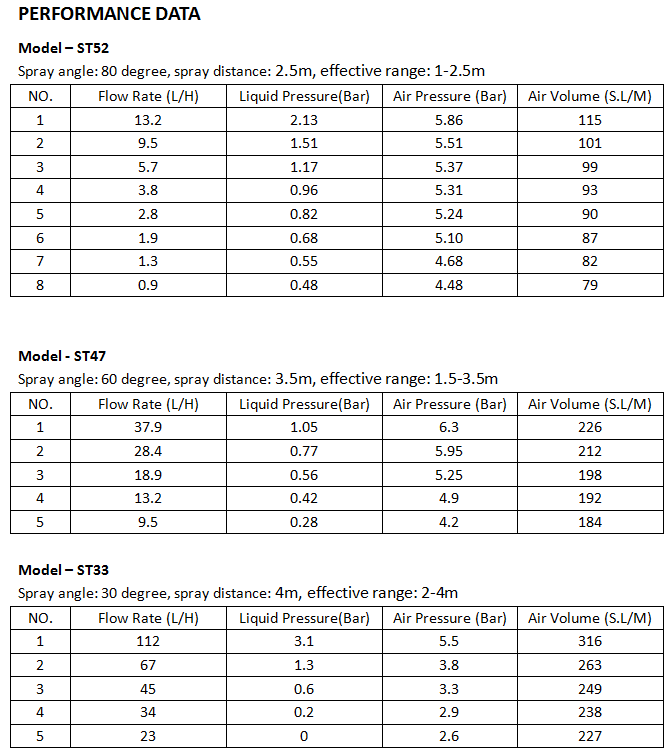

Spray Characteristics

Spray angles: 30°~ 90°, affected by water/air pressure

Flow rate: 0.94L/H ~45L/H

solid cone spray pattern with extremely fine

article size at low air pressures

Ordering Information

See below chart

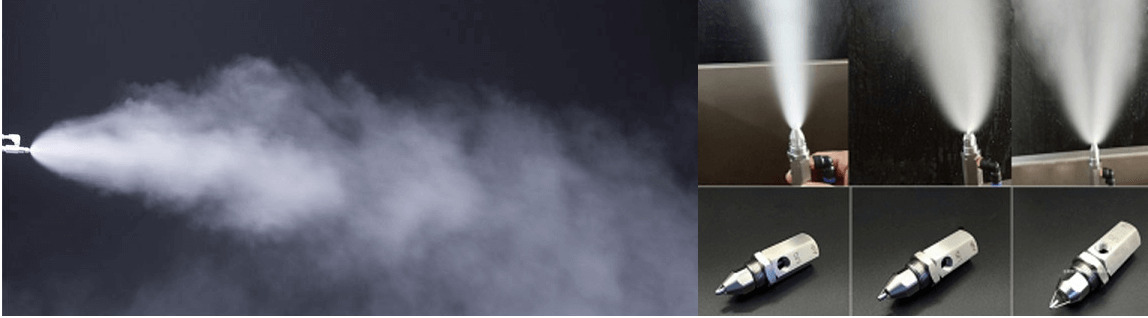

Ultrasonic misting atomizer nozzle uses the ultrasonic wave energy enhanced by the principle of acoustic wave reflection to break the cohesion of water droplets, so that the water droplets dispersed into more and smaller micro water droplets, that is, the ultra-fine water mist, to achieve misting fog effect.

The spray distance of ultrasonic misting atomizer nozzle is long, the spray shape is stable, and it is very good in the suppression of dust. At the same time, ultrasonic atomizer is also used in many industries and equipment.

