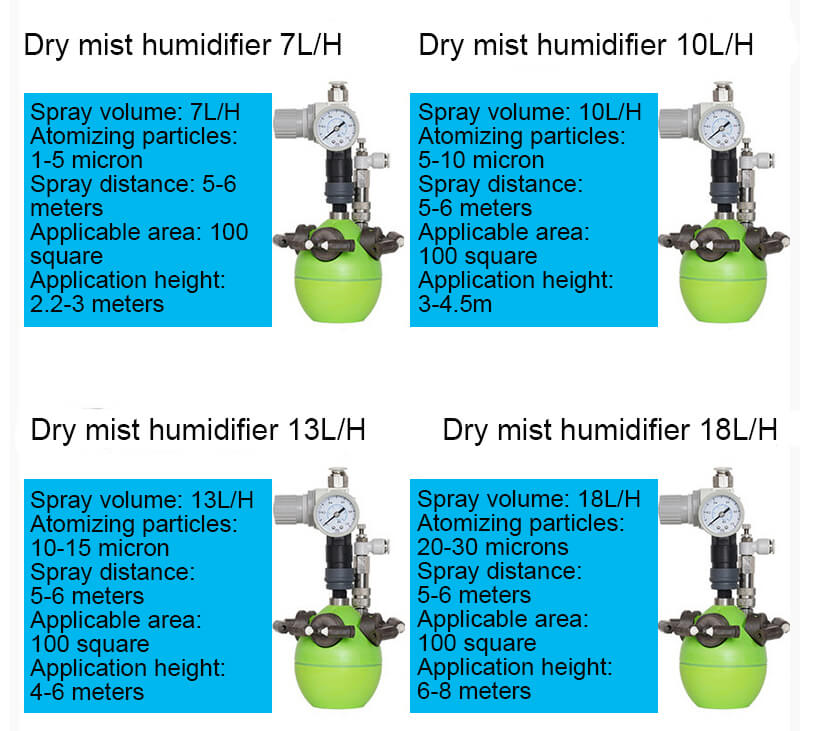

Material: Stainless steel spray set-up, plastic body, fog nozzles

Spray pattern: Fine dry fog mist spray

Spray distance: 5-6 meter

Droplet sizes: 3 to 15 microns

Air pressure: 2 to 5 bar

Liquid pressure: 0.2 to 5 bar

Flow rate: 0.9 to 12 liters per hour

Effective area: 50-150 square meters

Application: Humidifying, cooling, dust control etc

Choose it to let you have a cost-effective industrial humidification products

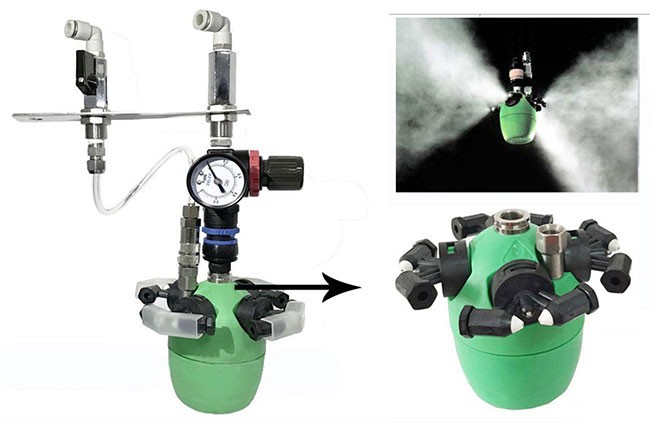

1. Four nozzles are arranged in a compact and reasonable way to achieve 360-degree multi-directional coverage.

2. The machine has its own water filter, clean atomization, nozzle is not easy to block.

3. Three-level atomization, 5-7 micron ultra-fine mist, good air absorption rate.

4. Single side air mist distance of nozzle is 5-6 meters, easily covering 100-120 square meters.

5. Small volume, no space, simple installation and maintenance, low energy consumption.

6. Nozzle adopts imported materials, high and low temperature resistance, corrosion resistance, long service life.

7. Equipped with automatic control box, it can realize the requirement of automatic humidity in the workshop, without the care of personnel.

