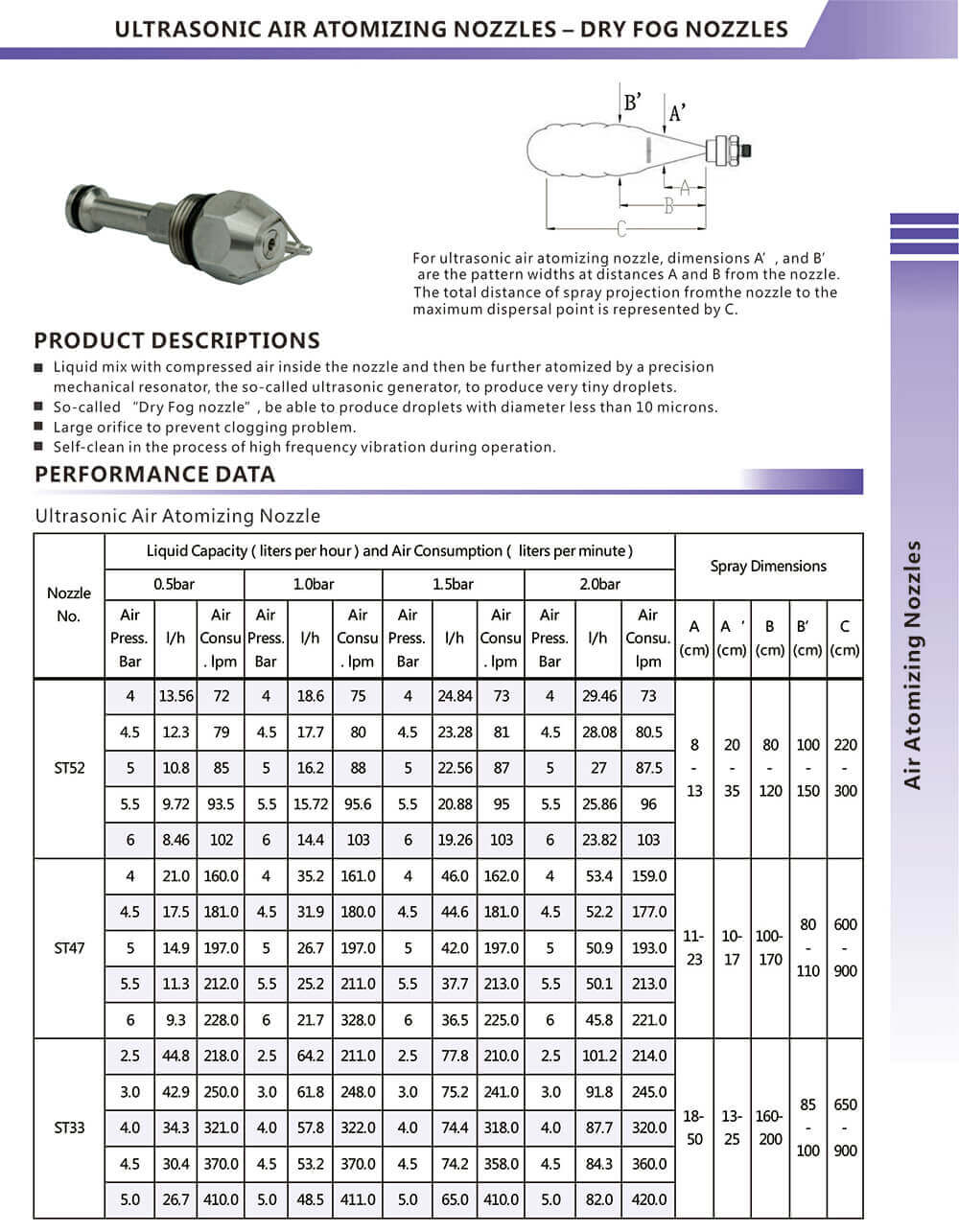

Ultrasonic Air Atomizing Dry fog nozzle

From the product structure and composition, Ultrasonic Air Atomizing Dry fog nozzle composition is actually very simple, there are 3-4 components, are the resonance cavity, shell, nozzle core, connecting rod. The atomized particle size is about 10μm.

Ultrasonic atomizing nozzle can achieve better uniformity, thinner coating thickness, higher precision. Ultrasonic spray nozzle can significantly reduce coating splash during the process of spray nozzle and realize the purpose of saving coating.

Ultrasonic Air Atomizing dry fog nozzle: the use of ultrasonic energy will be water or liquid break up, forming a few micron to more than 100 micron size of tiny particles, to achieve air humidification, liquid granulation, mixing, promote chemical reaction, nozzle, metal melting system powder and other purposes.

Ultrasonic Air Atomizing dry fog nozzle Demo Video

The reason why ultrasonic dry mist nozzle becomes dry mist nozzle is because its spray droplets are very fine, the diameter is about 10 microns.

The detail

Material:BRASS, SS, plastics (PP/PVC/PTFE), ceramics (SS), etc.

Jet Angle:30°, 60°, 80°

Inlet size:3/16'',1/8'',1/2'',1/4"

Spray pattern:Solid cone

Application:

Dust Removal , Air Control, Dust Control,Humidification

|

Categories |

Spray Angle 80° |

SV882 Spray Angle 60° |

Spray Angle 30°

|

|

Gas pressure |

5.2bar |

3.5bar |

5.2bar |

|

Water pressure |

1.5bar |

0.6bar |

1.2bar |

|

Gas consumption |

115L/Min |

260L/Min |

240L/Min |

|

Water consumption |

7.1L/Hr |

45L/Hr |

20L/Hr |

|

Atomizing granularity |

3-6microns |

4-10microns |

7-10microns |

|

Gas filtration demand |

<40microns |

<40microns |

<40microns |

|

Water filtration demand |

<50microns |

<50microns |

<50microns |

.jpg)

.jpg)