Water Ultrasonic Misting Atomizer Spray Nozzle Video Demo

Spray Characteristics

Spray angles: 30°~ 120°, affected by water/air pressureFlow rate: 0.94L/H ~45L/H

solid cone spray pattern with extremely fine

article size at low air pressures

Design Features

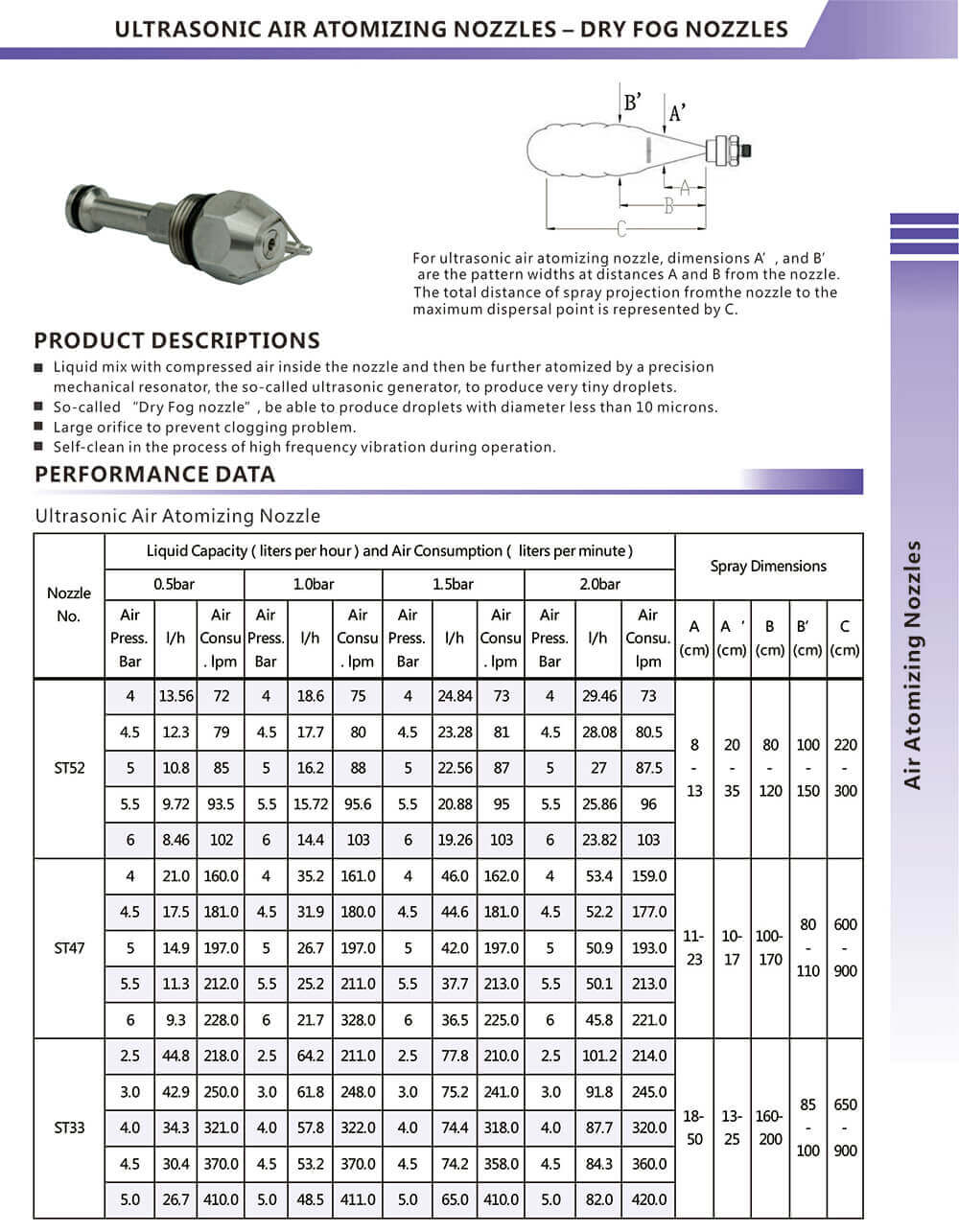

Two fluid structure design, assembly a precision mechanical resonatorProduce extremely fine droplets at low water and air pressure