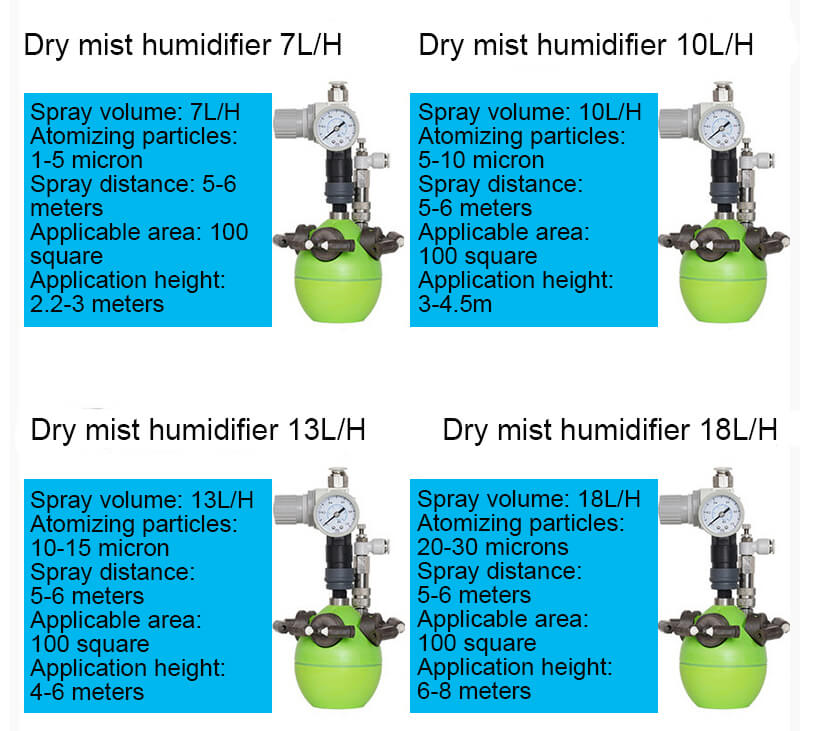

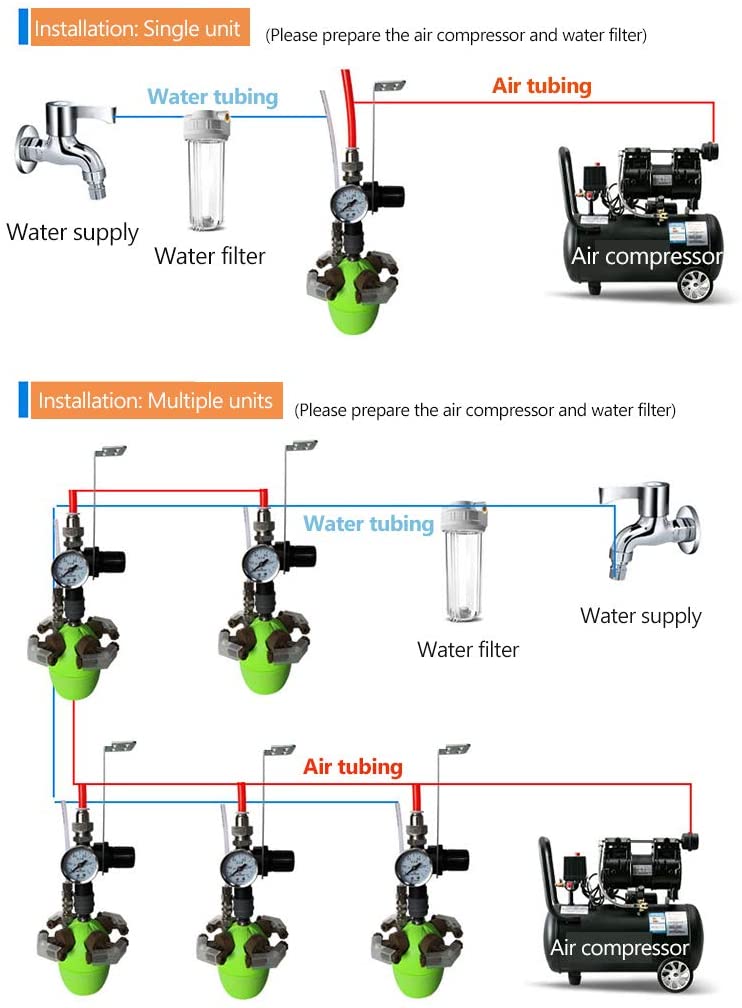

1. High precision pneumatic valve

High precision pressure valve with high quality pressure gauge, knob type control valve, free to adjust the working pressure.

2.360-degree multi-directional coverage

Four nozzle compact and reasonable layout, nozzle single side air mist distance up to 5-6 meters, easily cover 100-120 square meters.

3. The imported material of pot body is PVDF

The pot body is made of PVDF plastic with physical antibacterial properties, smooth surface, not easy to deform under low and high temperature conditions, resistant to temperature -40 to 270℃, long service life, high pressure and acid and alkali resistance.

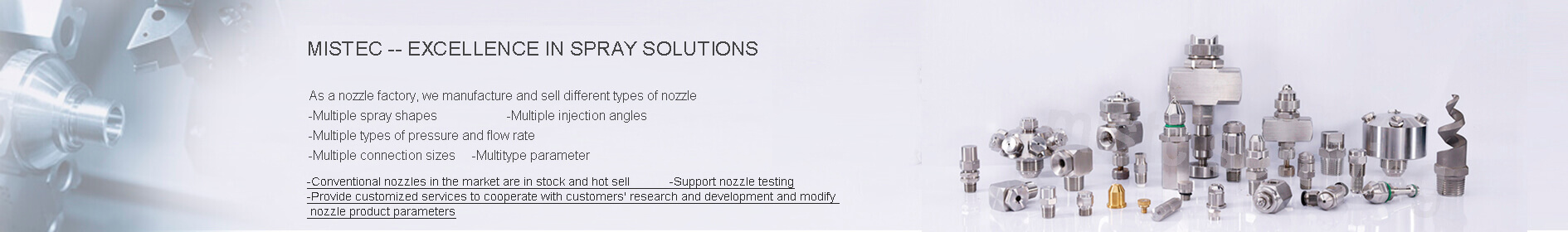

4. Crab claw nozzle

Collision structure to achieve three - stage gasification, than the ordinary two - fluid humidifier atomization finer

5. The nozzle has its own filter

The nozzle is equipped with filter net and non-blocking dry mist nozzle with high precision processing. If equipped with pure water processor, there is no need to clean the humidifier.

.jpg)

.jpg)

.jpg)

Common application:

Printing: reduce typing errors, eneven coloring, paper warping phenomenon, reduce paper transporting trouble, improve the clarity of the colour printing.

Electronics: prevent electrostatic demage, electrostatic adsorption and electromagnetic interference.

Plastic industry: reduce the slicer trouble caused by static electricity, to avoid the explosion of combustible gases

Textile industry: reduce disconnection, clothes wrinkling ad unable to shaping events; reduce fiber membrane bending trouble; reduce raw wool twining on the machine.

Paint: avoid air dust, reduce defective caused due to electrostatic bonding.

Food industry: maintain a certain humidity to protect the freshness of the food, accelerate the spped of the food maturing, avoid food cracking in a dry environment.

Farm and garden: maintain humidity balance of the mushroon room, and keep the proper humidity by the humidity sensor.

Paper industry:reduce paper blocking due to the unified specification during the transportation , prevent fire caused by tiny particles.

.jpg)

.jpg)