Large orifice to prevent clogging problem and deterioration of the quality of atomization

Self-clean in the process of high frequency vibration

Stainless steel material, no removable parts

Come to know why ultrasonic air atomizing has the ablity to produce less than 10 um fog

Mistec's high quality ultrasonic atomizing nozzles with the ability to shear the water into extremely fine droplets--the so-called "dry fog", with droplets size 1-10 Microns. The mechanical ultrasonic nozzle has a carefully designed resonator to produce high frequency wave. Compressed air passes through the nozzle's inner bore through a convergent/divergent section at high velocities and expands into a resonator cavity where it is reflected back to complement and amplify the primary shock wave.

The result is an intensified field of sonic energy focused between the nozzle body and the resonator cap. Any liquid capable of being pumped into the shock wave is vigorously sheared into fine droplets by the acoustic field. Air bypassing the resonator carries the atomized droplets downstream in a soft plume shaped spray.

The application of ultrasonic atomizing nozzle

1. Spray dust removal application.Thermal power plant, chemical plant, cement plant, mining and other industries belt conveyor, unloading link dust control.

2. Spray humidification application.

Fine chemical industry, paper making, mushroom planting and other production links that need humidity.

3. Spray disinfection application.

Food, breeding, agriculture, etc. need sterilization and disinfection.

4. Others

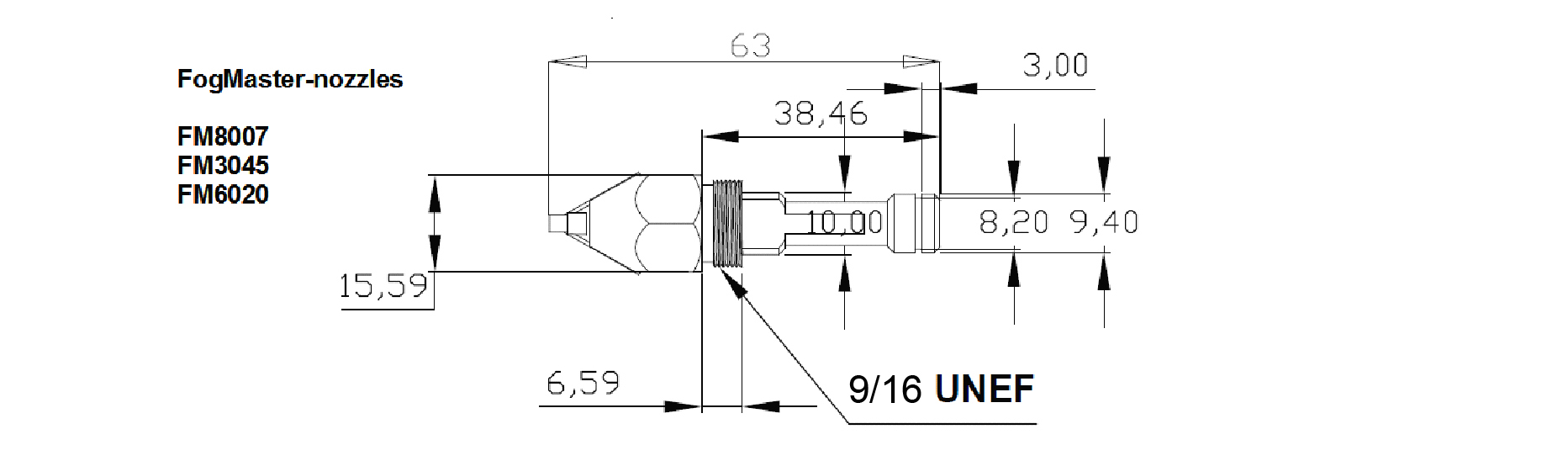

Dimension

.jpg)

.jpg)